Flexo Printing Machine

Flexo Printing Machine

Our flexo printing machinesupports the instant curing after printing. One 6-color printing process could be done after theprinting media completes a circle around the machine. The result can bewonderful, no matter which kind of the printing is, color-registration orink-trapping.

1. Our printer has the cam type flexoprinting wheel and powerful servo motor. It can be used in the high-speedprinting production line. Its well-prepared configuration can meet the printingrequirements of various soft tube containers.

2. The flexo printingmachine has compact inner structure. It has six pairs of the flexo printing head and UV curinghead.

3. The corollary equipment we provide includes the touch-screen control system,automatic printing media feeding and unscrambling systems, flame processor,fast and slow mechanical synchronous transfer system, the full vacuumadsorption fixer.For your information, the automatic printing media feeding and unscramblingsystems can be customized.

Technical Parameters

| Printing product Size (Diameter x Length) | (Ø 13 mm - Ø 50mm) x ( Ø 20mm- Ø 230mm) |

| Maximum printing Area | 160mm x 170mm |

| Maximum Running Speed | 90pcs/min |

| UV lamp Power | 2.4kw each |

| Power Requirement | 380V 3phase 50Hz/60Hz |

| Compressed Air Pressure Requirement | 5-7 bar |

| Power Consumption | 27kw |

| Machine Dimension (Lx W x H) | 4300mm x 3300mm x 2428mm |

| Weight | 3000kg |

Links:https://www.globefindpro.com/products/55977.html

-

4-Color Offset Printing Machine with Varnishing

4-Color Offset Printing Machine with Varnishing

-

CA-1028 One Color Screen Printing Machine

CA-1028 One Color Screen Printing Machine

-

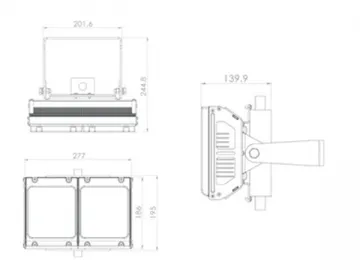

60W-80W LED Flood Light

60W-80W LED Flood Light

-

Clutch Release Bearing

Clutch Release Bearing

-

1-Color Pad Printing Machine

1-Color Pad Printing Machine

-

Automatic 2-Color Offset Printing Machine

Automatic 2-Color Offset Printing Machine

-

3-Color Pad Print Printing Machine

3-Color Pad Print Printing Machine

-

Round and Flat UV Curing Machine

Round and Flat UV Curing Machine

-

Engine Spark Plug

Engine Spark Plug

-

LED Tunnel Light

LED Tunnel Light

-

Multifunction Plastic Screen Printing Machine

Multifunction Plastic Screen Printing Machine

-

Low Metallic Brake Pad

Low Metallic Brake Pad