Vacuum Mixing Mulser

Vacuum Mixing Mulser

Characteristics

1. The main boiler adopts the coaxial triplex mixer to simplify thedrive mechanism, reduce the sealing links and save the time of installation.

2. High isotropic rotate speed:0-3500 r/min, lowmixing rotates speed: 0- 65 r/min. The vacuum mixing mulseradopts the step less frequency speed regulation, and the two mixing time can beset.

3. The homogenizer takes the foreign advanced technology. Isotropic effect isvery good. The emulsification can reach the ideal effect within ten minutes.

4. The main boiler is equipped with the CIP cleaning system. The contact partof material and container is made of the SUS316L imported high-quality material. The interfacecontacting with the material adopts the mirror polish. The roughness attainsthe sanitary 300 EMSH.

Application

Especially for the material has high matrix viscosity and solid content, the vacuummixing mulser is suitable for emulsification of thepharmaceuticals, cosmetic, fine chemical products.

Main Technical Parameters

| Model | Effective Capacity | Emulsify | Agitator | Outside Dimension | |||||

| Kw | r/min | Kw | r/min | L | W | H | MH | ||

| D1 | 100 | 3 | 0-3500 | 1.5 | 0-70 | 2800 | 2150 | 2100 | 2800 |

| D2 | 150 | 4 | 0-3500 | 1.5 | 0-70 | 2850 | 2150 | 2150 | 2900 |

| D3 | 200 | 4 | 0-3500 | 1.5 | 0-70 | 3000 | 2200 | 2200 | 3100 |

| D4 | 350 | 5.5 | 0-3500 | 2.2 | 0-70 | 3650 | 2650 | 2550 | 3600 |

Links:https://www.globefindpro.com/products/58286.html

-

(4) Roller Shutter Door Forming Machine

(4) Roller Shutter Door Forming Machine

-

Glazed Tile Forming Machine

Glazed Tile Forming Machine

-

(4) Tile Forming Machine

(4) Tile Forming Machine

-

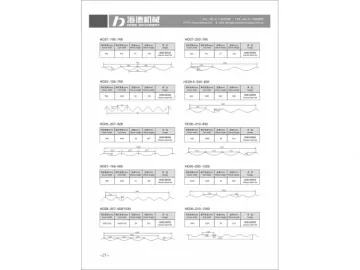

(5) Corrugated Sheet Forming Machine

(5) Corrugated Sheet Forming Machine

-

Automatic Unscrambler (Stacker)

Automatic Unscrambler (Stacker)

-

Poly-directional Movable Mixing Machine

Poly-directional Movable Mixing Machine

-

Aluminum Foil Strip Packing Machine

Aluminum Foil Strip Packing Machine

-

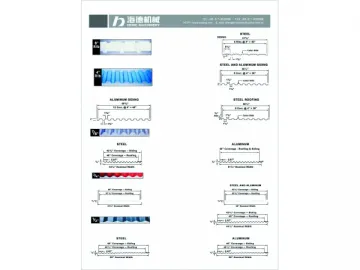

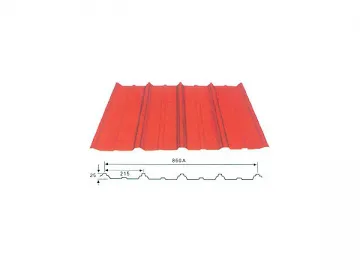

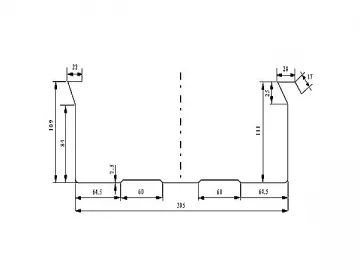

(2) Roof Panel Forming Machine

(2) Roof Panel Forming Machine

-

(2) Concealed Roof Panel Forming Machine

(2) Concealed Roof Panel Forming Machine

-

(1) HD120 Curved Roofing Sheet Roll Forming Machine

(1) HD120 Curved Roofing Sheet Roll Forming Machine

-

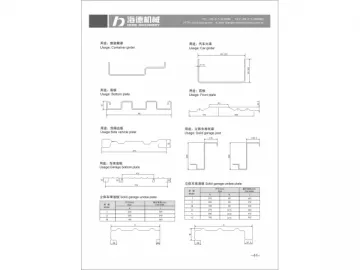

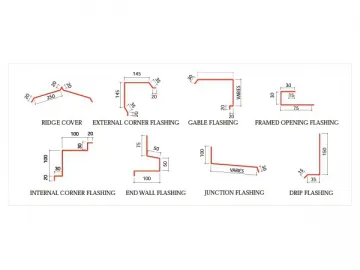

(五) Forming Machine Accessories

(五) Forming Machine Accessories

-

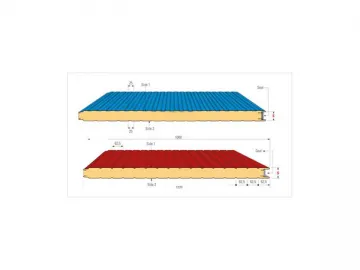

(1) Sandwich Panel Production Line

(1) Sandwich Panel Production Line