White Fused Alumina

WhiteFused Alumina

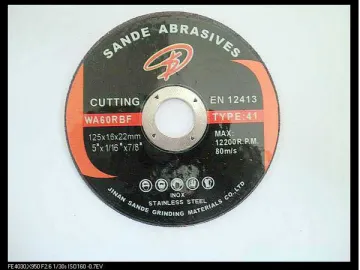

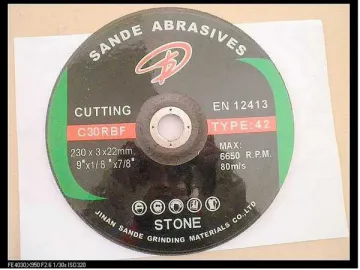

White fused aluminaconsist of high grade aluminum that is processed through an electric furnace athigh temperatures of up to 2,000 degrees centigrade. Also,it undergoes processing procedures such as ball mill crushing, magnetic ironseparation, and screening. The resulting product retains superb purityand is extremely resilient to deformation as well as acids and alkalis. Itcomes in white color and is grainy, with high Al2O3 content.In contrast with brown fused alumina, thewhite version possesses higher levels of hardness .

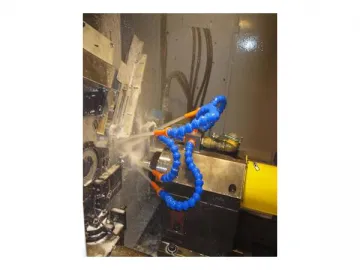

Apart from being utilized for the grinding of high carbon steel, high speedsteel and chilled steel, these tools can be applied as polishers, catalystcarriers, special ceramics, refractory materials, as well as spraying andcoating mediums. The fused alumina canenable high rate processing without affecting the color of the processingcases. Infused with a small quantity ofiron oxide, it is also ideal for sandblasting in non-ferrous procedures.

Specifications

| White Fused Alumina (WFA) Products | ||||

| Chemical Compositions | Physical Properties | |||

| Items | Value of Specification (%) | Items | Property | |

| Al2O3 | 99.55min. | Color | White | |

| SiO2 | 0.04max. | Bulk Density | 1.75-1.95g/ cm³ (function(){return ns_c({'fm':'alzd','tab':'zd','is_n_fld':'bestanswer'});})(); | |

| Na2O | 0.22max. | True Density | 3.95-3.97g/ cm³ | |

| Fe2O3 | 0.04max. | Hardness | Morse Hardness | 9 |

| Micro Hardness | 21600-22600kg/mm³ | |||

| CaO | 0.01max. | Content of Magnetic Substance | 0.0021%max. | |

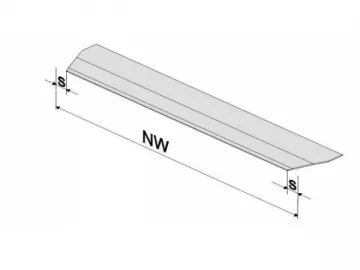

| Grains Types and Grades | |||

| Usage | For Vitrified Wheels | For Resinoid Bond | For Coated Abrasives |

| Type & Grade | WA | WA-B | WA-P1 |

| Grit No. | 12#--80#, 90#--150#, 180#--240# | ||

| Grain Size | 0-1mm, 1-3mm, 3-5mm, 5-8mm, 8-12mm | ||

| Available Grain No. | 180#-0, 200#-0, 320#-0 | ||

| Physical Chemical Performance Index | |||||

| Symbol | Range of the Grain | Chemical Composition(%,by weight) | True Density | Shape of the Grain | |

| WA | F12~80 | ≥ 98.50 | ≤ 0.40 | ≥ 3.90 | Blocky |

| F90~150 | ≥ 98.00 | ≤ 0.40 | |||

| F180~220 | ≥ 98.00 | ≤ 0.40 | |||

| F230~400 | ≥ 97.50 | ≤ 0.50 | |||

| F500~1200 | ≥ 97.00 | ≤ 0.60 | |||

| WA-B | F12~80 | ≥ 99.00 | ≤ 0.40 | ≥ 3.90 | Blocky |

| F90~150 | ≥ 98.50 | ≤ 0.40 | |||

| F180~220 | ≥ 98.00 | ≤ 0.40 | |||

| F230~600 | ≥ 97.50 | ≤ 0.50 | |||

| WA-P1 | F16~80 | ≥ 99.00 | ≤ 0.40 | ≥ 3.90 | Needle Shape |

| F100~150 | ≥ 98.50 | ≤ 0.40 | |||

| F180~400 | ≥ 98.00 | ≤ 0.50 | |||

| F500~1200 | ≥ 97.50 | ≤ 0.60 | |||

| Note: Special requirements on chemical compositions can be satisfied through further discussion. | |||||

With outstandingself-sharpening and grinding capabilities, this medium can be utilized for theprecision casting of superb refractory materials. Our product consists of the series WA, WA-Band WA-P1. The WA series is suitable forvitrified abrasive tools while our WA-B is targeted at resinoid bond abrasive tools and the WA-P1specifically designed for coating abrasive tools. Each series of white fused alumina contains varying granularspecifications. The finest size for ourWA series is F1200, or 20μm. As a ruleof thumb,the finer the size, the Al2O3 content is lower, and the hardness is lower accordingly. Clientsshould make informed purchases in accordance with their actual needs. It you have any inquiries regarding ourproducts or services, please feel free to contact us.

Links:https://www.globefindpro.com/products/56009.html