Ball Mill

Ball Mill

The high efficiency ballmill is equipped with a self aligning double row radial spherical rollerbearing, which results in small running resistance and low energy consumption.An additional section of conical material hopper was added to the dischargingend of the original hopper, which increases the effective volume of thegrinding mill and also ensures the uniform distribution of the materials.Our ball mill is widely used for grinding materials in ferrous metal,non-ferrous metal, nonmetallic mineral processing, chemical, and buildingmaterial industries. It is usually used in combination with magnetic separatorand floatation machine for use in mineral processing. Wet grinding and drygrinding are both possible.

Technical Specifications of the BallMill

| Model | Drum Rotate Speed (r/min) | Max. ball loading ( t) | Feeding size (mm) | Discharging size (mm) | Production capacity (t/h) | Power (kw) | Weight (t) |

| YMQ750×1800 | 39 | 1.0 | 0-15 | 0.075-0.3 | 0.3-0.8 | 11 | 3.5 |

| YMQ900×2100 | 37.8 | 1.5 | 0-15 | 0.075-0.3 | 0.8-2.1 | 15 | 5.2 |

| YMQ1200×2800 | 37 | 5.2 | 0-20 | 0.075-0.3 | 1.2-6.2 | 30 | 10 |

| YMQ1500×3500 | 29.7 | 8.0 | 0-25 | 0.075-0.3 | 2.8-9 | 75 | 17 |

| YMQ1500×4500 | 29.7 | 9.5 | 0-25 | 0.075-0.3 | 2.8-10 | 90 | 20 |

| YMQ1830×3600 | 25 | 11.5 | 0-25 | 0.075-0.3 | 5.2-25 | 130 | 28 |

| YMQ1830×4500 | 25 | 16.5 | 0-25 | 0.075-0.3 | 5.2-30 | 155 | 32 |

| YMQ2100×3600 | 24.6 | 17.4 | 0-25 | 0.075-0.3 | 6.5-40 | 180 | 41 |

| YMQ2100×4500 | 24.6 | 22.5 | 0-25 | 0.075-0.3 | 6.5-42 | 210 | 46 |

| YMQ2400×3600 | 22.4 | 23 | 0-25 | 0.075-0.3 | 7.2-92 | 210 | 65 |

| YMQ2400×4500 | 22.4 | 28.5 | 0-25 | 0.075-0.3 | 7.2-95 | 245 | 72 |

| YMQ2700×3600 | 20.7 | 40 | 0-25 | 0.075-0.3 | 12-145 | 320 | 80 |

| YMQ2700×4500 | 20.7 | 50 | 0-25 | 0.075-0.3 | 12-155 | 380 | 90 |

Construction Characteristics and WorkingPrinciple of the Ball Mill

The ball millis a horizontal grinding machine with a turning gear and two sections ofmaterial hopper. It is mainly composed of feeding system, material dischargingsystem, turning gear system, and transmission system. The transmission part ismade up of a reducer, large and small transmission gears, electric motor, andcontrol system.

As you can see from the image, the grinding mill is designed with a largeexternal transmission gear to allow the cylindrical shaped material hopper torotate continuously. Through screw feeding via the quill shaft made of caststeel, the raw materials are uniformly fed into the first section of materialhopper, in which there are stepped lining or corrugated lining and grindingballs in different specifications. The lining is replaceable and offers goodwearing resistance, which helps extend the service life of the ball mill. (:/。- )

When the cylindrical hopper is rotating, the centrifugal force generated duringthe process will bring the balls to a certain height. When the balls arefalling down, they will impact on the materials heavily and thus achieving thegoal of material breaking and pulverizing. This is how the ball mill works.

Test Run

After the ball mill is installed properly,test run of it can be conducted, and should be carried out by a skilled ballmill operator in strict conformation with related safety operation rules.

1. The continuous test running time should be no less than 12-24 hours, and anyproblem occurred during test running should be solved promptly.

2. If idling test is verified to be qualified, loaded test can be started. However, loaded test for the ball mill shouldbe divided into different steps.

(1) Test the ball mill for 12-24 hours, with proper amount of raw material and1/3 grinding balls.

(2) Test the grinding mill for 24-48 hours, with 2/3 balls. After this,operators should check the grinding equipment once more and fasten all boltstightly again.

3. The actual testing time and load conditions should be determined accordingto the gear mechanism operation conditions, like temperature rising, runningnoise, and gear tooth contact, etc. Before the gear tooth contact condition reachesthe designed requirements, the ball mill is not allowed to run with full load.

4. During test running process, the cooling system and lubrication system ofthe ball mill should work normally. The main bearing, transmission bearing andreducer temperature should be in normal conditions.

5. Records should be carefully made during test running.

The lining inside the ball mill’s cylindrical material hopper

Links:https://www.globefindpro.com/products/56611.html

-

AT-4000P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

AT-4000P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

-

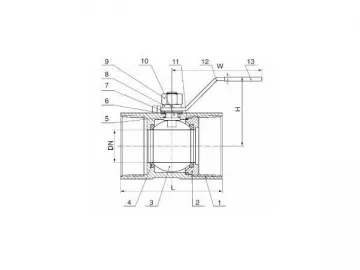

1PC Screwed Ball Valve

1PC Screwed Ball Valve

-

Dry Magnetic Separator

Dry Magnetic Separator

-

Sand Casting

Sand Casting

-

AT-6000PS Selective Band Mobile Phone Repeater / Signal Booster

AT-6000PS Selective Band Mobile Phone Repeater / Signal Booster

-

2PC Flanged Ball Valve

2PC Flanged Ball Valve

-

Vertical Drying Machine

Vertical Drying Machine

-

AT-6200P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

AT-6200P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

-

Mesh Belt Dryer

Mesh Belt Dryer

-

Jig Machine

Jig Machine

-

Ore Concentrator

Ore Concentrator

-

Rotary Dryer

Rotary Dryer