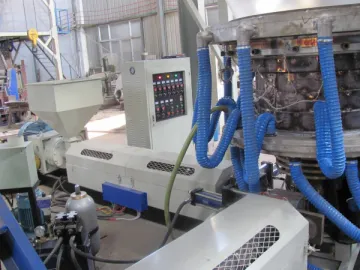

600 Single Layer Air Bubble Film Making Machine

600 Single Layer Air Bubble Film Making Machine

Our 600 single layer air bubble film making machine adopts once throughforming craft and inner water cycle cooling machine. Its design uses domesticand international advanced technologies. Its configuration adopts branded unitsincluding the hard gear reducer made in Jiangsu,the cylinder screw made in Zhoushan,T mould special designed for fast filter changing, double molding roller,manual clutch, HOLIP branded variablefrequency device from Denmark, quality heating tube and bearing made ofstainless steel, etc. This filmingmaking machine has high yield of about 40Kg per hour and the size of finished air bubble filmcan be customized in an available range. It is equipped with double scrollingsystem which can ensure the continuous and reliable running. In addition it has rational design, outstanding outlooking and simple operation.

Main Technical Parameter

| Model | DY-600 |

| Main and auxiliary extruder screw diameter | Φ55mm |

| Screw L/D ratio | 28:1 |

| Main and auxiliary extruder electrical power | 11KW |

| Width of finished product | 600mm |

| Main bubble specification | 10×3.4mm, 6×3.2mm, 25×10mm, 30×10mm |

| Output | 30-40kg/h |

| Total installed capacity | 40kw |

| Overall dimension | 7000mm×2000mm×2500mm |

| Gross weight | 2.8T |

1. Extruder

Structure

Frequencyconversion velocity modulation, special-purpose velocity modulation motor,

Speedreducer for the refined ZLYJ plastic rubber to squeeze out

38CRMOALalloy steel cylinder screw

Fastnet change organization

Stainlesssteel heating coil

Forcesthe air circulation blower

Specification

Drivingmotor: 11KW (frequency conversion velocity modulation)

Retarder: output torque 2500N.M

Cylinderscrew: Ф55mm,L/D=28:1

Cylinderheat: heating capacity 20KW

Fastfilter net change: lead screw nut promotion, lifting capacity 20KN

Temperaturecontrol: four zones auto-temperature control, max 400℃

Pushoutput: 40kg/h

2. T -mold

Structure

T flow channel specially designed

Mold lip gap multi- spots regulation

The mold lip width adjust in permission scope

Stainless steel heating pipe built in

Specification

Mold lip gap: 0.3-1.0mm

Mold lip width: 200-600mm

Electric heating capacity: 20KW

3. Shape Part

Structure

a pair of 6mm and 10mmmain rollers, circulating water internal cooling, bubble specification can bemade by customer

The manual clutch organization

Shape roller tow motor

Shape roller motor operated onset and retreatsystem

Specification

Bubble diameter: Ф6mm, Ф8mm, Ф10mm, Ф25mmФ30mm or customized

Bubble height: 3mm

Bubble effective width: 600mm

Shape roller diameter: 245mm

Shape roller driving motor: 0.55KW

Shape roller max mechanical speed: 35M/Min

Shape roller level traveling speed: 5M/Min

4. Towing Part

Structure

Tow roll of double rollers

Cutter and itemize device

Specification

Roller diameter: Ф 210mm

Roller max mechanical speed: 35M/Min

Roller effective traction width: 600mm

Roller driving motor: 0.75KW

5. Rewinding Part

Structure

Double axle and station rewinders

Double axle manual clutch change

Auto-alarm with fixed length

Specification

Rewinding width: 600mm

Rewinding diameter: 600mm

Rewinding torque motor: 16N.M

6. Electronic Control

The electrical fission control system of ourmachine features the simple and convenient operation, Chinese and Englishlanguage interface, branded parts whichhave good quality and long service life. All these give our single layer airbubble film making machine more humanization andsimplification

7. Spare Parts and Tools

| Standard configuration | ||

| Item | Description | quantity |

| 1 | Forming roller | 1pcs |

| 2 | Automatic Trimming device | 1pcs |

| 3 | Automatic Temperature Control | 12unit |

| 4 | Step less Inverter | 1set |

| 5 | Step Motor | 1set |

| 6 | AC Motor | 1set |

| 7 | Gear box | 1set |

| 8 | Panel box | 1set |

| 9 | Switch (ZHENGTAI) | Several pcs |

| 10 | Electrical component (ZHENGTAI) | Several pcs |

| 11 | Hopper | 1pcs |

| 12 | Cooling roll (diameter: 270mm) | 1pcs |

| 13 | Air compressor | 1pcs |

| var chat_param = new Object(); chat_param.chatid = "593"; chat_param.url = ""; etw_init(chat_param); document.getElementById('ETWyear').innerHTML=new Date().getFullYear(); |

Links:https://www.globefindpro.com/products/57118.html

-

Morocco Argan Oil Keratin Protein Hair Mask

Morocco Argan Oil Keratin Protein Hair Mask

-

Above Counter Ceramic Basin

Above Counter Ceramic Basin

-

Kupa Vitamin Hair Repair Spray

Kupa Vitamin Hair Repair Spray

-

Hairdesign Vitamin Hair Repair Spray

Hairdesign Vitamin Hair Repair Spray

-

Hairdesign Botanical Regrowth Shampoo

Hairdesign Botanical Regrowth Shampoo

-

OSRAM/Cree Adjustable LED Road Light

OSRAM/Cree Adjustable LED Road Light

-

1500 Co-Extrusion Double Layer Film Blowing Machine

1500 Co-Extrusion Double Layer Film Blowing Machine

-

2000 Co-Extrusion Double Layer Film Blowing Machine

2000 Co-Extrusion Double Layer Film Blowing Machine

-

Kupa Anti Drandruff Shampoo for Women

Kupa Anti Drandruff Shampoo for Women

-

Counter Top Ceramic Basin

Counter Top Ceramic Basin

-

Adjustable LED Ceiling Light

Adjustable LED Ceiling Light

-

5050 SMD LED Strip Light

5050 SMD LED Strip Light