Boom Lift

BoomLift

Our DGS25Y boom lift has already been tested bythe National Construction Machinery Quality Supervision and Inspection Center.It has multiple functions, such as synchronized telescoping of multi-stageboom, basket automatic leveling, basket 180 ° swinging, proportional control ofhydraulic control system, start and brake buffering, ramp protection, optionaloverload limit protection, luffingangle protection, two-wheel steering, two-wheel drive, two shifts traveling,anti-skid traveling, 360° continuous rotation of platform, and so on.

Our boom lift works with the ambient temperature ranging from -15°C to45°C. The wind power in working state shall be lower than 6-level, with thewind speed less than or equal to 10m/s. In addition, it is applicable to noheavily oiled, flat cement, asphalt, and compacted stone roads. It is suitablefor transport with load and also lifting job, with the axle weight distributedevenly and the hanging hole placed at both ends of the drive chassis.

To adapt to dust, corrosion and other harsh environments, as well as sandblasting and spraying operations, the boom lift is provided with the bestprotection in all parts. For example, it has corrugated casing for the fueltank, sand scraping device for the working arm, protective cover for thecontrol box, cover for the central slewing platform, cover for the cable rail,and so on.

MainComponents

Drive Chassis

1. Four-wheel drive chassis

The boom lift achieves a maximum speed of 4km/h and a maximum gradeability of 14° (25%), whichmeans that it can stop, start, and will not decline in the 14° slope duringnon-working state.

Due to the hydraulic flow distribution system of the four-wheel drivechassis, it can prevent individual tire slipping due to ground reasons and furtheravoid power loss.

With a ground clearance of 245mm, the vehicle enjoys good trafficability.

2. Four-wheel steering chassis

Our boom lift can realizeall-wheel independent steering and four flexible steering modes, includingfront wheel steering, rear wheel steering, splay steering and obliquetraveling. Regardless of axle extension, these steering modes can be achieved,with the minimum outside turning radius of 4.9m.

Slewing Platform

1. The slewing platform of the boom lift is driven by hydraulicmotors and can achieve 360-degree continuous rotation. With the central rotaryjoint, the upper and lower oil-way, as well as electrical devices can beconnected.

2. On one side of the rotating platform is placed with the engine, the tray ofwhich can turn 40 degrees for easy repair and maintenance.

3. The control system is placed on the other side. Due to the coremicroprocessor and main controller, it can control various actions of vehicleson the ground, and conduct system diagnosis with the error code shown on thedisplay.

Operating Boom

1. The telescoping of the three-section boom is controlled by thetelescopic cylinder and wire rope mechanisms. With no need to split the workarm, the wire rope connector and pulley can be inspected visually and maintainedregularly.

2. The work scope of the boom is controlled by the limit switch, ensuringreliable operation with almost not failure.

Working Basket

1. The workingbasket of the boom lift is made of seamless steel pipe,providing mesh floor, high strength, light weight, and 250kg load. It can beswung 180 degrees, and automatically leveled by two balanced cylinders inseries.

2. Due to the controller, the basket can achieve two composite motions,including horizontal back and forth movement and vertical up and down movement.These complex operation modes can meet the needs of special working conditions,which can not be achieved by similar products provided by other manufacturers.

Safety Control

1. The boom lift is available with the driving confirmation system:When the rotating platform turns to the rear of the vehicle, the operator shallpress the confirmation switch and then conduct steering, walking, and otheroperations, so as to avoid accident due to error judgment of direction.

2. The foot switch can be used to control the power supply and ensure safeoperation.

3. The basket tilt alarm system gives alarm when the basket tilts over 10degrees, and locks the movement of the working arm.

4. When the gradient is greater than 5 degrees, the slewing platform tilt alarmsystem alerts and does not allow the working arm to stretch out and go down.

5. The crash barrier is designed to prevent the operator from injuries.

6. With the emergency stop button, the boom lift can be stopped when anemergency happens.

7. If the vehicle stops because of engine trouble while the working basket isin a high position, the user can put down the boom through the electricemergency pump, thus ensuring safety.

Technical Parameters

| Overall Dimension | |||||||

| Length | 10100mm | 10300mm | 12400mm | 14100mm | 15500mm | ||

| Width | Axle retracted | 2400mm | 2400mm | 2500mm | 2500mm | 2650mm | |

| Axle stretched | 2900mm | 3100mm | 3590mm | 3590mm | 3800mm | ||

| Height | 2900mm | 2900mm | 3000mm | 3500mm | 3500mm | ||

| Wheel base | 2900mm | 3100mm | 3500mm | 3500mm | 3750mm | ||

| Ground clearance | 245mm | ||||||

| Weight | 12200kg | 13500kg | 16200kg | 18100kg | 19800kg | ||

| Model | DGS18Y | DGS21Y | DGS25Y | DGS28Y | DGS30Y | |||||

| Rated load | 250kg | 250kg | 250kg | 250kg | 250kg | |||||

| Maximum platform height | 18m | 21.5m | 25m | 28.5m | 30.1m | |||||

| Boom | ||||||||||

| Boom telescoping | Length | 16.86m | 20.1m | 23.98m | 27.4m | 28.9m | ||||

| Speed | 50s | 60s | 60s | 75s | 85s | |||||

| Boom luffing | Angle | -12°~72° | -12°~72° | -13°~72° | -13°~72° | -13°~72° | ||||

| Speed | 50s | 50s | 60s | 60s | 70s | |||||

| Max. horizontal extension | 15.3m | 18.8m | 19.5m | 20.3m | 20.7m | |||||

| Working Platform | ||||||||||

| Swinging angle | ±80° | |||||||||

| Slewing Platform | ||||||||||

| Slewing angle | 360° continious | |||||||||

| Slewing speed | 0-1r/min | |||||||||

| Tail turning radius | 2650mm | 2700mm | 2730mm | 2810mm | 2905mm | |||||

| Traveling Mechanism | ||||||||||

| Traveling mode | Straight, oblique driving, splay steering | |||||||||

| Traveling speed | High | 0-4km/h | ||||||||

| Slow | 0-2km/h | |||||||||

Links:https://www.globefindpro.com/products/55731.html

-

3200 Passive Keyless Entry System

3200 Passive Keyless Entry System

-

SD Card Car DVR

SD Card Car DVR

-

3300 One For All Smart Key Engine Start-Stop System

3300 One For All Smart Key Engine Start-Stop System

-

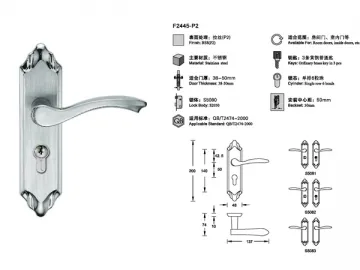

F2445-P2 Stainless Steel Door Lock

F2445-P2 Stainless Steel Door Lock

-

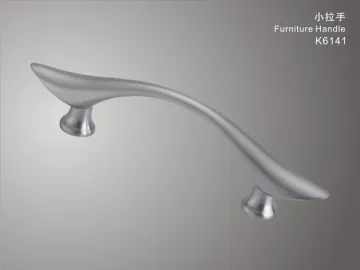

K6141 Cabinet Handle

K6141 Cabinet Handle

-

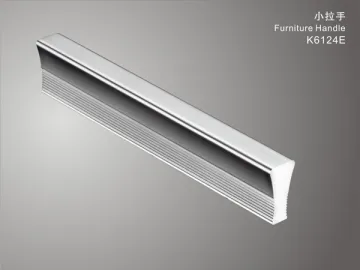

K6124E Cabinet Handle

K6124E Cabinet Handle

-

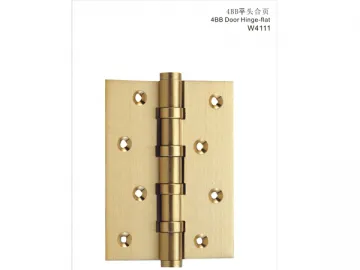

W4111 Door Hinge

W4111 Door Hinge

-

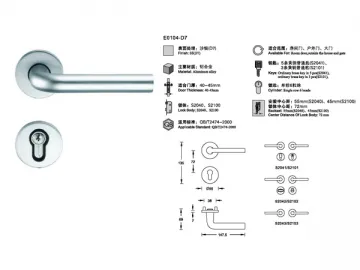

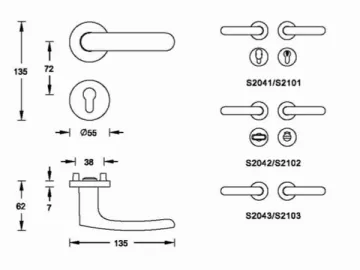

E0104-D7 Aluminum Alloy Door Lock

E0104-D7 Aluminum Alloy Door Lock

-

E0512-D7 Aluminum Alloy Door Lock

E0512-D7 Aluminum Alloy Door Lock

-

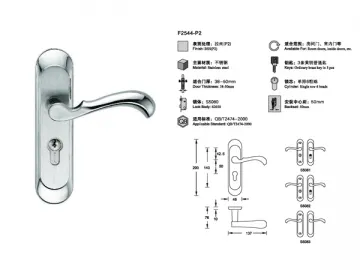

F2544-P2 Stainless Steel Door Lock

F2544-P2 Stainless Steel Door Lock

-

K6167 Cabinet Handle

K6167 Cabinet Handle

-

E0112-D7 Aluminum Alloy Door Lock

E0112-D7 Aluminum Alloy Door Lock