EHR Corrosion Resistant Slurry Pump

EHR Corrosion Resistant Slurry Pump

EHR corrosion resistant slurry pump adopts rubber materials as over current components, which can be applied to carrying fine particles and corrosive slurry. Besides, EHR and EHM type pump are generic in frame plate, cover plate, transmission parts and so on.

EHR Series Performance Chart

| Model | Allowable Max Power P( Kw ) | Clear Water Performance | Impeller | |||||

| Capacity Q | Head H(m) | Rotate Speed n(r/min) | Top Efficiency η% | NPSH(m) | Impeller Diameter D(mm) | |||

| M 3 /h | I/s | |||||||

| EHR-1B | 15 | 10.8-25.2 | 3-7 | 7-52 | 1400-3400 | 35 | ||

| EHR-1.5B | 15 | 25.2-54 | 7-15 | 5.5-41 | 1000-2600 | 50 | 2.5-5 | 178 |

| EHR-2C | 30 | 36-75.6 | 10-21 | 13-39 | 1300-2100 | 2-4 | 213 | |

| EHR-3C | 30 | 79.2-187.2 | 22-52 | 5-34.5 | 800-1800 | 59 | 3-5 | 245 |

| EHR-3D | 60 | |||||||

| EHR-4D | 60 | 144-313 | 40-87 | 12-45 | 800-1350 | 65 | 3-5 | 365 |

| EHR-4E | 120 | |||||||

| EHR-6E | 120 | 324-713 | 90-198 | 7-49 | 400-1000 | 65 | 5-10 | 510 |

| EHR-6R | 300 | |||||||

| EHR-8ST | 560 | 540-1188 | 150-330 | 12-50 | 400-750 | 75 | 4-12 | 686 |

| EHR-10ST | 560 | 720-1620 | 200-450 | 7-45 | 300-650 | 80 | 2.5-7.5 | 762 |

| EHR-12ST | 560 | 1156-2520 | 321-700 | 13-14 | 300-500 | 79 | 3-8 | 965 |

| EHR-14TU | 1200 | 1379-3060 | 383-850 | 11-63 | 250-550 | 79 | 4-10 | 1067 |

| Note: 1. Quantity range recommend: 50% Q′≤Q≤110%Q′(Q′ appropriate to capacity at highest efficiency point) 2. NPSH: appropriate to point Q recommended at highest speed. | ||||||||

Advantages

1. Our corrosion resistant slurry pump is heavy duty product, wet parts of which are mainly composed of natural rubber. It is characterized by great wear resistance, outstanding corrosion resistance and long service life.

2. It is flexible to select over current component materials. Except for natural rubber, customers can also choose other synthetic adhesive for special conditions according to their requirement.

3. With double casing structure, our product is easy to replace the components and dismantle as well as cheap to maintain.

Sphere of Applications

Our corrosion resistance slurry pump is cantilevered centrifugal, suitable for conveying abrasive or corrosive slurry, extensively applied to metallurgy, mine, petroleum, chemicals, coal, electric power, transportation, river dredging, building materials, building materials, municipal works and so on.

Note

1. The drive type can be classified into direct connection, V-belt drive, gear box reducer, fluid coupling drive, variable frequency drive and more.

2. The discharge direction of our corrosion resistance slurry pump is oriented in any direction of the eight angles in accordance with the requirement in the specific working conditions. The discharge is settled upside usually if there is no requirement.

3. Three seal types are available, including packing seal, expeller seal and mechanical seal. The expeller seal is often used. Customers can also raise their requirement before placing the order.

Model Explanation

E: Excellence

H: Heavy duty slurry pump

R: Rubber lined

4: Discharge Size (inch)

D: Frame Type

Structural Diagram

Series EHR structural drawing:

1.Frame 6.Cover plate liner

2.Bearing assembly 7.Throatbush

3.Frame plate 8.Cover plate

4.Stuffing box 9.Impeller

5.Frame plate liner 10.Adjusting bolt

Note: this is the basic structural drawing.

There is a little difference up to the varied

discharge sizes.

Related Names

Rubber Lined Slurry Pump | Centrifugal Mud Pump | Lobe Pump

Links:https://www.globefindpro.com/products/56500.html

-

EHM, EGM Heavy Duty Slurry Pump

EHM, EGM Heavy Duty Slurry Pump

-

HT3 Dual Band Handheld Transceiver

HT3 Dual Band Handheld Transceiver

-

AT-5189 Single Band Vehicle Radio /Mobile Radio

AT-5189 Single Band Vehicle Radio /Mobile Radio

-

Dual Band Vehicle Radio/Mobile Radio

Dual Band Vehicle Radio/Mobile Radio

-

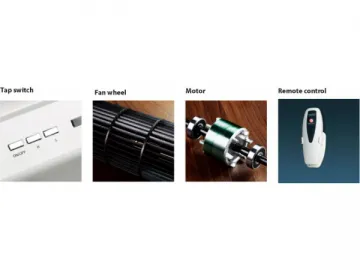

5G Heating Air Curtain

5G Heating Air Curtain

-

Compact Air Curtain

Compact Air Curtain

-

AT608M Citizen Band Radio

AT608M Citizen Band Radio

-

HT2 Dual Band Handheld Transceiver

HT2 Dual Band Handheld Transceiver

-

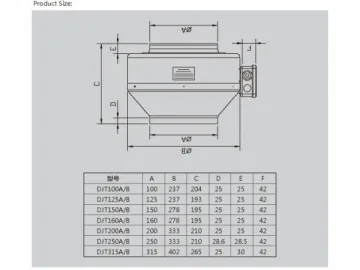

Circular Duct Ventilation Fan

Circular Duct Ventilation Fan

-

3G Warm Cold Wind Air Curtain

3G Warm Cold Wind Air Curtain

-

Titan 3 Super Thin Air Curtain

Titan 3 Super Thin Air Curtain

-

Large Wind Air Curtain

Large Wind Air Curtain