Core Shooter/ Core Shooting Machine

JDX's core shooting machines are designed with coated sand core shooting process, suitable for two core making processes, i.e. hot box and cold box. There are two guide columns for vertical parting, and two different sets of molds are equipped at the same time. The fixed frame at center position allows for installing molds from both sides. This core shooting machine is widely used in casting industry, the sand cores produced are featured by precise dimensions and smooth surfaces.

JDX's core shooting machines are designed with coated sand core shooting process, suitable for two core making processes, i.e. hot box and cold box. There are two guide columns for vertical parting, and two different sets of molds are equipped at the same time. The fixed frame at center position allows for installing molds from both sides. This core shooting machine is widely used in casting industry, the sand cores produced are featured by precise dimensions and smooth surfaces.

Specifications Model: Z954Standard die size: 520×400×180/200 (length×height×fixed mold thickness/moving mold thickness)

Sand core weight: 18 (kg)

Quantity of guide column: Two

Drive: Pneumatic

Turnover: 180°

Core shooting: Singles side/ Double side

Heating: Electric (20 kW)

Moving mold and sand barrel movements: Parallel

Control: PLC

Sand adding unit Model: Z954M

Standard die size: 520×400×180/200 (length×height×fixed mold thickness/moving mold thickness)

Sand core weight: 18 (kg)

Quantity of guide column: Two

Drive: Pneumatic

Turnover: 180°

Core shooting: Singles side/ Double side

Heating: Coal gas

Moving mold and sand barrel movements: Parallel

Control: PLC

Sand adding unit Model: Z956

Standard die size: 600×400×180/200 (length×height×fixed mold thickness/moving mold thickness)

Sand core weight: 18 (kg)

Quantity of guide column: Two

Drive: Pneumatic

Turnover: 180°

Core shooting: Singles side/ Double side

Heating: Electric (30 kW)

Moving mold and sand barrel movements: Parallel

Control: PLC

Sand adding unit Model: Z956C

Standard die size: 600×400×210/250 (length×height×fixed mold thickness/moving mold thickness)

Sand core weight: 25 (kg)

Quantity of guide column: Two

Drive: Pneumatic

Turnover: 180°

Core carriage

Core shooting: Singles side/ Double side

Heating: Electric (30 kW)

Moving mold and sand barrel movements: Parallel

Control: PLC

Sand adding unit Model: Z957

Standard die size: 700×410×200/220 (length×height×fixed mold thickness/moving mold thickness)

Sand core weight: 30 (kg)

Quantity of guide column: Two

Drive: Hydraulic

Turnover: 180°

Core carriage

Core shooting: Singles side/ Double side

Heating: Electric (40 kW)

Moving mold and sand barrel movements: Parallel

Control: PLC

Sand adding unit Model: Z957B

Standard die size: 700×550×200/280 (length×height×fixed mold thickness/moving mold thickness)

Sand core weight: 35 (kg)

Quantity of guide column: Two

Drive: Hydraulic

Turnover: 180°

Core carriage

Core shooting: Singles side/ Double side

Heating: Electric (40 kW)

Moving mold and sand barrel movements: Parallel

Control: PLC

Sand adding unit Model: Z958

Standard die size: 800×600×210/300 (length×height×fixed mold thickness/moving mold thickness)

Sand core weight: 40 (kg)

Quantity of guide column: Four

Drive: Hydraulic

Turnover: 180°

Core carriage

Core shooting: Singles side/ Double side

Heating: Electric (50 kW)

Moving mold and sand barrel movements: Parallel

Control: PLC

Sand adding unit Model: Z958B

Standard die size: 850×700×250/300 (length×height×fixed mold thickness/moving mold thickness)

Sand core weight: 50 (kg)

Quantity of guide column: Four

Drive: Hydraulic

Turnover: 180°

Core carriage

Core shooting: Singles side/ Double side

Heating: Electric (60 kW)

Moving mold and sand barrel movements: Parallel

Control: PLC

Sand adding unit Die Casting Machine Production Workshop Tags core making facilities metal casting machine automatic core making machine cold box core shooter hot box core shooter core blowing machine

Links:https://www.globefindpro.com/products/5726.html

-

Prepayment Energy Meter

Prepayment Energy Meter

-

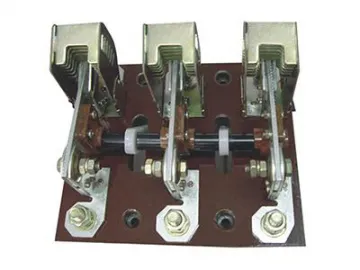

Knife Switch

Knife Switch

-

Electrostatic Oil Mist Collector

Electrostatic Oil Mist Collector

-

Pellet Mill, Pellet Press Biomass Pellets, Wood Pellets Production

Pellet Mill, Pellet Press Biomass Pellets, Wood Pellets Production

-

Drum Dryer, Rotary Dryer

Drum Dryer, Rotary Dryer

-

Top Mount Filter Cartridge

Top Mount Filter Cartridge

-

Single Phase Meter, Three Phase Meter

Single Phase Meter, Three Phase Meter

-

36Kv Instrument Transformer

36Kv Instrument Transformer

-

Discharge Coil

Discharge Coil

-

Indoor Disconnect switch

Indoor Disconnect switch

-

Self Amalgamating Tape

Self Amalgamating Tape

-

Cable Lug

Cable Lug