Spiral Classifier

Spiral Classifier

The spiral classifier is commonly used incombination with grinding equipment to form a closed cycle system for mineralprocessing. It is ideal for material pre-classification, and is also applicablefor desliming, dewatering, washing, and classification of mineralmaterials. Spiral classifiers can effectively control the final particle sizeof ground materials, improve the grinding efficiency of grinding mills, andreduce over-pulverizing phenomenon.

Usage and Maintenance

Before starting the spiral classifier, please make sure all bolts arefastened tightly and the gear box is filled with lubrication oil, andmeanwhile, be sure that the impurities and other sundries in the water tankshould be cleared up. In addition, before normal operation, the spiral shaft ofthe classifier should be lifted up and allow the classification equipment to operatewithout load for a while. After that, lower down the spiral shaft slowly, andallow the particles in the water tank to move along the spiral bladesgradually. This can effectively extend the service life of the spiralclassifier.

Technical Parameters of the SpiralClassifier

| Model | Spiral Dia. ( mm ) | Spiral rotating speed ( r/min ) | Water Tank | Classification Capacity ( t/24h ) | Power ( kw ) | Weight ( t ) |

| |||

| Length (mm) | Width (mm) | Slope ( ° ) | Overflow Volume | Sand Return Capacity |

| |||||

| FG-5 | Φ500 | 8.5 | 5000 | 555 | 10-14 | 32 | 143-261 | 1.1 | 1.6 | |

| FG-7.5 | Φ750 | 15.5 | 6000 | 830 | 10-14 | 65 | 256-564 | 3 | 2.83 | |

| FG-10 | Φ1000 | 4.5/9.9 | 7000 | 1112 | 10-14 | 85 | 473-1026 | 5.5 | 4 | |

| FG-12 | Φ1200 | 5/6/7 | 8000 | 1372 | 14-18 | 155 | 1170-1600 | 7.5 | 8.54 | |

| FG-15 | Φ1500 | 2.5/4/6 | 8500 | 1664 | 14-18 | 235 | 1140-2740 | 7.5 | 11.68 | |

| FG-20 | Φ2000 | 3.6/5.5 | 9000 | 2200 | 14-18 | 400 | 3890-5940 | 11 | 20.45 | |

| FG-24 | Φ2400 | 3.6/4 | 10000 | 2600 | 14-18 | 580 | 6800 | 15 | 25.65 | |

| 2FG-12 | Φ1200 | 5/6/7 | 8000 | 2600 | 14-18 | 310 | 2340-3200 | 7.5x2 | 15.84 | |

| 2FG-15 | Φ1500 | 2.5/4/6 | 8500 | 3200 | 14-18 | 470 | 2280-5480 | 7.5 x2 | 21.11 | |

| 2FG-20 | Φ2000 | 3.6/5.5 | 9000 | 4280 | 14-18 | 800 | 7780-11880 | 11 x2 | 36.34 | |

| 2FG-24 | Φ2400 | 3.6/7 | 10000 | 5100 | 14-18 | 1160 | 13600 | 15 x2 | 45.87 | |

Working Principle of the Spiral Classifier

Based on theprinciple that solid particles with different size and specific gravity willsink at different speeds in liquids, the spiral classifier is able to classifylarge sized and small sized granules. Fine particles will be filtered anddischarged from the overflow pipe, while large size particles will be fed intogrinding equipment again via the rotating spiral blades of the classificationequipment.

Links:https://www.globefindpro.com/products/56603.html

-

Rotary Dryer

Rotary Dryer

-

Ore Concentrator

Ore Concentrator

-

Jig Machine

Jig Machine

-

Mesh Belt Dryer

Mesh Belt Dryer

-

AT-6200P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

AT-6200P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

-

Vertical Drying Machine

Vertical Drying Machine

-

High Frequency Screen

High Frequency Screen

-

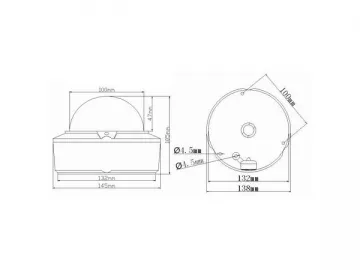

S100 3D Keyboard Dome Camera

S100 3D Keyboard Dome Camera

-

5839DM High Resolution CCTV Camera

5839DM High Resolution CCTV Camera

-

Stone Washing Machine

Stone Washing Machine

-

Auto Centering Vibration Screen

Auto Centering Vibration Screen

-

80H-18A High Speed Dome Camera

80H-18A High Speed Dome Camera