Three Layer Stretch Film Making Machine

ThreeLayer Stretch Film Making Machine

Our three layer stretchfilm making machine is a result we combine our endeavor and advanced techniqueabsorbed from abroad. It focus on the manufacture of new type stretch film,tensile membrane, cast film, and etc.This machine unit is fed with LLDRE and different model resin to produce thefilm which has double or triple layers and single-face or double-faceviscosity. Thefinished film from this machine can be high impact and prick resistant and usedwidely in packing and shipping bulk goods.

This machine uses PLC and quality transmission system to ensure the stableprocess of material feeding in and film coming out. Its coiling system isequipped with high precision servo driver and mechanical reloading arm. Togetherwith cutter and filter changer, this coiling system gives the whole film makingmachine possibility to work continuously and efficiently. In addition themachine features side waste recycling system and swing device to make sure thelower cost and more pretty and competitive output.

1.The composite film from our stretch film makingmachine has better performance in preservation and stickiness.

2.We give the film makingmachine possibility to save cost. This machine can be fed with ordinary PErather than expensive imported material. By now we enhance its configurationwith world famous ABAdistribution technique which allows it to produce triple-layer film only by twoextruders. As long as the replacement match, and production AB or BA typedouble-layer co-extrusion film.

3 It is easy to operate the machine. User can depend on the PLC,HMI, integration of machineelectronics and pneumatic tocontrol each part of machine.

Main Technical Parameter

| Model | SLW-1000 ( 3 layers) |

| Screw Diameter | 45mm/44mm/65mm |

| L/D ratio | 28:1 |

| Screw Barrel Material | 38CRMOLA |

| Mould width | 1250mm |

| Film Width | 1000mm |

| Thickness | 0.013-0.05mm |

| Structure of film layers | A/B/C |

| Winding Diameter | 300mm |

| Output | 125kg/h |

| Liner speed of machine | 120m/min |

| Total power | 120kw |

| Overall dimension: | 6500×4000 ×3600mm |

| Total Weight | 10T |

| Standard Configuration | ||

| Item | Description | Quantity |

| 1 | Automatic Winding changer | 1pcs |

| 2 | Automatic Air shaft | 2pcs |

| 3 | Automatic Trimming device | 1pcs |

| 4 | Temperature Control | 12unit |

| 5 | Step less Inverter | 1set |

| 6 | Step Motor | 1set |

| 7 | AC Motor | 1set |

| 8 | PLC touch screen | 1set |

| 9 | Gear box | 1set |

| 10 | Panel box | 1set |

| 11 | Switch (ZHENGTAI) | Several pcs |

| 12 | Electrical component (ZHENGTAI) | Several pcs |

| 13 | Ceramic Heater | 1pcs |

| 14 | Cooling roll (diameter: 270mm) | 1pcs |

| 15 | Air compressor | 1pcs |

| Spare Parts and Accessories | ||

| Item | Description | Quantity |

| 1 | Tools | 1pcs |

| 2 | Instructions | 1pcs |

| 3 | Schematic | 1pcs |

| 4 | Current meter | 1pcs |

| 5 | Voltage meter | 1pcs |

| 6 | Thermocouple | 1pcs |

| 7 | Relay | 1pcs |

SLW-1000,SJ-70*28SJ-55*28,70mm55mm

Send Message

Links:https://www.globefindpro.com/products/56957.html

-

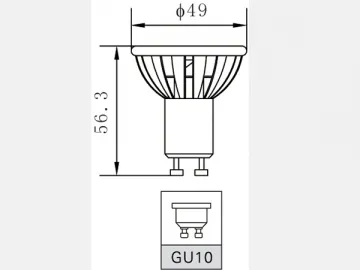

Ceramic 4W LED Spotlight

Ceramic 4W LED Spotlight

-

600 Single Layer Stretch Film Making Machine

600 Single Layer Stretch Film Making Machine

-

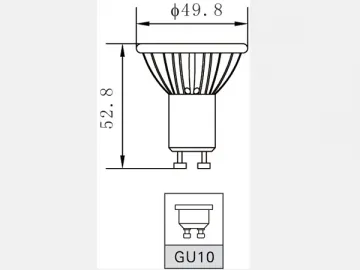

Aluminum 3.5W LED Spotlight

Aluminum 3.5W LED Spotlight

-

US908 RF CO2 Fractional Laser Machine

US908 RF CO2 Fractional Laser Machine

-

US418 Laser Hair Removal Machine

US418 Laser Hair Removal Machine

-

IPL Skin Rejuvenation Machine

IPL Skin Rejuvenation Machine

-

Gocare Hair Molding Clay

Gocare Hair Molding Clay

-

Posa Argan Oil

Posa Argan Oil

-

Aluminum 6W LED Spotlight

Aluminum 6W LED Spotlight

-

Ceramic 3W LED Spotlight

Ceramic 3W LED Spotlight

-

50W LED Flood Light

50W LED Flood Light

-

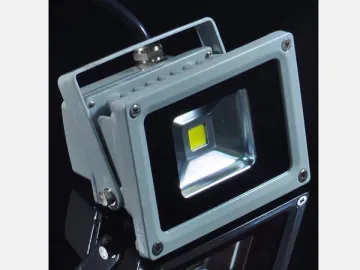

10W LED Flood Light

10W LED Flood Light