Jaw Crusher

Jaw Crusher

The jaw crusher has a deep crushing chamberwithout dead area, so it offers improved feeding capacity and crushingcapacity. Designed with a gasket type discharging hole adjustment device, itcan easily achieve adjustment on discharging hole size, thus improving theequipment flexibility and meeting end users’ varied demands as well. With reliable and safe lubrication system andeasy changing of equipment parts, the jaw crusher requires low maintenance. In addition, it featureslarge reduction ratio, uniform end product particle size, low operation noise,low dust generation, simple structure, and low energy consumption as well.

Due to above advantages and wide selection of models, our jaw crushers arewidely used for medium crushing of mineral ores and blocks in mining,metallurgy, road construction, railway construction, water conservancy andchemical industries. They are commonly used as the ancillary equipment in sandproduction line and stone crushing equipment.

Technical Specifications of the Jaw Crusher

| Model | Max. Feeding Size (mm) | Discharging Size (mm) | Spindle speed (r/min) | Motor power (kw ) | Crushing Capacity (t/h) | Dimensions (mm) | Weight (kg) |

| PE150×250 | 125 | 10-40 | 285 | 5.5 | 1-3 | 922×745×933 | 750 |

| PE200×300 | 165 | 15-50 | 265 | 7.5 | 2-8 | 1056×1100×1120 | 1100 |

| PE250×400 | 210 | 20-60 | 300 | 15 | 5-20 | 1108×1142×1392 | 2900 |

| PE400×600 | 340 | 40-90 | 280 | 30 | 25-64 | 1700×1732×1653 | 6900 |

| PE500×750 | 425 | 50-100 | 275 | 55 | 34-68 | 2050×1860×2145 | 10500 |

| PE600×900 | 480 | 65-160 | 250 | 75 | 56-192 | 2792×2168×2250 | 17500 |

| PE750×1060 | 630 | 80-140 | 250 | 90 | 110-242 | 4180×2560×3070 | 27000 |

| PE900×1200 | 750 | 100-200 | 250 | 110 | 158-256 | 5200×2900×3500 | 50000 |

| PEX150×750 | 125 | 10-40 | 300 | 15 | 8-35 | 1220×1480×1180 | 3300 |

| PEX250×1000 | 210 | 15-50 | 300 | 30 | 15-50 | 1580×1992×1380 | 7100 |

| PEX250×1200 | 210 | 15-50 | 300 | 45 | 20-60 | 1730×2192×1380 | 8700 |

| PEX300×1300 | 250 | 20-90 | 300 | 75 | 20-90 | 1930×2400×1747 | 11600 |

How does the Jaw Crusher Work?

A jaw crusher is designed with a motor for belt and belt wheel driving,eccentric shaft, fixed jaw, movable jaw, toggle plate, and more. The eccentricshaft allows the movable jaw to move up and down. When the movable jaw movesforward, the intersection angle between the movable jaw and toggle plate isenlarged and the movable jaw moves toward to the fixed jaw. Thus, raw materialsfed into the crushing chamber between the two jaws are crushed. When themovable jaw moves backward, the intersection angle between the movable jaw andtoggle plate is reduced, and the movable jaw departs from the fixed one. Thus,the crushed materials can be discharged from the outlet of the crushingchamber. With the continuous working of the motor, the jaw crusher works continuously,thus achieving batch production.

Equipment Construction

The jaw crusher is primarily composed of fixed parts, rotating parts,safety devices, and adjustment devices.

The fixed parts mainly refer to the machine frame. We can offer jaw crusherswith either medium carbon steel cast frame or medium carbon steel plate weldedframe. The welded frame comes with additional reinforcing bars based on castframe and has passed our rigorous quality controls and specific technicalrequirements. Hence, our jaw crusher with welded frame has the same performanceas that with cast frame. In order to prevent the severe abrasion of side panelsof the frame, protective panels are available on the right and left side of thecrushing chamber and are convenient for replacement. This design extends theservice life of the crusher frame.

The rotating parts of the jaw crusher include the movable jaw, eccentric shaft,bearing, belt wheel, and so on. The movable jaw consists of a jaw bracket and amoving jaw plate, and its jaw bracket is made of 35# cast steel and is givenquenching and tempering to ensure superior mechanical performances. In order toimprove crushing effect, the jaw plate surface is designed with teeth and ismade of ZGMn13which features high hardness and good wearing resistance. The eccentric shaft made of 45# steel isgiven quenching and tempering as well. The jaw crusher utilizes double row selfaligning spherical roller bearing which offers fine adjustment function, largebearing capacity and is durable.

Links:https://www.globefindpro.com/products/56565.html

-

6806C 600TVL CCTV Camera

6806C 600TVL CCTV Camera

-

AT-628G Single Band Hand Held Transceiver

AT-628G Single Band Hand Held Transceiver

-

H10 Single Band Handheld Transceiver

H10 Single Band Handheld Transceiver

-

High Efficiency Slurry Pump

High Efficiency Slurry Pump

-

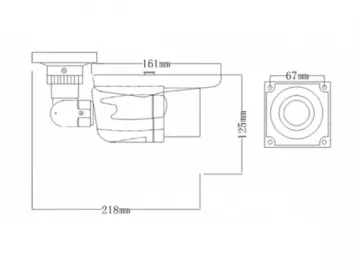

8789PB High Resolution CCTV Camera

8789PB High Resolution CCTV Camera

-

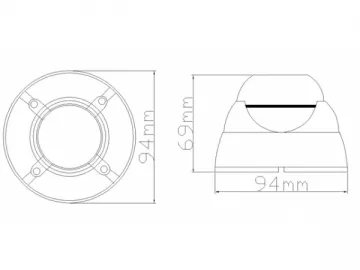

84H-10B Mini PTZ Dome Camera

84H-10B Mini PTZ Dome Camera

-

AT-938G Single Band Hand Held Transceiver

AT-938G Single Band Hand Held Transceiver

-

AT-3218G Single Band Hand Held Transceiver

AT-3218G Single Band Hand Held Transceiver

-

889PB High Resolution CCTV Camera

889PB High Resolution CCTV Camera

-

AT-898 Single Band Hand Held Transceiver

AT-898 Single Band Hand Held Transceiver

-

AT-3319G Single Band Hand Held Transceiver

AT-3319G Single Band Hand Held Transceiver

-

689BM High Resolution CCTV Camera

689BM High Resolution CCTV Camera