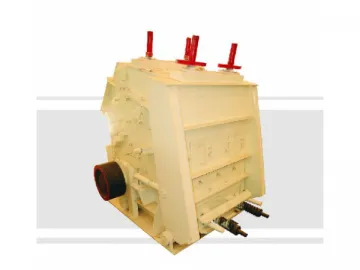

Impact Crusher

Impact Crusher

The impact crusher has advantages thatit has large reduction ratio, usually between 10% and 20%, or higher up to50%-60%. Also, it has simplified crushing processes, simplified structure andas a result it is easy for use and maintenance. Additionally, the crushingequipment has higher crushing capacity and smaller size as compared with othertypes of crushers. The crushed materials come in cubic shape and the particlesize is adjustable to suit customers’ varied demands.

Our impact crusher is widely used for coarse, medium and fine crushing ofmaterials such as coal, asbestos, graphite, limestone, dolomite, shale,sandstone, and rock salt etc. So, it is commonly used in building material,chemical, and coal mine industries.

TechnicalSpecifications of the Impact Crusher

| Model | Rotor size (mm) | Max. feeding material size (mm) | Crushed material size (mm) | Power (kw ) | Production capacity (t/h) | Weight (kg) |

| PF-0807 | Ф850×700 | 300 | 85%≤25 | 30 | 10-25 | 3500 |

| PF-1007 | Ф1000×700 | 300 | 85%≤25 | 37 | 15-30 | 6500 |

| PF-1010 | Ф1000×1050 | 350 | 85%≤25 | 55-75 | 50-80 | 12100 |

| PF-1210 | Ф1250×1050 | 350 | 85%≤25 | 110-132 | 70-120 | 14000 |

| PF-1214 | Ф1250×1400 | 400 | 85%≤25 | 132-160 | 130-180 | 18500 |

| PF-1315 | Ф1300×1500 | 500 | 85%≤25 | 160-200 | 180-260 | 23500 |

| PF-1320 | Ф1320×2000 | 500 | 85%≤25 | 300-350 | 300-350 | 26500 |

Working Principle of the Impact Crusher

An impact crusher is designed with arotor driven by an electric motor, hard alloy hammers on the rotor, and impactplates, etc. as the main functional parts to crush materials. The motor drivesthe rotor to rotate in a very high speed. Thus, when materials are fed into theimpact crusher, they are coarsely crushed by the strong impact force betweenthe materials and the hammers on the rotating rotor. Then, the coarsely crushedmaterials are thrown to the first impact plate to be crushed again, andmeanwhile, they are further crushed by the force caused by the collision amongthe materials. In addition, some materials, after crushed by the first impactplate, pass through the gap between the first impact plate and the rotor and enterinto the secondary crushing chamber to be crushed by the second impact plate.Finally, the repeated crushed materials are discharged from the discharginghole at the bottom of the impact crusher.

Note: The impact crusher is ideal forcrushing hard rocks, and when it is used for crushing granite, the particlesize of 90% crushed material is no more than 40mm.

Links:https://www.globefindpro.com/products/56547.html

-

Heavy Duty /High Head Slurry Pump

Heavy Duty /High Head Slurry Pump

-

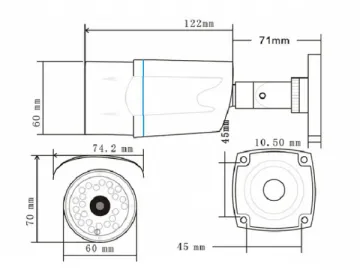

IP888PB IR IP CCTV Camera

IP888PB IR IP CCTV Camera

-

Four Roller Briquette Machine

Four Roller Briquette Machine

-

HT9 Single Band Handheld Transceiver

HT9 Single Band Handheld Transceiver

-

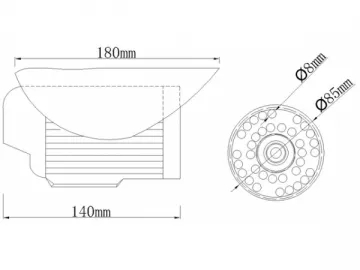

8806HRC 600TVL CCTV Camera

8806HRC 600TVL CCTV Camera

-

Slurry Pump Spare Parts

Slurry Pump Spare Parts

-

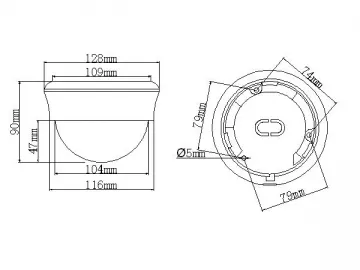

3589B High Resolution CCTV Camera

3589B High Resolution CCTV Camera

-

689AE High Resolution CCTV Camera

689AE High Resolution CCTV Camera

-

Cabinet Heat Pump Water Heater

Cabinet Heat Pump Water Heater

-

AT-108 Citizen Band Radio

AT-108 Citizen Band Radio

-

Integrated Heat Pump Water Heater

Integrated Heat Pump Water Heater

-

Cycle Air Source Heat Pump

Cycle Air Source Heat Pump