CG510S AMPS Terpolymer Cement Fluid Loss Additive

CG510SAMPS Terpolymer CementFluid Loss Additive

Our AMPS terpolymer cement fluid lossadditive can be further classified into two categories, CG510S-D type andCG510S-T type. Both of them share some similarities and differences. Forexample, these two fluid loss additives both present in the form of powder andcome with less than 15% residues on a 0.315mm sieve. They are both made of 50%AMPS copolymer with the CAS number of 40623-75-4 and have a little bit pungentodor. For the CG510S-D AMPS terpolymercement fluid loss additive, the left 50% ingredient is slag or silica flour.For the CG510S-T type, the remaining 50% component is sodium chloride, with theCAS registry number of 7647-14-5.

Our white CG510S-D AMPS terpolymercement fluid loss additive has a bulk density of 0.90±0.10 g/cm3 andfeatures1.70±0.05 relative density to water. It is partially dissolved in waterand is not easy to become damp and agglomerated. It can be stored for a longtime under appropriate conditions. Therefore, this fluid loss additive is ourrecommended product for dry mixing purpose. While our white CG510S-T AMPS terpolymer cement fluid lossadditive is completely soluble in water and features a pH VALUE of 5.0±1.0.With a relative density of 1.70±0.05 and a bulk density 0.80±0.10g/cm3, thisfluid loss additive is applicable to dry mixed and water mixed cement. Storedfor a long time, this cement additive is apt to caking, which will also depressthe mobility and increase the difficulty in water mixing without influencing theproduct performance.

The CG510S AMPS terpolymer cement fluid lossadditive is applicable to cement slurry coming in different compositions. Thecement slurry in fresh water system is mainly composed of 700g API class Gcement, 308g fresh water, 12.6g (1.8%) CG510S AMPS terpolymer cement fluid loss additive or 6.3g (0.9%)CG510S-P pure type. Inaddition, the cement slurry in brine system consists of 600g cement, 438g18%brine, 210g silica flour, and 27g (4.5%) CG510S standard fluid loss additive. Within a certaintemperature range, our recommended dosage of the AMPS terpolymer cement fluid loss additive is 1.8% by weigh of cement (BWOC),and the generally adopted dosage is 1.6-4.0% by weigh of cement (BWOC). The followingtable below shows the performance of cement slurry, using our AMPS terpolymer cement fluid lossadditive as one important ingredient.

| Item | Technical Indicators | |

| Initial consistency, Bc | 80℃/45min, 46.5MPa | ≤30 |

| Thickening time, min | 100-200 | |

| Fluid loss, ml | 90℃, 6.9MPa | ≤50 |

| 18%Brine fluid loss, ml | ≤120 | |

| Free fluid, ml | 90℃, atmospheric pressure | ≤3.5 |

| 24h Compressive strength, MPa | ≥14 | |

Kelioil is a professionalAMPS terpolymer cementfluid loss additive manufacturer in China. Our company offers a varietyof cementing additives, including fluid loss additive, cement dispersant, retarder, cement defoamer, and much more.

Links:https://www.globefindpro.com/products/56861.html

-

Carpet Protection Film

Carpet Protection Film

-

Floor Protection Film

Floor Protection Film

-

Tile Protection Film

Tile Protection Film

-

Oval Whirlpool Bathtub

Oval Whirlpool Bathtub

-

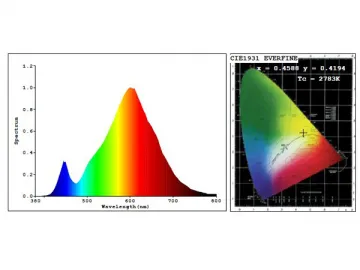

5W C2 Dimmable Chandelier LED Bulb

5W C2 Dimmable Chandelier LED Bulb

-

AR111 10W LED Spot Light

AR111 10W LED Spot Light

-

Plastic Board Protection Film

Plastic Board Protection Film

-

Sports LED Display Screen

Sports LED Display Screen

-

Stainless Steel Sheet Protection Film

Stainless Steel Sheet Protection Film

-

Asphalt Batching Plant

Asphalt Batching Plant

-

CF210 Naphthalene Moderate Temperature Cement Dispersant

CF210 Naphthalene Moderate Temperature Cement Dispersant

-

Road Maintenance Truck

Road Maintenance Truck