Corrective Device

Corrective Device

A. The structure of Automatic corrective devices

The devices with rational structure, the roller easy to Interchange, smallcorrection resistance reduce power consumption, reliable action, sensitivereflection long lasting automatic repeated corrective function work in harshenvironment, no malfunction, durability, easy to maintain, the belt always runin the middle.

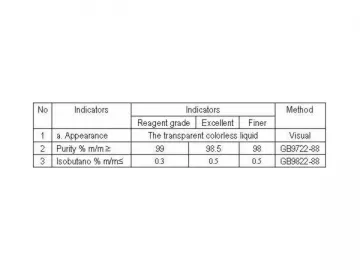

B. Main Specifications of Corrective Device

C. Main Parameters of Corrective Device

| Item | Units | Parameters |

| Applied speed | m/s | 0.6~3.5 |

| Inclination |

| 0~30o |

| Correction back Angle |

| ±30° |

| Correction scope | L | 0~120 |

| Mount torque transmission poles | N/m | 1~1.6 N/m |

| Precision of corrective | L | ±15 |

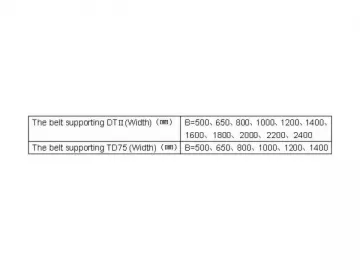

D. Corrective Device Install partitions and supportingvolume

The usual partition of ten rollers is 12m, every tenroller need a corrective device.

E. Please attend the details when you make an order according to the standardof DTandTD75 to set up the parameters and size of corrective devices. If yourorder is special, please give us your device parameters and size. In order toavoid the loss cause by false data, we offer mapping service.

F. About the Installation of Corrective Device

a. Installation of Corrective Device

1 Put roller and bracket at the place selected the bracket at the head of thedirection of the belt move.

2 Put the bracket into base then join bracket and linkage with peglast join linkage and lug with peg.

3 Adjust high of the linkage, lug and bracket, make them at the same high, thenlock the peg on bracket.

4 Peg the bracket (Use peg or welding

5 Install the roller and roller bracket, then lock it.

b. Debugging of Corrective Device

Startup the machine, make one side of rollers push the belt and the belt run onmiddle of crankshaft, then stop the machine and peg the bracket of roller, thenthe other side.

Notice:

1 Roller should keep 20mm higher than bracket

2 When Debugging the belt should run along axes, keep the bracket and roller havea right-angle.

3 Distance between two rollers is 10mm.

C. Operation of Corrective Device

1. The device always for one direction, install the main bracket at thedirection of roller run, subsidiary bracket at the reverse direction.

2. The roller on subsidiary bracket play a very important role of the device,the roller must keep 5-10mm to the belt, if it’s too near to belt that willdamage the roller and belt, if too far from the belt the device wills loss itsfunction.

Maintenance of Corrective Device

1. Inspect the device once a week.

2. Clean the dust once a week.

3. Get rid of rust and painting when inspecting the device.

4. Interchange the damaged components on time.

Links:https://www.globefindpro.com/products/57265.html