AC5 Gear Speed Reducer

AC5 Gear Speed Reducer applies full-range modularizationdesign with a low noise and high torque characteristics. Appropriatelubricating oil can improve the efficiency of steering machine and prolong therunning lives. The initial abrasion period should be two weeks or 100-200hours. During this process, there will be a few metal abrasive dusts in thespeed reducer. Please make sure the interior surface has been fully clearedout, and replace lubricating oil on time. While long time using, please changethe oil every half to one year or 1000-2000 hours. Meanwhile, gear speedreducer we manufactured is in accord with the quality standards of both Chinaand abroad.

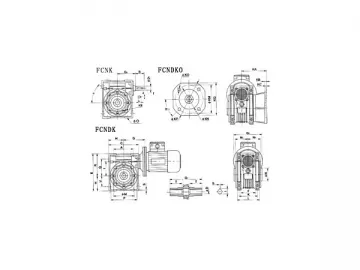

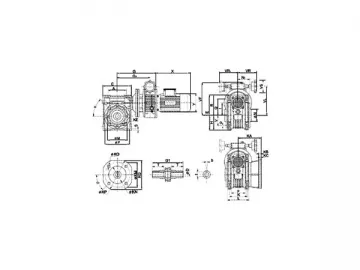

Bevel-angleGearbox

Bevel angle gear reducer is widely used in conveying, rubber and metallurgyindustries.

Size: T2-T5

Input power: 0.014-335kw

Ratio: 1:1, 1:1.5, 2:1, 2.5:1, 1:3, 4:1, 5:1

Rotation direction: Clockwise and Counter-Clockwise

Low noise and high load capacity

| T Series Weight Table | ||||||||||

| Type | T2 | T4 | T6 | T7 | T8 | T10 | T12 | T16 | T20 | T25 |

| m (kg) | 2 | 10 | 21 | 32 | 49 | 78 | 124 | 188 | 297 | 488 |

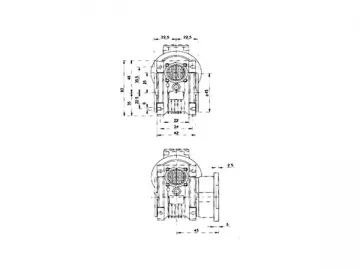

TechnicalParameters of Gear Speed Reducer:

|

| T2 | T4 | T6 | T7 | T8 | T10 | T12 | T16 | T20 | T25 |

| A1a | 48 100 | 53.5 155 | 81 190 | 88 210 | 110.5 235 | 120 285 | 130 340 | 150 390 | 195 490 | 235 580 |

| a0 b | 84 100 | 125 155 | 152 190 | 174 210 | 195 235 | 240 285 | 290 340 | 330 390 | 430 410 | 520 480 |

| b0c | 84 10 | 125 17 | 152 17 | 174 20 | 195 22 | 240 25 | 290 32 | 330 40 | 110 32 | 130 35 |

| D d(h7) | 58 15 | 76 19 | 115 25 | 125 32 | 152 40 | 155 45 | 168 50 | 193 60 | 275 72 | 299 85 |

| E e1(H8)*deep | 33 90×3 | 38 155×5 | 50 190×5 | 65 220×5 | 75 250×5 | 90 305×5 | 100 370×5 | 105 420×7 | 105 360×10 | 130 430×10 |

| f h | 5 52 | 2 76 | 17 90 | 13 100 | 18 115 | 10 140 | 0 75 | 10 200 | 10 245 | 10 290 |

| L L1 | 124 82 | 180 117.5 | 222 146 | 265 178 | 308 210.5 | 360 240 | 415 270 | 455 290 | 545 330 | 660 400 |

| L2L4 | 52 114 | 76 156 | 87 214 | 99 226 | 114.5 266 | 133 300 | 160 350 | 186 420 | 217 510 | 255 600 |

| LAB n | 0 4 | 360 4 | 444 4 | 530 4 | 616 4 | 720 4 | 830 4 | 4 | 8 | 8 |

| r s | 5 9 | 6 10.5 | 8 14 | 10 14 | 12 14 | 14 16 | 14 21 | 19 25 | 20 21 | 22 24 |

| t | 17 | 21.5 | 28 | 35 | 43 | 48.5 | 53.5 | 64 | 76.5 | 90 |

|

|

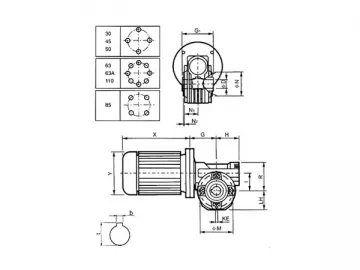

| T6 | T7 | T8 | T10 | T12 | T16 | T20 | T25 |

| 4:1 | d(h7) | 19 | 22 | 28 | 32 | 36 | 50 | 55 | 70 |

| E | 38 | 50 | 62 | 62 | 75 | 100 | 105 | 150 | |

| L | 210 | 265 | 310 | 362 | 415 | 465 | 560 | 660 | |

| L1 | 134 | 178 | 212.5 | 242 | 270 | 300 | 345 | 400 | |

| LAB | 420 | 530 | 620 | 724 | 830 |

|

|

| |

| r | 6 | 6 | 8 | 10 | 10 | 14 | 16 | 20 | |

| t | 2.5 | 24.5 | 31 | 35 | 39 | 53.5 | 59 | 74.5 | |

| 5:1 | d(h7) | 19 | 22 | 28 | 32 | 36 | 42 | 50 | 60 |

| E | 38 | 50 | 62 | 62 | 75 | 90 | 100 | 105 | |

| L | 210 | 265 | 310 | 362 | 415 | 465 | 555 | 670 | |

| L1 | 134 | 178 | 212.5 | 242 | 270 | 300 | 340 | 410 | |

| LAB | 420 | 530 | 620 | 724 | 830 |

|

|

| |

| r | 6 | 6 | 8 | 10 | 10 | 12 | 14 | 18 | |

| t | 2.5 | 24.5 | 31 | 35 | 39 | 45 | 53.5 | 64 |

Links:https://www.globefindpro.com/products/57559.html

-

AC6 Gear Speed Reducer

AC6 Gear Speed Reducer

-

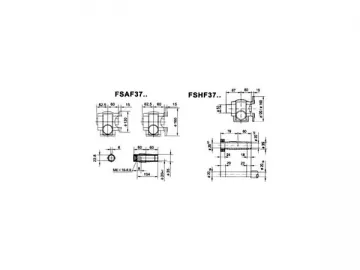

FS Motor

FS Motor

-

ACPA Single Stage Worm Reducer

ACPA Single Stage Worm Reducer

-

Electromagnetic Governor Motor

Electromagnetic Governor Motor

-

ABC Series Single Stage Worm Reducer

ABC Series Single Stage Worm Reducer

-

Heavy Leveller

Heavy Leveller

-

AC2 Gear Speed Reducer

AC2 Gear Speed Reducer

-

AGB Three-phase Asynchronous Motor

AGB Three-phase Asynchronous Motor

-

FB Motors

FB Motors

-

ACPK Single Stage Worm Reducer

ACPK Single Stage Worm Reducer

-

Single Standard Worm Reducer

Single Standard Worm Reducer

-

Stepless Worm Gearbox of Worm Reducer

Stepless Worm Gearbox of Worm Reducer