Roller Grinder

Roller Grinder

The roller grinder is a combination ofa grinding machine and a mixing machine. It can be used to grind a mixture andthen mix the material once more, so as to ensure the forming quality of finalproducts such as baking-free brick, autoclaved bricks, refractory material,ceramics and variety of building materials. Our roller grinder features dust-freeoperation, high grinding and mixing efficiency, and very good material mixingeffect. Meanwhile, it is energy efficient, convenient for installation and easyfor maintenance.

The roller grinder can be used to coarsely crush materials by taking advantageof its grinding disk and rollers. The materials are fed through the centralpart of the disc. Due to the push of a scraper blade and the centrifugal forcecaused by disc’s rotation, the materials are delivered to the area under theroller and undergo multiple times of pulverizing. Finally, qualified particleswill pass through the screen mesh surrounding the disc and be collected, whileunqualified ones are sent back to be crushed again. Our roller grinder is idealfor grinding medium hardness materials such as silica and clay.

Technical Parameters of the RollerGrinder

| Model | S110 | S112 | S114 | S116 | S118 | S120 | S125 |

| Disc Diameter (mm) | Φ 1000 | Φ 1220 | Φ 1440 | Φ 1600 | Φ 1800 | Φ 2000 | Φ 2500 |

| Feeding Quantity (Kg) | 110 | 150 | 200 | 450 | 650 | 900 | 1700 |

| Mixing Time (min) | 3-8 | 3-5 | 3-5 | 2 . 5 | 3-5 | 2-5 | 2-5 |

| Grinding Capacity (t/h) | 1.5-2.5 | 1.5-3.0 | 4-5 | 10 | 13-15 | 20 | 40 |

| Main Shaft Speed (r/min) | 41 | 41/27 | 24 | 40 | 36.1 | 35 | 30 |

| Roller Size (mm) | 666 × 127 | 670 × 140 | 700 × 180 | 670 × 210 | 750 × 230 | 800 × 260 | 1000 × 320 |

| Rolling Pressure (N) | 0-1078 | 0-1200 | 0-2000 | 0-4116 | 0-7000 | 0-8000 | 0-12000 |

| Power (Kw) | 4 | 4 | 7 . 5 | 20 | 22 | 37 | 75 |

| Weight (kg) | 900 | 1337 | 2000 | 4000 | 4720 | 5500 | 9000 |

Links:https://www.globefindpro.com/products/56579.html

-

Belt Conveyor

Belt Conveyor

-

IP8788P IR IP CCTV Camera

IP8788P IR IP CCTV Camera

-

Force Feeding Briquette Machine

Force Feeding Briquette Machine

-

Dual Shaft Mixer

Dual Shaft Mixer

-

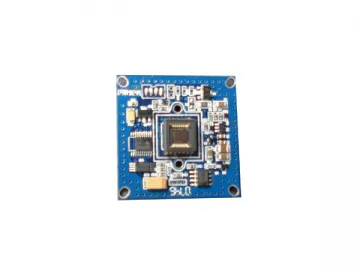

602 Sharp Board CCTV Camera

602 Sharp Board CCTV Camera

-

5839C High Resolution CCTV Camera

5839C High Resolution CCTV Camera

-

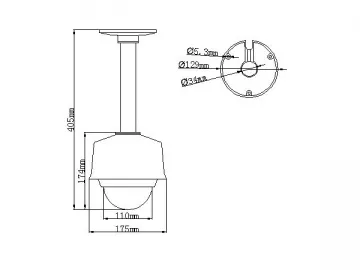

84H-10D Mini PTZ Dome Camera

84H-10D Mini PTZ Dome Camera

-

807 Sony Board CCTV Camera

807 Sony Board CCTV Camera

-

AT-5289 Citizen Band Radio

AT-5289 Citizen Band Radio

-

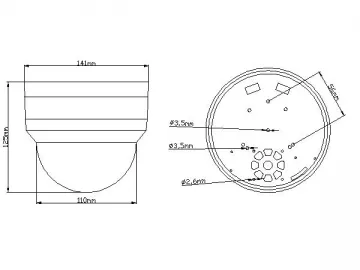

84H-10 Mini PTZ Dome Camera

84H-10 Mini PTZ Dome Camera

-

AT601T Selective Band Mobile Phone Repeater / Signal Booster

AT601T Selective Band Mobile Phone Repeater / Signal Booster

-

5806C 600TVL CCTV Camera

5806C 600TVL CCTV Camera