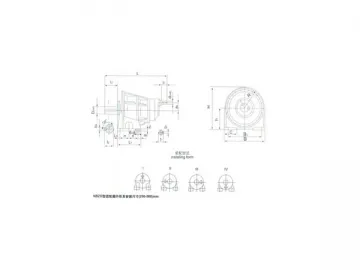

AC11 Gear Speed Reducer

Gear Speed Reducer is suitable for the transmission devicewith output shaft and input shaft laying verticality. This speed reducer wemanufactured in Chinais mainly applied on belt conveyer and some other transportation machines andit can also be used on other general mechanical transmission organs ofmetallurgy, mining, chemical, coal, construction material, textile, oil/petroleum and so on.

Introduction ofGear Speed Reducer

AC11 Gearbox is designed specially for plastic and rubber screw extruder. Itcomposed of high-precision gear and force-plate power transmission device. Themain character of series gearbox is high strength alloy steel that being usedfor gear and shaft parts. Gear goes through processes of gasification, quenching,and grinding. Its precision could meet GB10095-88, DIN 6. Hardness of gearsurface could be HRC54-62. A big size thrust bearing uses in the output part,which can bear axial shaft force of screw. The gearbox also boasts its compactdesign, high bearing load, smooth transmission, low noise and high efficiency.

Working Conditionsof Gear Speed Reducer

A. The high speed shaft should round no more than 1500rpm.

B. The circumferential velocity of gear should no more than 20m/s.

C. Working environment temperature is -40—45℃. Lubricant should be heated up to 0℃ if temperature lowers than 0℃.

D. Gearbox could be rounded in a clockwise and un-clockwise direction.

But for High speed shaft with single direction oil pump, its usual direction willbe output shaft clockwise when facing the output shaft. Please contact us ifotherwise.

Usage andMaintenance

1. Gearbox should avoid dampness during the transport and stock. It needspainting some rustproof oil if without using in half a year.

2. Gearbox should be mounted on smooth bases, the screw in the output shaftshould not be locked while re-rotating to avoid giving more loads on bearings.It is not allowed to disassemble shaft with force.

3. Oil should be added to the middle level of oil gauge and needs to be checkedfrequently to ensure oil level not lower than middle level. It needs to bechanged after first running 300-600hrs, and then change it every 3000hrs.Gearbox should stop being used, and drain heat oil out. Gearbox should bewashed clean by same quality oil.

4. Gearbox with force oil pump maybe have high noise when start because of thedensity of oil. This phenomenon will disappear when oil temperature increased.Gearbox with motor pump should be started for a while before loading.

5. If oil pump have abnormal noise when running, it maybe the problem of oilway. Please wash relative parts. And ensure that gearbox runs without loadingafter a long time stock or under low temperature conditions.

6. If oil temperature has a relative increase when running, e.g. It increasesto be 70℃ or evento be 100℃, oilquality will become worse and form abnormal noise. Under that situation pleasestop using to check the reason. It can only be used after removing problems.

Problemsand Resolve Method

| Problem | Reason | Method |

| abnormal noise | damage of gears’ engaging parts | check engaging parts, and change the broken ones |

| big interval of gears |

| |

| damage of bearing | adjust bearing interval; change damage bearing | |

| big noise of fixing part | fixing parts loose | fasten nut and thread; change damage parts |

| high temperature of bearing | low level of oil | add oil at normal temperature |

| decreased oil quality |

| |

| damaged bearing | check bearing, change if needed | |

| damaged oil pump | check oil pump, change if needed | |

| leakage | bad sealing | seal the part well |

| water in oil | foam in oil | check the water condition of oil by glass |

| check oil condition in chemical lab, wash and change if needed | ||

| increased working temperature | high oil level | check oil level and adjust |

| aging of oil | change oil if needed | |

| pollution of oil | ||

| damaged of oil pump | check function of oil pump, repair or change it |

Links:https://www.globefindpro.com/products/57542.html

-

ARE Double Stage Worm Reducer

ARE Double Stage Worm Reducer

-

Combination Worm Gear Units of Worm Reducer

Combination Worm Gear Units of Worm Reducer

-

AC3 Gear Speed Reducer

AC3 Gear Speed Reducer

-

ACDE Single Stage Worm Reducer

ACDE Single Stage Worm Reducer

-

British System Worm Gearbox

British System Worm Gearbox

-

AB8 Planetary Gearbox

AB8 Planetary Gearbox

-

AB7 Planetary Gearbox

AB7 Planetary Gearbox

-

Explosion-proof Three-phase Asynchronous Motor

Explosion-proof Three-phase Asynchronous Motor

-

Dimension Sheets-Overview

Dimension Sheets-Overview

-

Load Isolating Switch C Series

Load Isolating Switch C Series

-

Industrial Connectors LDE2431/LDE2441 /LDE2451

Industrial Connectors LDE2431/LDE2441 /LDE2451

-

ZGQ2CB-63 Automatic Transfer Switches (ATS)

ZGQ2CB-63 Automatic Transfer Switches (ATS)