Vertical Drying Machine

Vertical Drying Machine

The vertical drying machine can be usedin combination with briquette pressing machines to reduce the water content ofbriquettes. It is easy for operation and requires no daily maintenance becauseit has no mechanical moving parts. Being able to work continuously, thevertical dryer offers high drying efficiency and capacity and greatly reduceslabor intensity. Due to its vertical structure, the drying equipment is spacesaving as well.

Our vertical drying machine is achieved through multiple steps, fromdevelopment and design, through industrial testing, product upgrading, to finalmass production and worldwide marketing. Due to the multiple steps, we can makesure our drying equipment has improved energy efficiency, reduced investmentand operation cost, and reliable performance. It is environmental friendly andsafe to use as well.

Working Processes

The briquettes are delivered to the top surface of the vertical drying machineby belt conveyors, and are spread uniformly there with the help of a materialspreading device. When the briquettes move downward slowly on the track, theyundergo heat exchange with the strong inlet air. Meanwhile, the moistureevaporated from the briquettes is dispersed by the strong air. After approximatelytwo hours’ drying, the drying machine can offer dried materials with moisturecontent between 3% and 5%.

Technical Parameters of the VerticalDrying Machine

| Model | Water Content before Drying (%) | Water Content after Drying (%) | Coal Consumption (kg/h) | Drying Time (h) | Inlet Air Temperature (℃) | Drying Capacity (t/h) | Power (kw) |

| LH-1800 | 8-12 | 3-5 | ≤40 | 2-2.5 | 200-260 | 2-3 | 11 |

| LH-2800 | 8-12 | 3-5 | ≤100 | 2-2.5 | 200-260 | 6-8 | 22 |

| LH-3200 | 8-12 | 3-5 | ≤150 | 2-2.5 | 200-260 | 13-15 | 37 |

Links:https://www.globefindpro.com/products/56610.html

-

Ball Mill

Ball Mill

-

AT-4000P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

AT-4000P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

-

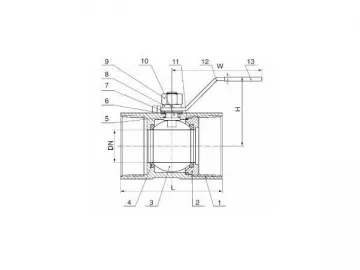

1PC Screwed Ball Valve

1PC Screwed Ball Valve

-

Dry Magnetic Separator

Dry Magnetic Separator

-

Sand Casting

Sand Casting

-

AT-6000PS Selective Band Mobile Phone Repeater / Signal Booster

AT-6000PS Selective Band Mobile Phone Repeater / Signal Booster

-

AT-6200P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

AT-6200P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

-

Mesh Belt Dryer

Mesh Belt Dryer

-

Jig Machine

Jig Machine

-

Ore Concentrator

Ore Concentrator

-

Rotary Dryer

Rotary Dryer

-

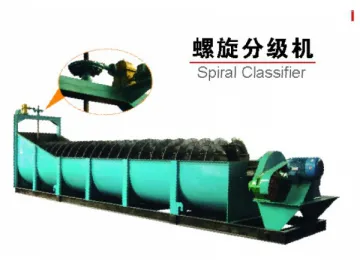

Spiral Classifier

Spiral Classifier