Spiral Chute

Spiral Chute

The spiral chute features easy controland installation, simple structure and operation, low cost, and stableoperation. It allows for feeding materials with wide density range, and offershigh concentration ratio, small land occupation area, and low waterconsumption. As a kind of gravity separating equipment, it requires no powersystem and hence is extraordinary energy efficient. Our spiral chute is designedfor separation of mineral ores with particle size between 0.02mm and 0.3mm, including iron ores, ilmenite, chromite,brasses, zirconite, rutile, monazite, xenotime, tungsten ore, tin ore,tantalum ore, niobium ore, and more mineral materials with different specificgravity.

Working Processes

Firstly, keep the spiral chute upright and fix it in a proper position usingsteel or wooden frames. Then, using sand pump to pump the ore slurry to the twofeeding holes at the top of the spiral chute, and meanwhile, add water into theslurry to adjust the slurry concentration. The slurry will flow downwardnaturally along with the spiral, and an inertial centrifugal force is generatedduring the process. Thus, the mineral ores and sand materials are separatedsuccessfully by the spiral chute due to their different specific gravity, grainsize and shape, etc. Finally, the ore concentrate flows into the specified orehopper, delivered via pipelines and collected. While sand materials areconveyed to the sand pond and discharged by sand pumps.

Technical Parameters of the Spiral Chute

| Model | LL-2000 | LL-1500 | LL-1200 | LL-900 | LL-600 |

| Diameter (mm) | 2000 | 1500 | 1200 | 900 | 600 |

| Spiral Pitch (mm) | 1200/1500 | 540/720 | 540/720/900 | 405/540/675 | 270/360/450 |

| Pitch Ratio | 0.6/0.75 | 0.45/0.6 /0.75 | 0.45/0.6 /0.75 | 0.45/0.6 /0.75 | 0.45/0.6 /0.75 |

| Spiral Slope (°) | 9 | 9 | 9 | 9 | 9 |

| Spiral quantity | 4 | 4 | 4 | 4 | 3 |

| Feeding Size (mm) | 0.04-2 | 0.02-2 | 0.03-0.3 | 0.03-0.3 | 0.02-0.2 |

| Feeding Material Concentration (%) | 25-55 | 25-55 | 25-55 | 25-55 | 25-55 |

| Capacity (t/h) | 12-30 | 6-12 | 4-6 | 2-3 | 0.8-12 |

| Dimension (mm) | 2100 ×2100 ×5600 | 1580 ×1580 ×5230 | 1360 ×1360 ×5230 | 1100 ×1100 ×4000 | 700 ×700 ×2600 |

| Weight (kg) | 2000 | 1100 | 600 | 400 | 150 |

Links:https://www.globefindpro.com/products/56592.html

-

Double Stage Crusher

Double Stage Crusher

-

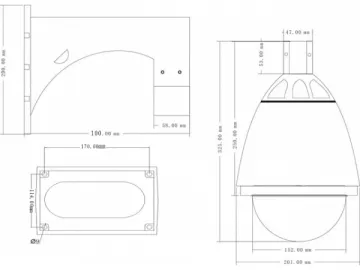

81H-18A High Speed Dome Camera

81H-18A High Speed Dome Camera

-

85H High Speed Dome Camera

85H High Speed Dome Camera

-

Spiral Sand Washing Machine

Spiral Sand Washing Machine

-

80H-18A High Speed Dome Camera

80H-18A High Speed Dome Camera

-

Auto Centering Vibration Screen

Auto Centering Vibration Screen

-

86H-22 High Speed Dome Camera

86H-22 High Speed Dome Camera

-

82H-18A High Speed Dome Camera

82H-18A High Speed Dome Camera

-

83H-18A High Speed Dome Camera

83H-18A High Speed Dome Camera

-

Hammer Crusher

Hammer Crusher

-

Wheel Sand Washing Machine

Wheel Sand Washing Machine

-

5839C High Resolution CCTV Camera

5839C High Resolution CCTV Camera