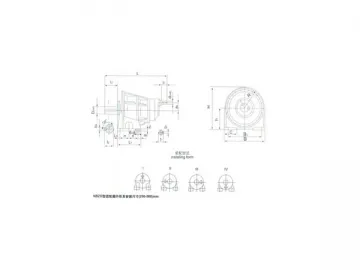

AC9 Gear Speed Reducer

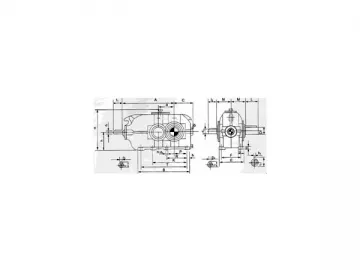

Cylindrical Bevel Gearbox (Right Angle Shaft Gearbox) isthe transmission that the output shaft locates verticality to the input shaft.The main parts use the high quality alloy steel. The gear go throughcarburization, hardening and grinding, DIN 6. It’s featured high bearing load,long life-span, compact volume, high efficiency and light weight and so on. Gear Speed Reducer which meets standards of No.JB/T9002-1999 is a new product.

Application Fieldof Gear Speed Reducer:

Gear Speed Reducer is suitable for the transmission device with output shaftand input shaft laying verticality. It is mainly applied to belt conveyer andsome other transportation machines and the speed reducer can also be used inother general mechanical transmission organs of metallurgy, mining, chemical,coal, construction material, textile, oil /petroleum and so on.

Working Conditionsof Gear Speed Reducer:

a. The maximum speed of input shaft should not be more than 1500s/min

b.The circumferential velocity of gears should not beover 20m/s

c. The working temperature of it can be -40~50℃.Lubricant should be heated up to10℃ before starting if the ambienttemperature below 0℃.

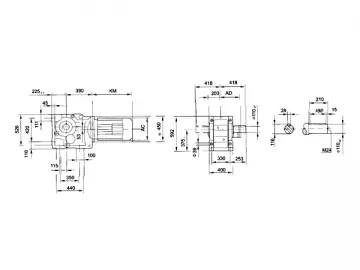

TechnicalParameters of Gear Speed Reducer:

| Center Distance a | d1 | I | d2 | l2 | D | L | A | B | C | E | F | G | S | h | H | M |

| 160 | 40 | 110 | 48 | 110 | 70 | 140 | 500 | 500 | 190 | 250 | 210 | 65 | 35 | 180 | 430 | 145 |

| 180 | 42 | 50 | 80 | 170 | 565 | 565 | 215 | 270 | 230 | 70 | 200 | 475 | 160 | |||

| 200 | 50 | 55 | 90 | 625 | 625 | 240 | 300 | 250 | 75 | 40 | 225 | 520 | 175 | |||

| 224 | 55 | 65 | 140 | 100 | 210 | 705 | 705 | 260 | 320 | 270 | 80 | 45 | 250 | 570 | 190 | |

| 250 | 60 | 140 | 75 | 110 | 785 | 785 | 290 | 370 | 310 | 90 | 50 | 280 | 626 | 210 | ||

| 280 | 65 | 85 | 170 | 120 | 875 | 875 | 325 | 400 | 340 | 100 | 55 | 315 | 702 | 230 | ||

| 315 | 75 | 95 | 140 | 250 | 975 | 975 | 355 | 450 | 380 | 110 | 60 | 355 | 809 | 260 | ||

| 355 | 90 | 170 | 100 | 210 | 160 | 300 | 1085 | 1085 | 390 | 480 | 410 | 120 | 65 | 400 | 900 | 285 |

| 400 | 100 | 110 | 170 | 1215 | 1215 | 440 | 530 | 460 | 130 | 70 | 450 | 970 | 305 | |||

| 450 | 110 | 210 | 130 | 250 | 190 | 350 | 1365 | 1365 | 490 | 600 | 510 | 140 | 80 | 500 | 1071 | 345 |

| 500 | 120 | 150 | 220 | 1525 | 1525 | 570 | 650 | 560 | 150 | 90 | 560 | 1210 | 435 | |||

| 560 | 130 | 250 | 160 | 300 | 250 | 410 | 1705 | 1705 | 610 | 750 | 640 | 160 | 100 | 630 | 1325 | 475 |

| Center Distance a | n-d3 | N | P | R | K | T | b1 | t1 | b2 | t2 | b3 | t3 | kg | oil | Code |

| 160 | 6-18 | 30 | 115 | 210 |

| 440 | 12 | 43 | 14 | 51.5 | 20 | 74.5 | 173 | 7 | 160.0 |

| 180 | 135 | 240 | 505 | 45 | 53.5 | 22 | 85 | 232 | 9 | 180.0 | |||||

| 200 | 6-23 | 35 | 145 | 255 | 555 | 14 | 53.5 | 16 | 59 | 25 | 95 | 305 | 13 | 200.0 | |

| 224 | 165 | 290 | 635 | 16 | 59 | 18 | 69 | 28 | 106 | 415 | 18 | 224.0 | |||

| 250 | 6-27 | 40 | 180 | 315 | 705 | 18 | 64 | 20 | 79.5 | 116 | 573 | 25 | 250.0 | ||

| 280 | 45 | 200 | 355 | 785 | 69 | 22 | 90 | 32 | 127 | 760 | 36 | 280.0 | |||

| 315 | 6-33 | 50 | 220 | 405 | 875 | 20 | 79.5 | 25 | 100 | 36 | 148 | 1020 | 51 | 315.0 | |

| 355 | 55 | 245 | 450 | 975 | 25 | 95 | 28 | 106 | 40 | 169 | 1436 | 69 | 355.0 | ||

| 400 | 280 | 510 | 1105 | 28 | 106 | 116 | 179 | 1966 | 95 | 400.0 | |||||

| 450 | 8-39 | 60 | 315 | 575 | 940 | 1245 | 116 | 32 | 137 | 45 | 200 | 2532 | 130 | 450.0 | |

| 500 | 70 | 350 | 645 | 1050 | 1385 | 32 | 127 | 36 | 158 | 50 | 231 | 3633 | 185 | 500.0 | |

| 560 | 8-45 | 80 | 390 | 715 | 1165 | 1545 | 137 | 40 | 169 | 56 | 262 | 5020 | 260 | 560.0 |

Links:https://www.globefindpro.com/products/57550.html

-

AC1 Gear Speed Reducer

AC1 Gear Speed Reducer

-

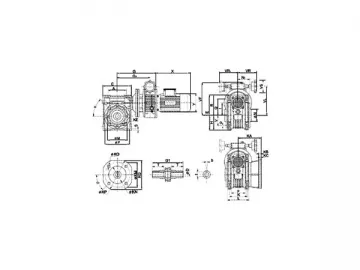

ABCC Series Double Stage Worm Reducer

ABCC Series Double Stage Worm Reducer

-

Stepless Worm Gearbox of Worm Reducer

Stepless Worm Gearbox of Worm Reducer

-

Single Standard Worm Reducer

Single Standard Worm Reducer

-

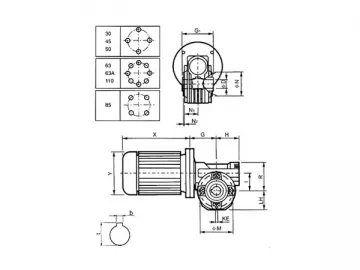

ACPK Single Stage Worm Reducer

ACPK Single Stage Worm Reducer

-

FB Motors

FB Motors

-

AC4 Gear Speed Reducer

AC4 Gear Speed Reducer

-

AB8 Planetary Gearbox

AB8 Planetary Gearbox

-

British System Worm Gearbox

British System Worm Gearbox

-

ACDE Single Stage Worm Reducer

ACDE Single Stage Worm Reducer

-

AC3 Gear Speed Reducer

AC3 Gear Speed Reducer

-

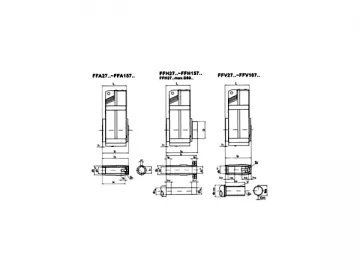

Combination Worm Gear Units of Worm Reducer

Combination Worm Gear Units of Worm Reducer