Double Stage Crusher

Double Stage Crusher

The double stage crusher is ideal forpulverizing coal gangue, shale, coal cinder, and other similar materials withhigh water content. Without a screen stencil at the bottom, the crushingequipment won’t be blocked while being used for crushing high water contentmaterials. It is able to finish the work of two hammer crushers, as its tworotors can work synchronously. One upper rotor and one lower rotor allow theequipment to offer double stage pulverizing, thus offering fine materialsfinally.

The high alloy content hammer of the double stage crusher has superior wearingresistance, which ensures long service life. Meanwhile, the hammer can berepeatedly utilized for material pulverizing as it can be removed andrepositioned. Designed with hydraulically opened machine housing, the crusheris convenient for maintenance.

Technical Parameters of the Double StageCrusher

| Model | SCP 600×400 | SCP 600x600 | SCP800×600 | SCP 900×800 | SCP 1000x800 |

| Feeding Size (mm) | ≤100 | ≤150 | ≤200 | ≤260 | ≤400 |

| Discharging Material Size (mm) | ≤3 (<2mm above 90%) | ≤3 (<2mm above 80%) | ≤3 (<2mm above 80%) | ≤ 3 (<2mm above 80%) | ≤3 (<2mm above 80%) |

| Capacity ( t/h ) | 15-25 | 15-30 | 50-70 | 50-90 | 60-120 |

| Motor Power ( kw ) | 18.5 22 | 22 22 | 37 45 | 55 75 | 75 55 |

| Dimensions (L×W×H )( mm ) | 2560×1020×1650 | 2760×1280×1750 | 3760×1314×2140 | 3870×1700×3150 | 4500×1700×3150 |

Note: Please check the hammerand lubrication system of the double stage crusher periodically, so as toensure crushing efficiency. When the hammer is seriously damaged, please changeit timely.

Links:https://www.globefindpro.com/products/56593.html

-

81H-18A High Speed Dome Camera

81H-18A High Speed Dome Camera

-

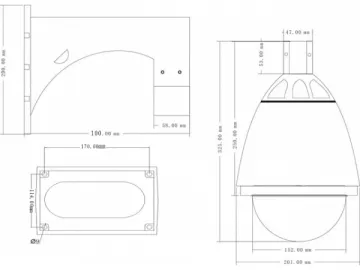

85H High Speed Dome Camera

85H High Speed Dome Camera

-

Spiral Sand Washing Machine

Spiral Sand Washing Machine

-

80H-18A High Speed Dome Camera

80H-18A High Speed Dome Camera

-

Auto Centering Vibration Screen

Auto Centering Vibration Screen

-

Stone Washing Machine

Stone Washing Machine

-

Spiral Chute

Spiral Chute

-

86H-22 High Speed Dome Camera

86H-22 High Speed Dome Camera

-

82H-18A High Speed Dome Camera

82H-18A High Speed Dome Camera

-

83H-18A High Speed Dome Camera

83H-18A High Speed Dome Camera

-

Hammer Crusher

Hammer Crusher

-

Wheel Sand Washing Machine

Wheel Sand Washing Machine