Belt Conveyor

Belt Conveyor

The belt conveyor is also called arubber belt conveyor and features large conveying capacity. With simplestructure and standardized parts, it is convenient for maintenance. It can workindependently, and can also work in combination with other conveying equipmentfor horizontal or inclined material conveying. It is widely used in mining,metallurgy, coal and more industries.

The belt conveyor is mainly composed of a rubber belt, conveyor frame, beltroller, and motor. The motor functions to drive the belt roller through areducer, so the roller rotates continuously. Due to the friction between theroller and the belt, the rubber belt will also work continuously and thusfunctions to convey materials.

Technical Parameters of the Belt Conveyor

| Model | Belt Width (mm) | Belt Speed (m/s) | Inclination Angle ( ° ) | Conveying Capacity (t/h) | Motor Power (KW) |

| TD75-B500 | 500 | 0.8-2 | ≤ 18 | 40 — 80 | 1.5 — 30 |

| TD75-B650 | 650 | 0.8-1.6 | ≤ 18 | 40 — 243 | 2.2 — 40 |

| TD75-B800 | 800 | 1-2 | ≤ 18 | 75 — 500 | 3 — 75 |

| TD75-B1000 | 1000 | 1-2 | ≤ 18 | 140 — 770 | 4 — 90 |

| TD75-B1200 | 1200 | 1-2.5 | ≤ 18 | 200 — 980 | 5.5 — 185 |

The belt conveyor is a piece ofcommonly used ancillary equipment in a sand production line or stone crushingscreening machine. We have over 20 years experience in design and manufacturebelt conveying equipment and related equipment as well, and we havesuccessfully developed stone crushing screening equipment and sand makingequipment with production capacity between 30t/h and 350t/h. We implement allproduction processes in accordance with ISO9001:2008 standard,and the product on this page is given 12 months warranty.

Links:https://www.globefindpro.com/products/56580.html

-

IP8788P IR IP CCTV Camera

IP8788P IR IP CCTV Camera

-

Force Feeding Briquette Machine

Force Feeding Briquette Machine

-

Dual Shaft Mixer

Dual Shaft Mixer

-

602 Sharp Board CCTV Camera

602 Sharp Board CCTV Camera

-

5839C High Resolution CCTV Camera

5839C High Resolution CCTV Camera

-

Wheel Sand Washing Machine

Wheel Sand Washing Machine

-

Roller Grinder

Roller Grinder

-

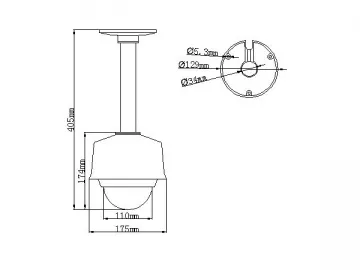

84H-10D Mini PTZ Dome Camera

84H-10D Mini PTZ Dome Camera

-

807 Sony Board CCTV Camera

807 Sony Board CCTV Camera

-

AT-5289 Citizen Band Radio

AT-5289 Citizen Band Radio

-

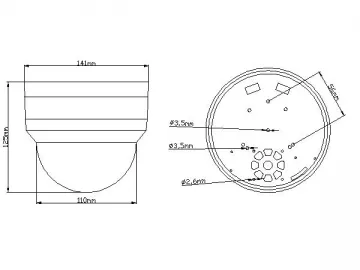

84H-10 Mini PTZ Dome Camera

84H-10 Mini PTZ Dome Camera

-

AT601T Selective Band Mobile Phone Repeater / Signal Booster

AT601T Selective Band Mobile Phone Repeater / Signal Booster