FT7 Cylinder Boring Machine

FT7Cylinder Boring Machine

,1,1:

4-Point Automatic Centering System

Quick Clamping Device

Inline Block

Main Control Board

,2,2:

Spindle Φ38mm (Φ39mm-Φ52mm) & Boring Cutters

Spindle Φ50mm (Φ51mm-Φ82mm) & Boring Cutters

Spindle Φ80mm (Φ81mm-Φ145mm) & Boring Cutters

Spindle Φ120mm (Φ121mm-Φ180mm) & Boring Cutters

Parallel Support A (60×70×610mm)

Parallel Support B (70×100×550mm)

30°45°V 30° and 45°V-fixture & Block Handler

FT7 cylinder boring machine is our latest machine developed in this year. It isdesigned to repair cylinder of automobile, motorcycle and tractor, and thecylinder diameter should between 39mm and 180mm. The maximum boring depth is400mm, and the spindle feed speed is 0.42-0.8mm/s. In addition, there are 3motors existing in this machine. The main motor is used to move the spindle tothe top of the floating table, the self-centering motor is responsible for the4-point automatic centering system, and a separated motor is applied forspindle feed.

Technical Parameters

| Model | FT7 |

| Range of Boring Diameter (mm) | 39-180 |

| Max. Boring Depth (mm) | 400 |

| Max. Longitudinal Travel of Spindle (mm) | 1058 |

| Max. Cross Travel of Spindle (mm) | 58 |

| Spindle Rotation Speed (rpm) | 50-1000 |

| Spindle Feed Speed (mm/s) | 0.42-0.80 |

| Spindle Move Speed (mm/s) | 5-16 |

| Main Motor Power (kW) | 1.1 |

| Spindle Feed Motor Power (kW) | 0.4 |

| Self-centering Motor Power (kW) | 0.15 |

| Pneumatic Pressure (pa) | 0.6<P<0.8 |

| Wheelhead Feed per Round (mm) | 0.5 |

| Wheelhead Feed per Grad (mm) | 0.005 |

| Overall Size (mm) | 1600x950x2095 |

| Net/Gross Weight (kg) | 1500/1800 |

Features

1. 4-point automatic centeringsystem is adopted by this cylinder boring machine, thus the processing is veryprecise with high speed.

2. This product is equipped with power assistant device which is beneficial tomove the spindle to the top of the floating table.

3. The air floating V-fixture allows the machine to work with 45° and 60° V cylinder.

Links:https://www.globefindpro.com/products/56082.html

-

CAMDA Gas Generator

CAMDA Gas Generator

-

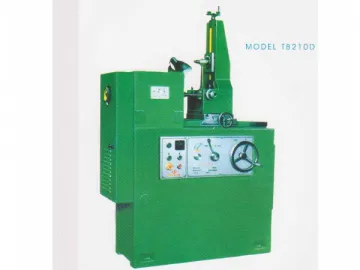

T80 Series Cylinder Boring Machine

T80 Series Cylinder Boring Machine

-

Silent Diesel Generator Set

Silent Diesel Generator Set

-

Universal Cylinder Head Workstation

Universal Cylinder Head Workstation

-

Car Rearview Monitor with 7-inch TFT LCD Display

Car Rearview Monitor with 7-inch TFT LCD Display

-

Connecting Rod Bushing Boring Machine

Connecting Rod Bushing Boring Machine

-

Urea Phosphate

Urea Phosphate

-

C9350 Brake Lathe

C9350 Brake Lathe

-

Permanent Ferrite Magnet

Permanent Ferrite Magnet

-

T170S Vertical Fine Boring Machine

T170S Vertical Fine Boring Machine

-

Valve Seat Grinding Machine

Valve Seat Grinding Machine

-

C9335 Brake Drum and Disc Lathe

C9335 Brake Drum and Disc Lathe