Disc Pelletizer

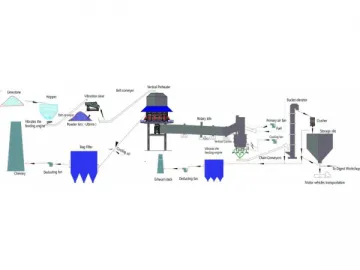

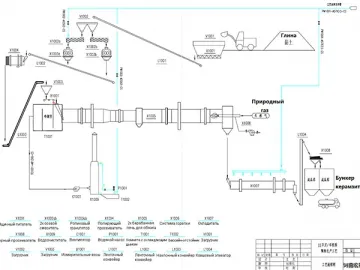

Pelletizing is the process of compressing or molding a material into the shape of a pellet. Our disc pelletizer is designed with three discharge chutes, which allows for intermittent production, increases the labor productivity significantly and decreases downtime.Driven by flexible belt, the reducer and the motor suffer from less impact and smooth. In addition, smooth startup of them can be ensured. Therefore, service time of the pelletizer is extended. Instead of foundation bolts, the disc bottom is strengthened and thickened by multiple radial steel plates, thus ensuring firmness and durability and eliminating deformation. The disc is fitted with angle spacers, which facility inclination adjustment. The framework is able to move up and down hovering over the disc body to find a proper position where high pelletizing efficiency can be achieved. Pipes in the framework is connected at the end with lapped flanges. The pelletizer is capable of preventing the pellets from being strained and tore up upon discharging. Hence, it ensures high pelletizing efficiency and high roundness and strength of the pellets.

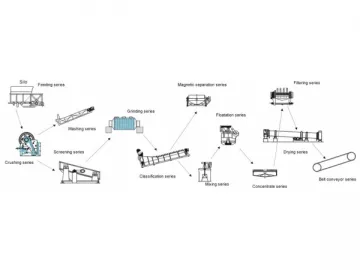

With our disc pelletizer, wide range of materials can be pelletizied including coal powder, cement, lime, shale, gangue, clay, rare earth, ammonium bicarbonate and ammonium sulfate.

Technical Parameters

| Specification (m) | Disc Rotating Speed (r/min) | Capacity (t/h) | Matched Power (kw) | Disc Inclination Range | Dimension (m) | Total Weight (kg) |

| Φ2.2 | 14.25 | 4-8 | 7.5 | 35-55 | 2.8×2.75×2.58 | 2850 |

| Φ2.5 | 11.81 | 5-10 | 7.5 | 35-55 | 3.2×2.3×3 | 3250 |

| Φ2.8 | 11.21 | 12-16 | 7.5 | 35-55 | 3.4×2.6×3.1 | 3710 |

| Φ3.0 | 11.3 | 15-18 | 11 | 35-55 | 3.7×2.7×3.3 | 4350 |

| Φ3.2 | 9.6 | 15-20 | 11 | 35-55 | 3.9×2.7×3.4 | 5110 |

| Φ3.6 | 9.1 | 18-24 | 15 | 35-55 | 4.3×3.1×4.0 | 6510 |

Links:https://www.globefindpro.com/products/55564.html