CAMDA Gas Generator

CAMDA Gas Generator

Our CAMDA natural gas generator or biogas generator is composed of an engine developed and produced together by Cummins and CAMDA. Because of the durable engine body, the gas engine enjoys a long service life up to 30 years. Over 90% spare parts are made in Cummins factory, so that the user has easy access to high quality accessories. In addition, the equipment is manufactured in compliance with CE, ISO9001:2008, ISO14001:2004 and OHSAS18001:2007 standards, so that the user can feel secure in using it.

Specifications

Model Item | KDGH 25-G | KDGH 50-G | KDGH 80-G | KDGH 120-G | KDGH 200-G | KDGH250-G | KDGH 500-G |

Electrical Output (kW) | 25 | 50 | 80 | 120 | 200 | 250 | 500 |

Generator Insulation Class | H | H | H | H | H | H | H |

Frequency | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz |

Engine Model | HG4B | HG6B | HGN14 | HGN14 | HGK19 | HGK19 | HGK38 |

Cylinders | 4 | 6 | 6 | 6 | 6 | 6 | 12 |

Bore X Stroke (mm) | 102*120 | 102*120 | 140*152 | 140*152 | 159*159 | 159*159 | 159*159 |

Inspiration | Naturally | Turbo charging | |||||

Displacement (L) | 3.92 | 5.88 | 14 | 14 | 18.9 | 18.9 | 37.8 |

Compression Ratio | 11.5:1 | 11.5:1 | 11.5:1 | 11.5:1 | 11:1 | 11:1 | 11:1 |

Fuel | Natural Gas / Biogas | ||||||

Gas Consumption (MJ/kW·h ) | 11.2 | 11.0 | 10.8 | 10.8 | 10.4 | 10.4 | 10.2 |

Oil Recommended | Gas Engine Oil 15W-40, recommended brand-TOTAL | ||||||

Oil Consumption | ≤0.5g/kW.h | ≤1.0g/kW.h | |||||

Exhaust Temperature | ≤ 680 ℃ | ≤ 600 ℃ | |||||

Net Weight ( kg ) | 900 | 1100 | 1700 | 2800 | 3380 | 3580 | 6080 |

Dimension (mm) | 1800*710*1350 | 2300 *820 *1400 | 2450 *820 *1550 | 3150 *1000 *1500 | 3470 *1230 *2300 | 3400 *1300 *1850 | 4250 *1700 *2185 |

Features

1. The gas generator can operate 20000 to 25000 hours till overhauled.

2. The cogeneration efficiency is more than 85%, which is about 10% higher than other Chinese brands.

3. Each cylinder is designed with four air valves, providing adequate intake and exhaust to achieve maximum power output.

4. The electronically controlled air-gas mixer offers optimal air-fuel ratio, improves thermal efficiency and reduces emissions of nitrogen oxides. The unique air-fuel ratio regulation system is suitable for the gas of 30-90% methane concentration.

5. The ignition system imported from U.S. Altronic ensures high-precision ignition control, thus enhancing the durability and stability of genset.

6. The fully automatic intelligent control system allows for easy operation and automatic inspection for running faults.

Working Conditions

Ambient temperature : 0℃~ 40℃, special design is required below 0℃ (antifreeze or hot water is needed below -20℃)

Relative humidity: <90% (20℃)

Altitude: ≤1000m

Standard conditions: Atmospheric Pressure: 100kPa, Ambient Temp: 20℃, Relative Humidity: 30%

Fuel Requirements

Applicable gas: Natural Gas, Biogas

Gas requirements within one meter before pressure regulating valve:

Gas temperature: ≤40℃

For natural gas:

Natural gas low heat value: ≥ 8000kcal/Nm3 (31MJ/Nm3)

Natural gas inletting pressure: 2~10kPa (more valves shall be needed if pressure is higher)

For biogas:

Biogas low heat value: ≥5000kcal/Nm3 (21MJ/Nm3 ) (Heat value<5500kcal/Nm3, it will lower the power efficiency)

Biogas inletting pressure: 0kPa (more valves shall be needed if pressure is higher)

CH4 volume content: ≥30%, change ratio: ≤2% ∕ min.

Gas relative humidity: ≤ 100%

O2 content: ≤ 2% vol

H2 content: ≤ 12% vol

H2S content: ≤200mg/Nm3

NH3 content: ≤20mg/Nm3

Solid particle content: ≤10 mg/Nm³

Solid particle size: ≤ 5μm

Links:https://www.globefindpro.com/products/56086.html

-

T80 Series Cylinder Boring Machine

T80 Series Cylinder Boring Machine

-

Silent Diesel Generator Set

Silent Diesel Generator Set

-

Universal Cylinder Head Workstation

Universal Cylinder Head Workstation

-

Car Rearview Monitor with 7-inch TFT LCD Display

Car Rearview Monitor with 7-inch TFT LCD Display

-

Connecting Rod Bushing Boring Machine

Connecting Rod Bushing Boring Machine

-

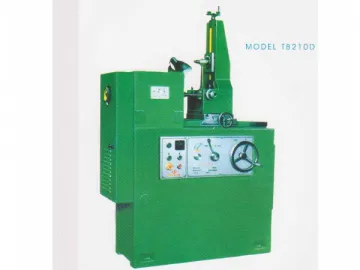

Valve Grinding Machine

Valve Grinding Machine

-

FT7 Cylinder Boring Machine

FT7 Cylinder Boring Machine

-

Urea Phosphate

Urea Phosphate

-

C9350 Brake Lathe

C9350 Brake Lathe

-

Permanent Ferrite Magnet

Permanent Ferrite Magnet

-

T170S Vertical Fine Boring Machine

T170S Vertical Fine Boring Machine

-

Valve Seat Grinding Machine

Valve Seat Grinding Machine