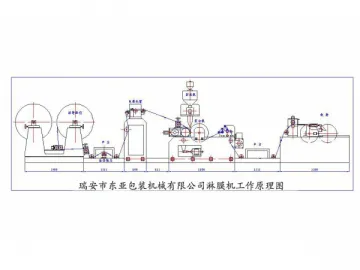

High Speed Film Laminating Machine

High Speed Film Laminating Machine

MainTechnical Parameter

| Model | SJ-85-1350 | SJ-90-1650 |

| Width of finished product | 600-1200mm | 1100-1500mm |

| Max. compounding speed | 50-110m/min | 50-110m/min |

| Thickness of lamination | 0.01-0.06mm | 0.01-0.06mm |

| L/D ratio of screw | 28:1 | 28:1 |

| Max. diameter for unwinding and rewinding | 1200mm | 1200mm |

| Overall dimension | 12500×7000×3200mm | 13000×8000×3200mm |

| Power | 75kw | 95kw |

| Applicable for basic material | BOPP, BOPET, BOPA, CPP, CPE | |

Mainspec.

material PP, PE, PAPER,BOPP BOPET BOPA CPP CPE original material PP, PE or kraft paper(below 200G) or white board paper orspinning or knitting cloth or oiled paper etc

laminating thickness 0.012-0.06MM

originalmaterial spec width 1500MM(max)

speed 110meter/min(max)

productivity 100meter/min(max)

extrusion quantity 120Kg/h

extruder screwФ90MM,L/D=28:1

laminating equipment cool steel pipe

Ф500MM×1500MM width

rewinder double rewinding

Details

1. Extruder:

screw Ф90MM,L/D=28:1

screwmaterial 38CRMOALalloy steel,treated by nitrification

cylinderpipe heating stainlesssteel,electriccapacity 35KW

temperature controll auto5point temperature controller

drivemotor 30KW(screen changer)

extruder frame

structure stainlesssteel jointed together

horizontal moving speed 5meter/min

horizontal moving 2HPmotor,2600M/M

vertical moving man power to ajust

vertical moving range ±40MM

3 phase connect

material 45#steel

heating fashion stainlesssteel heating board,electric capacity6KW

temperature control auto 2 pointtemperature controller

2.T type mould:

width 1650MM

material treated steel

mould material treatedsteel,surface polishing

gap 0.3-1.0MM

electric capacity 25KW

heating fashion inner stainless steel pipe

temperature control auto 5 points temperature controller

3.Laminating equipment:

type three wheelextruding lamination

structure stainless steeljointed together

cool steel wheel Ф500MM×1200MMwidth

surfacetreated and polishing,double inner shell

singleflow volution cool water,cool water screw connector as attachment

silicon rubber wheel Ф300MM×1200MMwidth

surfacetreated by silicon rubber,

innercool water,screw connector

fashion of pressure wheel air pump

back pressure wheel Ф270MM×1500MMwidth

surfacetreated and polishing,inner cool water,screw connector

spread wheel Ф100MM×1500MMwidth×2pcs

idler pulley steel wheel

drive motor 7KW(screen changer)

4.Sidecutting equipment:

type round cutter

round cutter surface treated×2pcs

cutter wheel Ф90MM×1200MM width

cutter wheeltransmission lamination tap motor

side waste out 2HP air fan

5.Rewinderequipment:

type double rewinding

width 1500MM(max)

diameter Ф1000MM(max)

frame structure stainless steel jointedtogether

drive motor YLJ-16-6 three phasemoment motor 2pcs

scroll Ф85MM air scroll

jointed fashion auto rewinding changer

cutting fashion air cutter

6. Electric, air pressurecontrol and equipment operation(operationcontrolling case)

Fission equipment,for convenient operation and good view

extruder auto temperaturecontroller

laminating equipment airpressure control 、operation switch etc

tap tensioncontrol switch、air correct system

rewinding equipment drivecontrol and operation switch、rewinding switch

airpressure control equipment、operation switch etc

7. Main spare list

Extruder reducer guomaojiangsu

Cylinder screw zhoushan zhejiang

Main motor zhejiang

T type mould jingcheng zhejiang

Tow-up motor zhejiang

Rewinding motor zhejiang

Screen changer adsen

Heating unit jiangsu

Main electric unit zhengtaichina

air pressureunit shanghai

side cutter shanghai

var chat_param = new Object();

chat_param.chatid = "593";

chat_param.url = "";

etw_init(chat_param);

document.getElementById('ETWyear').innerHTML=new Date().getFullYear();

Links:https://www.globefindpro.com/products/57161.html

-

70W LED Tunnel Light

70W LED Tunnel Light

-

Posa Anti Dandruff Shampoo

Posa Anti Dandruff Shampoo

-

1500 LLDPE Mulch Film Blowing Machine

1500 LLDPE Mulch Film Blowing Machine

-

2000 LLDPE Mulch Film Blowing Machine

2000 LLDPE Mulch Film Blowing Machine

-

7W LED Ceiling Light

7W LED Ceiling Light

-

1200 PE Film Blowing Machine

1200 PE Film Blowing Machine

-

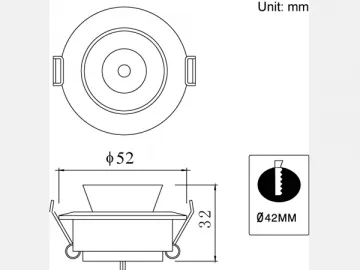

1W LED Ceiling Light

1W LED Ceiling Light

-

Curved Whirlpool Bathtub

Curved Whirlpool Bathtub

-

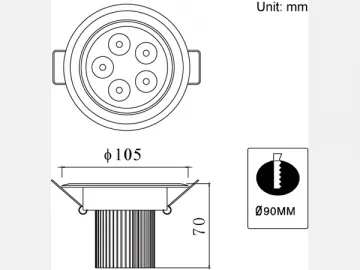

5W LED Ceiling Light

5W LED Ceiling Light

-

3W LED Ceiling Light

3W LED Ceiling Light

-

SJ60 PVC Heat Shrink Film Blowing Machine

SJ60 PVC Heat Shrink Film Blowing Machine

-

SJ65 PVC Heat Shrink Film Blowing Machine

SJ65 PVC Heat Shrink Film Blowing Machine