Purlin Forming Machine

Purlin FormingMachine

Features

C/Z shape purlins, made by our purlin forming machine, have excellentanti-bending property and are easy to install. They are widely used as the supporter for roofs and walls in large-scaleand mid scale construction, i.e., factories, warehouses, garages, exhibitioncenters, cinemas, theatres, gardens, etc.

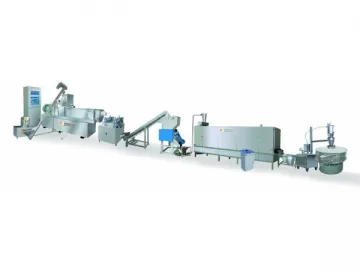

Machine Components

| Guiding Table | 1 set |

| Manual Decoiler | 1 set |

| Main Forming Machine | 1 set |

| PLC control System | 1 set |

| Hydraulic Cutting Station | 1 set |

| Punching Device | 1 set |

| Output Table | 1 set |

Technical Specifications

| Item | Description |

| Material Width | 150mm -450mm |

| Material Thickness | 2mm-3mm |

| Model | 80-300 |

| Yield Stress | 235Mpa |

| Material of Roller | Cr12 or bearing steel |

| Diameter of Shaft | 80mm |

| Voltage | AC380v/50hz or per customer’s requirement |

| Motor Power | 11kw-15kw |

| Hydraulic Power | 4-5.5kw |

| Stand | 13-18 |

| Control System | Mitsubishi PLC frequency conversion |

| Hydraulic Cutting Material | Cr12 heat treatment |

| Speed | 8-10m/min |

| Decoiler | 5 tons manual or hydraulic |

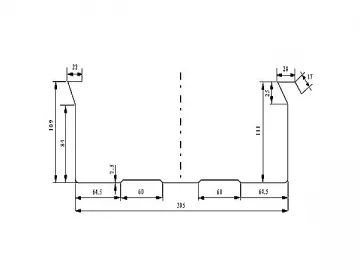

Technical Specifications C shape 80-300

| Item | Description |

| Material Width: | 150mm -450mm |

| Material Thickness | 1.5mm-3mm |

| Model | 80-300 |

| Yield Stress | 235-300Mpa |

| Material of Roller | Cr12 or Gcr15 |

| Diameter of Shaft | 80mm |

| Voltage | AC380v/50hz or per customer’s requirement |

| Motor Power | 15kw |

| Hydraulic Power | 15kw |

| Stand | 18 |

| Control System | Mitsubishi PLC frequency conversion |

| Hydraulic Cutting Material | Cr12 heat treatment |

| Speed | 8-10m/min |

| Decoiler | 5 tons manual or hydraulic |

Technical Specification C shape 80-200

| Item | Description |

| Material Width: | 150mm -450mm |

| Material Thickness | 1.5mm-3mm |

| Model | 80-200 |

| Yield Stress | 235-300Mpa |

| Material of Roller | Cr12 or Gcr15 |

| Diameter of Shaft | 80mm |

| Voltage | AC380v/50hz or per customer’s requirement |

| Motor Power | 11kw |

| Hydraulic Power | 15kw |

| Stand | 15 |

| Control System | Mitsubishi PLC frequency conversion |

| Hydraulic Cutting Material | Cr12 heat treatment |

| Speed | 8-10m/min |

| Decoiler | 5 tons manual or hydraulic |

Z Shape Purlin FormingMachine

| Item | Description |

| Material Width: | 150mm -450mm |

| Material Thickness | 1.5mm-3mm |

| Model | 80-300 |

| Yield Stress | 235Mpa |

| Material of Roller | Cr12 or Gcr15 |

| Diameter of Shaft | 100mm |

| Voltage | AC380v/50hz or per customer’s requirement |

| Motor Power | 18.5kw |

| Hydraulic Power | 15kw |

| Stand | 18 |

| Control System | Mitsubishi PLC frequency conversion |

| Hydraulic Cutting Material | Cr12 heat treatment |

| Speed | 8-10m/min |

| Decoiler | 5 tons manual or hydraulic |

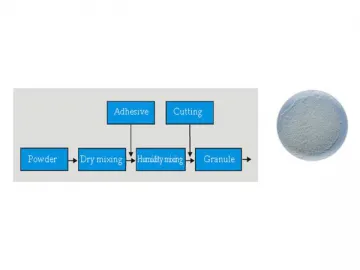

Flow Chart

Decoiling the sheet---Guiding thesheet---Leveling the sheet---Roll forming---Punching the sheet---Measuring thelength---Cutting the sheet---on the output table

Placement and Operator

The purlin forming machine should be placed on an even cement floor and lifted bya lifting device with a lifting capacity not less than five tons. It requires the space for storing materialsand laying the machine and the operation of the machine. The forming machine requires one operator andone porter. The temperature in the workspaceshould be no less than -14℃.

Our company is a purlin forming machine manufacturerbased in China. We specialize in a great variety of rollforming machines and metal sheet forming machines.

Located in Botou City,we at Haide Machinery Manufacturing Company areprovided with convenient transportation by not only water, but also land andair. The abundant raw materials andlabor forces here can help reduce our production costs. If you are interested in our purlin forming machine or other forming equipment, pleasedo not hesitate to contact us. We are fully confident that our products willmeet your needs.

Links:https://www.globefindpro.com/products/58275.html

-

Super Mixing Granulator

Super Mixing Granulator

-

(5) Downspout / Gutter Forming Machine

(5) Downspout / Gutter Forming Machine

-

(2) Roll Forming Machine H Series

(2) Roll Forming Machine H Series

-

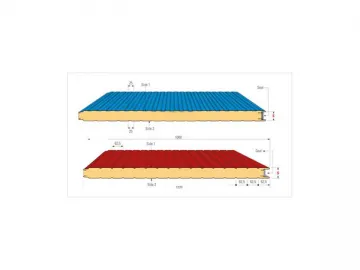

(1) Sandwich Panel Production Line

(1) Sandwich Panel Production Line

-

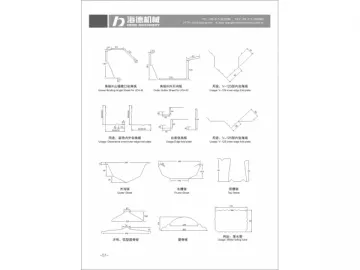

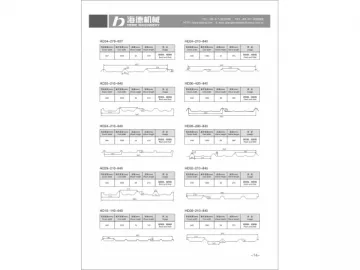

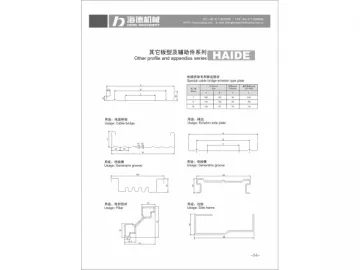

(五) Forming Machine Accessories

(五) Forming Machine Accessories

-

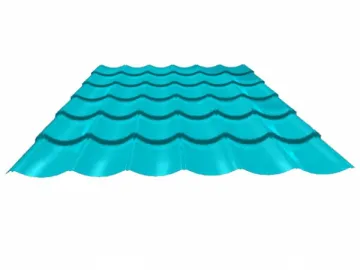

(1) HD120 Curved Roofing Sheet Roll Forming Machine

(1) HD120 Curved Roofing Sheet Roll Forming Machine

-

(3) Wall Panel Forming Machine

(3) Wall Panel Forming Machine

-

(6) Highway Guardrail Forming Machine

(6) Highway Guardrail Forming Machine

-

Bread Crumb Processing Line

Bread Crumb Processing Line

-

(2) Concealed Roof Panel Forming Machine

(2) Concealed Roof Panel Forming Machine

-

Potato Pellet Processing Line

Potato Pellet Processing Line

-

(6) Ridge Cap Forming Machine

(6) Ridge Cap Forming Machine