Poly-directional Movable Mixing Machine

Poly-directional Movable Mixing Machine

As one kind of new-type high effective mixing equipment, poly-directionalmovable mixing machine is elaborately designed, developed and manufactured byour company through adopting the advanced technology both at local and abroadinstead of traditional two-dimensional movable mixer, with an advantage of highmixing uniformity. Even for particles and powdery materials with differenttemperature, softness and specific gravity, the mixing machine can still be ingood operation. Poly-directional movable mixing machine conforms to "GMP'requirements. And its safety can be well guaranteed due to newly-developedseparation device and remote control device. In addition, all parts contactedwith material are made of imported stainless steel.

Characteristics

1. Featuring distinctive design, reasonable manufacture, lower noise,high uniform, mirror polished drum wall, full mixing, no cross contamination,and good appearance in design, it is also easy to fully clean, charge anddischarge.

2. Based on the three-dimensional motion, Poly-directional movable mixingmachine has particular function in motion. Delivering easy instillation andmaintenance, long life service, low height, small rotation space, highcoefficient of charging, especially it is possible to be placed in any buildingand the coefficient of charging dry particles reaches 85%.

3. During operation, all materials of the mixing drum can be in self-rotationand diffusion under both rotations without centrifugal force and being free ofsuch phenomenon as gravity, segregation, separation and accumulation.

4. High safety is one of its characteristics. If necessary, a radio remoteoperation system can be equipped to meet the requirement of our users.

5. The rocker is cast iron, firm and not to be out of shape. Its passive shaftis equipped with automatic adjustment device, which can dispel the torsionforce when working.

6. It has both functions of frequency control and constant speed control. Andthe specially -designed butterfly valve features high tightness, free leakage.

Application

Poly-directional movable mixing machine is widely used for unit operation ofdifferent materials in such industries as pharmaceutical industry, chemicalindustry and food industry etc.

Main Technical Parameters

| Specification | Mixing drum (l) | Max. load (l) | Motor power (kw) | Pevolution (r/min) | Weight(kg) | Height of material out let | Height of charger outlet | Overall size(mm) |

| A1 | 5 | 4 | 0.55 | ≤22 | 90 | / | 650 | 1010×670×670mm |

| A2 | 25 | 20 | 0.75 | ≤22 | 100 | 260 | 820 | 1010×670×670mm |

| A3 | 50 | 40 | 1.5 | ≤16 | 200 | 500 | 1200 | 1190×1090×1450mm |

| A4 | 100 | 80 | 2.2 | ≤15 | 500 | 600 | 1570 | 1580×1260×1600mm |

| A5 | 200 | 170 | 2.2 | ≤14 | 700 | 600 | 1680 | 1920×1550×1920mm |

| A6 | 400 | 340 | 4 | ≤13 | 1200 | 630 | 2080 | 2270×1670×2170mm |

| A7 | 600 | 500 | 5.5 | ≤13 | 1500 | 630 | 2350 | 2470×1860×2270mm |

| A8 | 800 | 680 | 7.5 | ≤10 | 2500 | 780 | 2600 | 2840×2200×2470mm |

| A9 | 1000 | 850 | 7.5 | ≤10 | 2600 | 700 | 2690 | 2950×2150×2530mm |

| A10 | 1500 | 1250 | 11 | ≤8 | 3000 | 850 | 3200 | 3403×2700×3120mm |

Links:https://www.globefindpro.com/products/58292.html

-

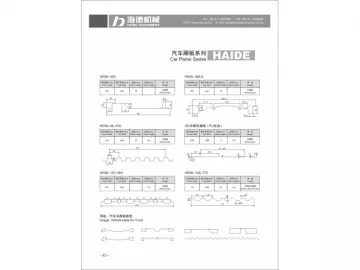

(四) Curved Roofing Sheet Roll Forming Machine

(四) Curved Roofing Sheet Roll Forming Machine

-

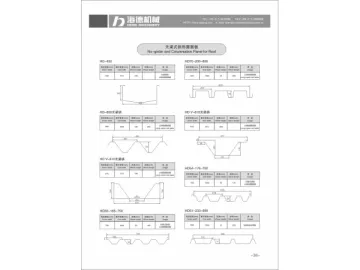

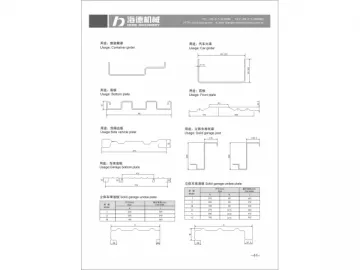

(1) Floor Decking Forming Machine

(1) Floor Decking Forming Machine

-

Inter-heating Soft-tube Automatic Filling Sealing Machine

Inter-heating Soft-tube Automatic Filling Sealing Machine

-

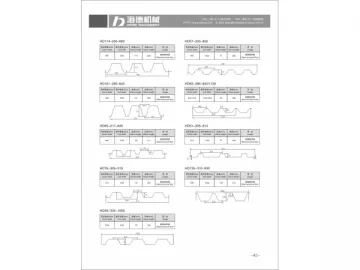

(3) Purlin Forming Machine

(3) Purlin Forming Machine

-

(3) Glazed Tile Forming Machine

(3) Glazed Tile Forming Machine

-

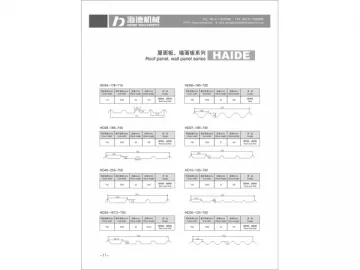

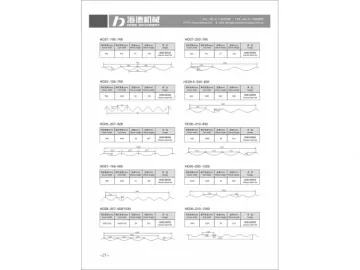

(2) Roof Panel Forming Machine

(2) Roof Panel Forming Machine

-

Automatic Unscrambler (Stacker)

Automatic Unscrambler (Stacker)

-

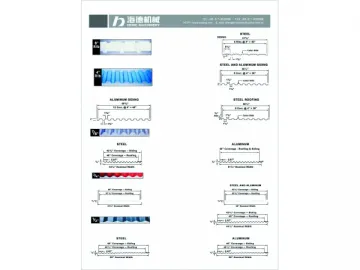

(5) Corrugated Sheet Forming Machine

(5) Corrugated Sheet Forming Machine

-

(4) Tile Forming Machine

(4) Tile Forming Machine

-

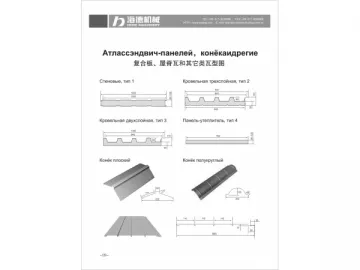

Glazed Tile Forming Machine

Glazed Tile Forming Machine

-

(4) Roller Shutter Door Forming Machine

(4) Roller Shutter Door Forming Machine

-

Vacuum Mixing Mulser

Vacuum Mixing Mulser