AQG Cycloidal Reducer

1. Wide arrange ratio of this cycloidal gearbox series: Single stage: 1/6~1/87 Double stage: 1/99~1/7569

2. Please contact us for more requirements of our cycloidal gearbox 8000 series.

3. High transmission efficiency of our cycloidal gearbox 8000 series is up to 99%

4. This cycloidal gearbox is characterized by small volume, compact design and the light weight features.

5. Long life-span, smooth driving, stable performance, low noise, and front-to-back running directions

6. High load capacity and the little inertia moment of this cycloidal gearbox make it suitable for frequent start-up.

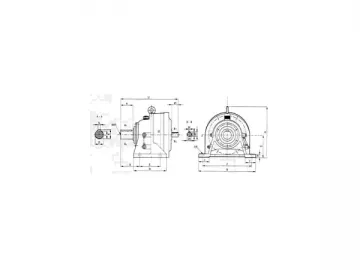

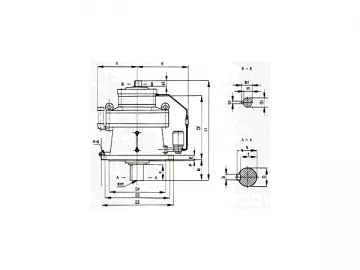

Technical Parameters of BLXL Cycloidal Reducer 8000 Series:

| SizeType | L1 | P | E | M | n-d | D2 | D3 | D4 | Input | Output | Weight | |||||||||

| D1 | e1 | b1 | h1 | t1 | D | e | b | h | t | sxm | ||||||||||

| 8075 | 145 | 3 | 8 | 34 | 6-9 | 120 | 102 | 80 | 12 | 25 | 4 | 13.5 | 9.5 | 14 | 25 | 5 | 16 | 11 | — | 3.5 |

| 8085 | 151 | 3 | 9 | 42 | 160 | 134 | 110 | 12 | 25 | 4 | 13.5 | 9.5 | 18 | 30 | 6 | 20.5 | 14.5 | — | 4.5 | |

| 8095 | 202 | 3 | 9 | 48 | 160 | 134 | 110 | 15 | 25 | 5 | 17 | 12 | 28 | 35 | 8 | 31 | 24 | — | 9 | |

| 8105 | 208 | 3 | 9 | 48 | 160 | 134 | 110 | 15 | 25 | 5 | 17 | 12 | 28 | 35 | 8 | 31 | 24 | — | 11 | |

| 8115 | 259 | 4 | 13 | 69 | 210 | 180 | 140 | 18 | 35 | 6 | 20.5 | 14.5 | 38 | 55 | 10 | 41 | 33 | — | 23 | |

| 8125 | 259 | 4 | 13 | 69 | 210 | 180 | 140 | 18 | 35 | 6 | 20.5 | 14.5 | 38 | 55 | 10 | 41 | 33 | — | 23 | |

| 8130 | 321 | 4 | 15 | 76 | 260 | 230 | 200 | 22 | 40 | 6 | 24.5 | 18.5 | 50 | 61 | 14 | 53.5 | 44.5 | M10X18 | 42 | |

| 8135 | 321 | 4 | 15 | 76 | 260 | 230 | 200 | 22 | 40 | 6 | 24.5 | 18.5 | 50 | 61 | 14 | 53.5 | 44.5 | M10X18 | 42 | |

| 8145 | 341 | 4 | 15 | 96 | 260 | 230 | 200 | 22 | 40 | 6 | 24.5 | 18.5 | 50 | 81 | 14 | 53.5 | 44.5 | M10X18 | 43 | |

| 8155 | 341 | 4 | 15 | 96 | 260 | 230 | 200 | 22 | 40 | 6 | 24.5 | 18.5 | 50 | 81 | 14 | 53.5 | 44.5 | M10X18 | 43 | |

| SizeType | L1 | P | E | M | n-d | D2 | D3 | D4 | K | W | Input | Output | Weight | ||||||||||||||||||||||||

| D1 | e1 | b1 | h1 | t1 | D | e | b | h | t | sxm | |||||||||||||||||||||||||||

| 8160 | 413 | 4 | 20 | 89 | 6-11 | 340 | 310 | 270 | 217 | 200 | 30 | 45 | 8 | 33 | 26 | 60 | 80 | 18 | 64 | 53 | M10X18 | 79 | |||||||||||||||

| 8165 | 413 | 4 | 20 | 89 | 6-11 | 340 | 310 | 270 | 217 | 200 | 30 | 45 | 8 | 33 | 26 | 60 | 80 | 18 | 64 | 53 | M10X18 | 79 | |||||||||||||||

| 8170 | 477 | 5 | 22 | 94 | 8-14 | 400 | 360 | 316 | 222 | 225 | 35 | 55 | 10 | 38 | 30 | 70 | 84 | 20 | 74.5 | 62.5 | M12X24 | 121 | |||||||||||||||

| 8175 | 477 | 5 | 22 | 94 | 8-14 | 400 | 360 | 316 | 222 | 225 | 35 | 55 | 10 | 38 | 30 | 70 | 84 | 20 | 74.5 | 62.5 | M12X24 | 121 | |||||||||||||||

| 8180 | 527 | 5 | 22 | 110 | 8-18 | 430 | 390 | 345 | 237 | 240 | 40 | 65 | 12 | 43 | 35 | 80 | 100 | 22 | 85 | 71 | M12X24 | 150 | |||||||||||||||

| 8185 | 527 | 5 | 22 | 110 | 8-18 | 430 | 390 | 345 | 237 | 240 | 40 | 65 | 12 | 43 | 35 | 80 | 100 | 22 | 85 | 71 | M12X24 | 150 | |||||||||||||||

Note: Matching tolerance of shaft d1/d2 is h6

Scan QR to Read

Links:https://www.globefindpro.com/products/57617.html

Links:https://www.globefindpro.com/products/57617.html

Recommended Products

-

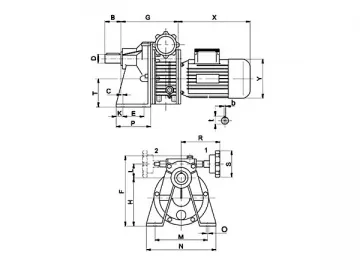

Horizontal Two Shaft Type Planetary Gearbox

Horizontal Two Shaft Type Planetary Gearbox

-

AC Drive Inverter

AC Drive Inverter

-

AS1 Stepless Variator

AS1 Stepless Variator

-

AS2 Stepless Variator

AS2 Stepless Variator

-

AQC Single Stage Cycloidal Reducer

AQC Single Stage Cycloidal Reducer

-

AQI Cycloidal Reducer

AQI Cycloidal Reducer

-

ARA Single Stage Worm Reducer

ARA Single Stage Worm Reducer

-

ARC Single Stage Worm Reducer

ARC Single Stage Worm Reducer

-

AQF Cycloidal Reducer

AQF Cycloidal Reducer

-

AB1 Planetary Gearbox

AB1 Planetary Gearbox

-

AS4 Stepless Variator

AS4 Stepless Variator

-

CNC Router Machine Parts

CNC Router Machine Parts

Hot Products