Dry Magnetic Separator

Dry Magnetic Separator

The dry magnetic separator offers high iron ore recovery rate, due toits high magnetic field intensity and uniform magnetic field distribution aswell as high magnetic permeability. It is especially designed for use in lowgrade iron ore separation and applicable for materials with maximum particlesize of 12mm. The dry magnetic separationequipment can also be utilized for iron removal in coal, nonmetallic ore, andbuilding material industries.

Compared with wet type separation equipment which requires liquid as diluents,dry type ones have higher separation efficiency. Our dry magnetic separator requires that thefeeding materials should be dry, and the solid particles should be able to movefreely. Or else, the separation efficiency may be reduced.

Technical Parameters of the Dry MagneticSeparator

| Model | Drum Size (mm) | Magnetic Field Strength (Gs) | Drum Speed (m/s) | Power (kw) | Separation Capacity | Weight (kg) | Note | |

| t/d | m3/d | |||||||

| CTG-7522 | Φ 750 × 2200 | 2000-3500 | 40 | 3 | 2500 | 1800 | 1300 | Permanent magnetic separation |

| CTG-7526 | Φ 750 × 2600 | 2000-3500 | 35 | 4 | 3000 | 2200 | 1500 | |

| CTG-9022 | Φ 900 × 2200 | 2000-3500 | 38 | 5.5 | 3000 | 2200 | 1600 | |

| CTG-9026 | Φ 900 × 2600 | 2000-3500 | 28 | 5.5 | 3500 | 2500 | 1900 | |

| CTG-1024 | Φ 1050 × 2400 | 2000-3500 | 28 | 7.5 | 3500 | 2500 | 2200 | |

| CTG-1030 | Φ 1050 × 3000 | 2000-3500 | 22 | 11 | 4000 | 2800 | 2600 | |

| CTG-1230 | Φ 1200 × 3000 | 2000-3500 | 22 | 11 | 4200 | 3000 | 3000 | |

| CTG-1240 | Φ 1200 × 4000 | 2000-3500 | 22 | 15 | 5000 | 3500 | 3800 | |

Links:https://www.globefindpro.com/products/56614.html

-

Sand Casting

Sand Casting

-

AT-6000PS Selective Band Mobile Phone Repeater / Signal Booster

AT-6000PS Selective Band Mobile Phone Repeater / Signal Booster

-

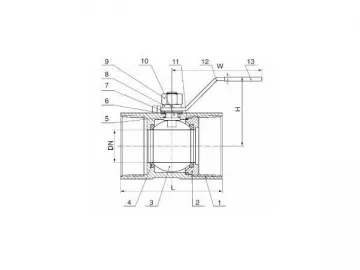

2PC Flanged Ball Valve

2PC Flanged Ball Valve

-

AT-6000GS Selective Band Mobile Phone Repeater / Signal Booster

AT-6000GS Selective Band Mobile Phone Repeater / Signal Booster

-

AT-6100CP Dual Band Mobile Repeater / Signal Booster

AT-6100CP Dual Band Mobile Repeater / Signal Booster

-

AT-6000WS Selective Band Mobile Phone Repeater / Signal Booster

AT-6000WS Selective Band Mobile Phone Repeater / Signal Booster

-

1PC Screwed Ball Valve

1PC Screwed Ball Valve

-

AT-4000P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

AT-4000P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

-

Ball Mill

Ball Mill

-

Vertical Drying Machine

Vertical Drying Machine

-

AT-6200P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

AT-6200P GSM/CDMA/DCS/PCS/WCDMA Cell Phone Repeater

-

Mesh Belt Dryer

Mesh Belt Dryer