High Efficiency Boiling Drier

High efficiency boiling drier has quick drying speed anduniform temperature. In general, the drying time of each batch is about 20-30minutes. There is stirring device in the container, avoiding the joining of wetmaterials and the forming of agglomeration during the drying course, which canmake the materials dry evenly and swiftly.

Characteristics

1. High efficiency boiling drier adopts gasbag-style airtight in itsmaterial container.

2. The fluid-bed is round structure, so it can avoid dead corner.

3. The cloth bag filter at top is made from special anti-static fiber. Theoperation is safe.

4. High efficiency boiling drier is operated at sealed negative pressure anddesigned by GMP normal.

Application

High efficiency boiling drier is suitable for drying damp granule or powdermaterial in many fields, such as pharmaceutical industry, chemical industry,feed stuff industry, light industry to name a few. It is applicable to dryingbig granule, small mass, viscosity, black material produced by HLSG damp methodmixer gratulatory, giant arum, acrylic acid amide, etc. Those materials havebig volume change.

Main Technical Parameters

| Model Item | C1 | C2 | C3 | C4 | C5 | C6 |

| Volume(L) | 200 | 400 | 500 | 650 | 1000 | 1500 |

| Capacity(Kg) | 60 | 120 | 150 | 200 | 300 | 500 |

| Power of Fan (Kw) | 7.5 | 11 | 15 | 22 | 30 | 37 |

| Power of Stirring(Kw) | 0.55 | 1.1 | 1.1 | 1.1 | 1.1 | 1.5 |

| Speed of Stirring(r/min) | 11 | 11 | 11 | 11 | 11 | 11 |

| Steam Consumption(Kg/h) | 140 | 170 | 240 | 282 | 366 | 460 |

| Steam Pressure(mpa) | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Compressed Air Pressure | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Compressed Air Consumption | 0.6 | 0.6 | 0.9 | 0.9 | 1.2 | 1.2 |

| Dimensions Of Min Machine | 2750×1160 ×1420mm | 3070×1520 ×1520mm | 3320×1520 ×1820mm | 3200×1750 ×3100mm | 3300×1800×3100mm | 3500×1850×3200mm |

| Weight Of Main Machine(kg) | 1000 | 1450 | 1500 | 1700 | 1800 | 1900 |

Links:https://www.globefindpro.com/products/58302.html

-

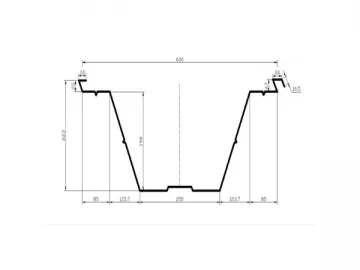

(2) HD240 Curved Roofing Sheet Roll Forming Machine

(2) HD240 Curved Roofing Sheet Roll Forming Machine

-

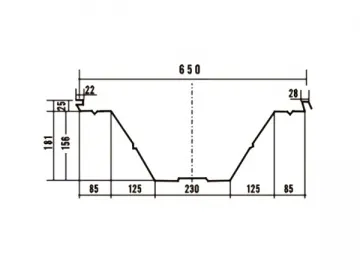

(1) Roll Forming Machine C Series

(1) Roll Forming Machine C Series

-

Automatic High Speed Cap Screwing Machine

Automatic High Speed Cap Screwing Machine

-

Semi-Automatic Capsule Filling Machine CF-1

Semi-Automatic Capsule Filling Machine CF-1

-

HLS180 Concrete Mixing Plant

HLS180 Concrete Mixing Plant

-

Buddha Sculpture, Buddha Statue

Buddha Sculpture, Buddha Statue

-

(1) Roll Forming Machine C Series

(1) Roll Forming Machine C Series

-

HD240 Curved Roofing Sheet Roll Forming Machine

HD240 Curved Roofing Sheet Roll Forming Machine

-

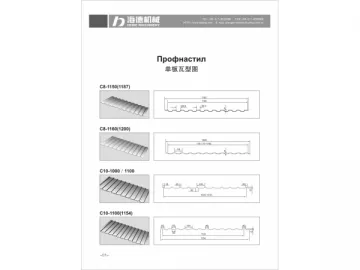

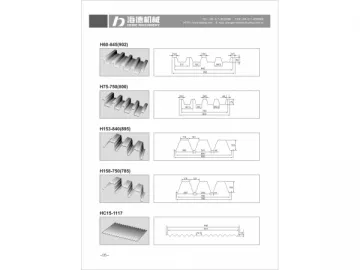

(2) Roll Forming Machine H Series

(2) Roll Forming Machine H Series

-

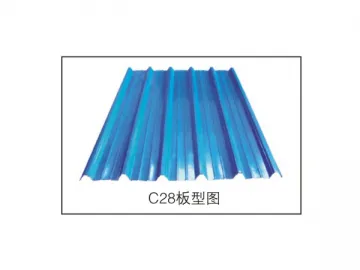

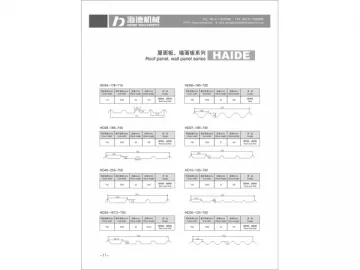

(2) Roof Panel Forming Machine

(2) Roof Panel Forming Machine

-

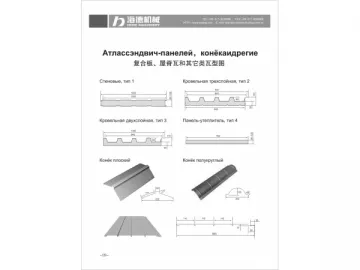

(3) Glazed Tile Forming Machine

(3) Glazed Tile Forming Machine

-

(3) Purlin Forming Machine

(3) Purlin Forming Machine