Jig Machine

Jig Machine

Jig machine uses water as the medium to separatemineral ores, by taking advantage of the specific gravity difference betweenthe desired mineral ore and the gangue. It is a kind of gravity separationequipment applicable for separation of tungsten ore, tin ore, alluvial gold,hematite, limonite, manganese ore, titanium ore, antimony ore, lead ore,tantalum ore, niobium ore, etc.We can offer jig machines applicable for materials with different particlesize, so customers can choose a proper type of machine according to the feedingsize.

Our jig machine mainly consists ofmachine frame, separation box, screen and transmissionsystem. Due to the up and down movement of water flow, the mineral ores on thescreen surface will do parabolic motion along with the water flow movement. Dueto specific gravity variation, the mineral ores fall in different speeds. Thus,mineral ores are classified into different layers according to their specificgravity. Ores with smaller specific gravity are finally discharged from adischarging hole and collected as ore concentrate. This is how the jig machineseparates mineral ores.

Technical Parameters of the Jig Machine

| Model | Jig Room | Stroke Coefficient | Diaphragm | Water Consumption (t/h) | Power (kw) | Weight (kg) | |||||||

| Size (mm) | Area (m2) | Row | Rooms | Total Area (m2) | Stroke (mm) | Stroke times | |||||||

| LTP-34/2 | 450 ×300 | 0.135 | 1 | 2 | 0.27 | 0.58 | 0-25 | 320- 420 | 12 | 2-6 | 4-10 | 1.1 | 800 |

| LTA-1010/2 | 1000 ×1000 | 1.0 | 1 | 2 | 2.0 | 0.5 | 0-25 | 250- 350 | 5 | 5-15 | 10-20 | 2.2 | 2890 |

| LTC-69/2 | 600 ×900 | 0.54 | 1 | 2 | 1.08 | 0.55 | 0-50 | 220- 350 | 8 | 6-9 | 40-60 | 1.5 | 1420 |

| 2LTC-366/8T | 600 ×(300-600) | 0.2- 0.34 | 2 | 8 | 2.16 | 0.68- 0.41 | 0-50 | 120- 300 | 5 | 3-6 | 20-40 | 1.1x 2 | 3570 |

| 2LTC-6109/8T | (600-1000) ×900 | 0.58- 0.86 | 2 | 8 | 5.76 | 0.52- 0.35 | 0-50 | 120- 300 | 5 | 10-20 | 80-120 | 2.2x 2 | 4650 |

| AM-30 | 2647 ×2380 | 0.644 | 2 | 2 | 2.574 | 0.47 | 0-50 | 130 | 30 | 10-15 | 100-150 | 3 | 2400 |

Links:https://www.globefindpro.com/products/56607.html

-

Mesh Belt Dryer

Mesh Belt Dryer

-

AT-6200P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

AT-6200P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

-

Vertical Drying Machine

Vertical Drying Machine

-

Ball Mill

Ball Mill

-

AT-4000P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

AT-4000P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

-

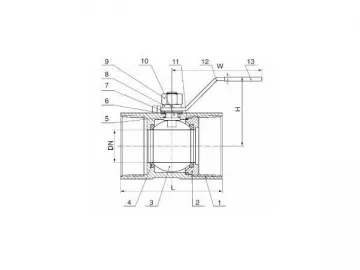

1PC Screwed Ball Valve

1PC Screwed Ball Valve

-

Ore Concentrator

Ore Concentrator

-

Rotary Dryer

Rotary Dryer

-

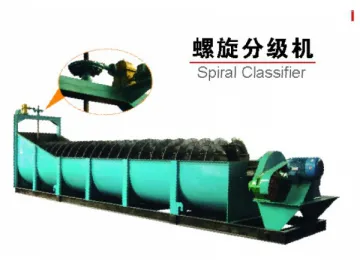

Spiral Classifier

Spiral Classifier

-

High Frequency Screen

High Frequency Screen

-

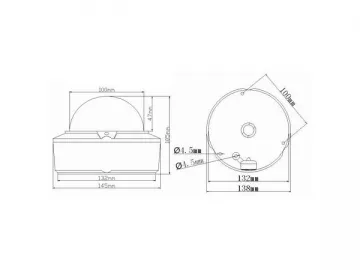

S100 3D Keyboard Dome Camera

S100 3D Keyboard Dome Camera

-

5839DM High Resolution CCTV Camera

5839DM High Resolution CCTV Camera