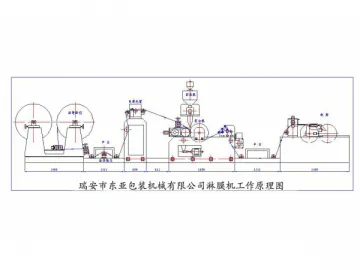

Film Lamination Machine

Film LaminationMachine

Main Technical Parameter

| Model | SJ-85-1350 |

| |

| Width of finished product | 600-1200mm |

| |

| Max compounding speed | 50-110m/min |

| |

| Thickness of lamination | 0.01-0.08mm |

| |

| L/D of screw | 28:1 |

| |

| Laminating layers | 2-3 layers |

| |

| Output | 10-200/20-200kg/h |

| |

| Overall dimension |

|

| 12500x7000x3200mm |

| Power | 70/80kw |

|

|

| Applicable for basic material | PP, PE, PAPER, BOPP BOPET BOPA CPP CPE |

|

|

Details

1. Extruder:

Screw Ф95/80mm,L/D=30:1×2

screwmaterial 38CRMOALalloy steel,treated by nitrification

cylinderpipe heating stainlesssteel,electriccapacity 25KW

temperature controll auto5point temperature controller

drivemotor 22kw(screen changer)

extruder frame

structure stainlesssteel jointed together

horizontal moving speed 5 meter/min

horizontal moving 2HPmotor,2600M/M

vertical moving man power to ajust

vertical moving range ±40MM

3 phase connect

material 45#steel

heating fashion stainlesssteel heating board,electric capacity6kw

temperature control auto 2 point temperaturecontroller

2.T type mould:

width 1250mm

material treated steel

mould material treatedsteel,surface polishing

gap 0.3-1.0MM

electric capacity 17kw/12kw

heating fashion inner stainless steel pipe

temperature control auto 5 points temperature controller

3.Laminating equipment:

type three wheelextruding lamination

structure stainless steeljointed together

cool steel wheel Ф500mm×1200mmwidth

surfacetreated and polishing,double inner shell

singleflow volution cool water,cool water screw connector as attachment

silicon rubber wheel Ф300mm×1200mmwidth

surfacetreated by silicon rubber,

innercool water,screw connector

fashion of pressure wheel air pump

back pressure wheel Ф270mm×1200mmwidth

surfacetreated and polishing,inner cool water,screw connector

spread wheel Ф100mm×1200mmwidth×2pcs

idler pulley steel wheel

drive motor 4kw×2(screen changer)

4.Sidecutting equipment:

type round cutter

round cutter surface treated×2pcs

cutter wheel Ф90mm×1000mm width

cutter wheeltransmission lamination tap motor

side waste out 2HP air fan

5.Rewinderequipment:

type doublerewinding

width 1300mm(max)

diameter Ф800mm(max)

frame structure stainless steel jointedtogether

drive motor YLJ-16-6 three phasemoment motor 2pcs

scroll Ф75mm air scroll

jointed fashion auto rewinding changer

cutting fashion air cutter

6. Electric, air pressurecontrol and equipment operation(operationcontrolling case)

Fission equipment,for convenient operation and good view

extruder auto temperaturecontroller

laminating equipment air pressure control, operation switchetc

tap tensioncontrol switch, air correct system

rewinding equipment drive control and operation switch,rewinding switch

air pressure control equipment,operation switch etc

7. Main spare list

Extruder reducer guomaojiangsu

Cylinder screw zhoushan zhejiang

Main motor zhejiang

T type mould jingcheng zhejiang

Tow-up motor zhejiang

Rewinding motor zhejiang

Screen changer adsen

Heating unit jiangsu

Main electric unit zhengtaichina

air pressureunit shanghai

side cutter shanghai

correct equipment auto correct system taiwan

tension control auto tension control system taiwan

,,、BOPP、BOPET,、。SJ-85-1350600-1200,0.01-0.06mm,,,,。,。、,,。,24,50-110/,。,,。

Links:https://www.globefindpro.com/products/57021.html

-

LED Light Bulb

LED Light Bulb

-

Kupa One Minute Hair Treatment

Kupa One Minute Hair Treatment

-

US800 CO2 Fractional Laser Machine

US800 CO2 Fractional Laser Machine

-

US301 Bipolar RF Equipment

US301 Bipolar RF Equipment

-

US790 PDT LED Light Beauty Machine

US790 PDT LED Light Beauty Machine

-

US408 Laser Hair Removal Equipment

US408 Laser Hair Removal Equipment

-

Featha Hair Color Cream

Featha Hair Color Cream

-

Film Laminating Machine

Film Laminating Machine

-

US306 Ultrasonic Cavitation Slimming Machine

US306 Ultrasonic Cavitation Slimming Machine

-

Digital Display Hydraulic Paper Cutting Machine

Digital Display Hydraulic Paper Cutting Machine

-

US601 E-Light IPL RF Beauty Machine

US601 E-Light IPL RF Beauty Machine

-

US609 E-Light IPL RF Beauty Equipment

US609 E-Light IPL RF Beauty Equipment