Hammer Crusher

Hammer Crusher

The hammercrusher has features like simple structure, high reduction ratio and high crushingcapacity, etc. Suitable for both dry and wet type crushing, the crusher iscommonly used for crushing medium hardness and brittle materials, and has foundwide range of applications in industries such as mining, cement, coal, metallurgy, building materials, roadconstruction, and more. The discharging material size is adjustable, so ourhammer crushers can satisfy users’ varied application demands.

Our hammer crusher is constituted of machine body, rotor, hammer, motor, screenplate and impact plate, etc. When materials are fed into the crushing chamber,they are crushed due to its impact with the hammer rotating in high speed.Then, the qualified particles will pass through the screen plate to bedischarged, and unqualified particles are sent back to be crushed again untilthey are pulverized to desired size.

Technical Parameters of the HammerCrusher

| Model | Rotor Size (Diameter × length) (mm) | Rotor Speed (r/min) | Feeding Size (mm) | Discharging Material Size (mm) | Motor power (KW) | Capacity (t/h) | Weight (kg) |

| PC400×300 | Φ400×300 | 1440 | ≤100 | ≤10 | 7.5 | 5-10 | 900 |

| PC600×400 | Φ600×400 | 960 | ≤100 | ≤15 | 18.5 | 10-20 | 1500 |

| PC800×600 | Φ800×600 | 970 | ≤120 | ≤15 | 45 | 18-24 | 2680 |

| PC1000×800 | Φ1000×800 | 990 | ≤200 | ≤15 | 110 | 30-50 | 5600 |

| PC1000×1000 | Φ1000×1000 | 990 | ≤200 | ≤15 | 132 | 30-60 | 8000 |

| PC1200×1200 | Φ1200×1200 | 750 | ≤250 | ≤20 | 180 | 90-110 | 19000 |

Note: Inorder to ensure crushing efficiency, the hammer crusher needs periodical checkon its hammer and lubrication system. If the hammer is seriously damaged,please change it timely.

Links:https://www.globefindpro.com/products/56587.html

-

83H-18A High Speed Dome Camera

83H-18A High Speed Dome Camera

-

82H-18A High Speed Dome Camera

82H-18A High Speed Dome Camera

-

86H-22 High Speed Dome Camera

86H-22 High Speed Dome Camera

-

Spiral Chute

Spiral Chute

-

Double Stage Crusher

Double Stage Crusher

-

81H-18A High Speed Dome Camera

81H-18A High Speed Dome Camera

-

Wheel Sand Washing Machine

Wheel Sand Washing Machine

-

5839C High Resolution CCTV Camera

5839C High Resolution CCTV Camera

-

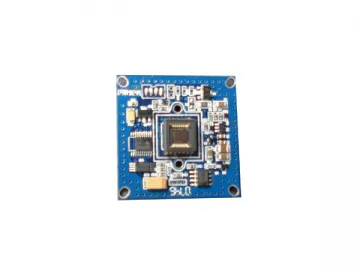

602 Sharp Board CCTV Camera

602 Sharp Board CCTV Camera

-

Dual Shaft Mixer

Dual Shaft Mixer

-

Force Feeding Briquette Machine

Force Feeding Briquette Machine

-

IP8788P IR IP CCTV Camera

IP8788P IR IP CCTV Camera