Liquid Spacer Agent Additives

LiquidSpacer Agent Additives

The CS210S liquid spaceragent additive can be mixed with fresh water to produce the well cement spacerwith proper viscosity. It caneffectively replace the drilling mud, and prevent blending between cementslurry and drilling mud. Our liquid spacer agent additive has good thickeningeffect, and its aqueous solution with low concentration can achieve highviscosity. Theaqueous solution of this spacer agent additive has good suspension ability, so weighting agent,insoluble solids and droplets can be suspended in the CS210S aqueous solution.In addition, our spacer agent additive also has good salt tolerance, acid tolerance and alkalitolerance, so it can be well compatible with acid, alkali, salt in the samesolution. Besides, this spacer additive can be used in conjunction with other thickening agent. It is easy to dissolve, easy to use and features stableperformance.

Our liquid spacer agent additive should go through compatibility tests prior to use. It has thickening effecton cement slurry under certain conditions, so the slurry should be separated byappropriate amount of inert spacer liquid, like fresh water or low salinitywater. The spacer agent additive is efficient when the bottom holecirculating temperature is lowerthan 248℉or120℃, and comes with the general dosage of 0.5-4.0% by weight ofcement (BWOC) and the recommended amount of 2.0% BWOC. The spacer fluid is composed of 1600g water and 32g(2%) liquid spacer agent additive. This spacer fluid achieves a marsh funnel viscosity ofno less than 200s, which is measured by a marsh funnel. It also has a highviscosity of more than 5000mPa·s, which is measured by a viscometer.

Properties and Composition of Liquid Spacer Agent Additives

Our liquid spacer agent additive is a faint yellow powder. It is nonflammable and inexplosive and has slightly pungent odor. Itis completely soluble inwater under normal temperature, and achieves a high fineness of no morethan 15% residues on a 0.315mm sieve. The liquid spacer agent additive has abulk density of 1.10±0.10g/cm3and a pH value of7.0±1.0 when coming in 5% aqueous solution. It is madeup of 10% polyethyleneglycol with the CAS number of 25322-68-3. The oral LD50 value of this componentis 348000 mg/kg. This spacer agent additive also comprises 70% starch graft polymers with theCAS number of 9005-25-8, and also 20% potassium formate with the CAS number of 590-29-4.

Hazards Identification of Liquid Spacer Agent Additives

This liquid spacer agent additive has no carcinogenicity, but will become apotential hazard to both human body and ecological environment. It is slightlytoxic to fish and animal. Generally speaking, the spacer agent additiveirritates eye and skin slightly through skin or eye contact, and has astimulating effect on the oral cavity and stomach by accidental ingestion, aswell as irritates the mucosal and respiratory tract of the person who inhalesthe additive accidentally. This liquid spacer agent additive will also induceskin redness, eye irritant and lead to nausea, vomiting, cough and prickle andother symptoms.

Emergency Treatment of Liquid Spacer Agent Additives

When in skin contact with the liquid spacer agent additive, the person shouldput off the contaminated clothing and rinse it with soapy and clean flowingwater. When the cement additive gets into eyes, the person should raise theeyelid, and rinse it with plenty of clean flowing water and physiologicalsaline. If careless inhalation happens, the person should escape to fresh air.The person who ingests the liquid spacer agent additive accidentally shoulddrink plenty of water to induce vomiting. If the above first aid measuresdidn’t work, the person should ask for a doctor. Once the liquid spacer agentadditive is released accidentally, the user should immediately wear thepersonal protective equipment, collect the available leakage, and clean thespill site. When the spacer agent additive burns, the common fire fightingmedium like foam, dry powder, carbon dioxide, water can all be used to put out thefire, with no need for any special fire-fighting equipment.

Handling and Storage of Liquid Spacer AgentAdditives

The liquid spacer agent additive should be kept in aclosed container when not in use. It should be stored in a dry and cool place,prevented from the sun and rain, and kept away from the heat and fire andincompatible materials like strong oxidizers. In most cases, places providingexhaust ventilation can well protect and keep the spacer agent additive in goodcondition. In addition, necessary personal protective equipments are alsorequired. For example, a dusk mask forrespiratory protection, standard protective clothing and gloves for skinprotection, and chemical splash goggles for the protection of eye. By the way,smoking, dining and water drinking are all forbidden on the working site. The waste liquid spacer agent additive shouldbe properly buried or handled according to local environment requirement, andthe packaging of the liquid spacer agent additive should be transferred to thedumping site for proper disposal.

Transport and Regulatory Information

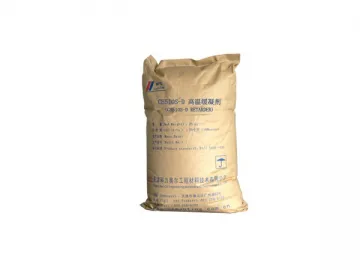

The liquid spacer agentadditive is applied to industry only. It is not included in the dangerous goodstransport international regulations of IMDG, IATA, and ADR/RID. It is packed inthe 25kg composite bag. In addition, the liquid spacer agent additive can alsobe packed according to user requirements. Our liquid spacer agent additive iscompliant with a series of regulations, including the Management Regulations ofDangerous Chemicals Management, the Practical Detailed Rules and Regulation forDangerous Chemicals Management, the Classification and mark of Common ChemicalProducts (GB 13690-2009), the General Rule of Common Chemical Products(GB15603-1995), and the Technology Conditions for the Packing Marks forHazardous Cargo (GB 12463 -1990).

As a professional liquid spacer agent additive manufacturer and supplier in China, Kelioil also providesnon-phosphorus concrete washing liquid, cement dispersant, retarder, fluid loss additive, and much more.

Links:https://www.globefindpro.com/products/56900.html

-

CH510S-D High Temperature Cement Retarder

CH510S-D High Temperature Cement Retarder

-

CF310L Polycarboxylates Moderate Temperature Cement Dispersant

CF310L Polycarboxylates Moderate Temperature Cement Dispersant

-

CG610S-P AMPS Quadripolymer Cement Fluid-Loss Additive (High Purity Powder)

CG610S-P AMPS Quadripolymer Cement Fluid-Loss Additive (High Purity Powder)

-

Advertising CNC Router

Advertising CNC Router

-

Anti Fluid Channeling Latex Cement Additive

Anti Fluid Channeling Latex Cement Additive

-

Cling Film Rewinding Machine

Cling Film Rewinding Machine

-

YAG Laser Cutting Machine

YAG Laser Cutting Machine

-

CG610S AMPS Quadripolymer Cement Fluid Loss Additive

CG610S AMPS Quadripolymer Cement Fluid Loss Additive

-

Large Scale Laser Engraving Machine

Large Scale Laser Engraving Machine

-

Curved Shower Enclosure

Curved Shower Enclosure

-

7W GLS LED Bulb Light A60

7W GLS LED Bulb Light A60

-

Acrylic Shower Tray

Acrylic Shower Tray