Granule Four-Side Sealing and Double Line Packing Machine

Granule four-side sealing and double line packing machineis precise in measurement and able to fill material at high temperatures. Beingapplicable to a wide range of uses, it is suitable for all complex film packingmaterials.

Characteristics

1) Two-step roller and four-side sealing, both fast and stable, with lownoise, firm sealing, reliably airtight, efficient packing and bags comingsmoothly.

2) A famed frequency changer is used for step less speed regulation and thesealing temperature is regulated by an intelligent temperature control. It canperform reliably, and is convenient to operate.

3) Photoelectric tracking system is used to ensure the automatic correcting ofdouble faced printing designs on the packing bags, precise counting.

4) Liquid crystal touch screen display is used to affect a graphical userinterface.

5) Granule four-side sealing and double line packing machine can do step lessadjustment for pouch length and width, suitable for packing medium dosages

Application

Granule four-side sealing and double line packing machine is suitable forpacking loose, non-sticky granule materials in the pharmacy, food, and chemicalindustries. Pack-able products include pellets, monosodium glutamate, sugar, oatmeal, seeds, coffee, and cold instant drink powder.

Main Technical Parameters

| Bag length | 50-150mm(L) adjustable |

| Bag width | 50-85mm(W) |

| Packing speed | 60-100 bags/min depend on punch size and material |

| Measuring range | 1-150ml |

| Cutting fashion | Flat cutting, with tear notch |

| Sealing fashion | 4 side sealing |

| Applicable film | PET/AL/PE PET/PE NY/AL/PE NY/PE |

| Max width of film roll | 350mm |

| Max film roll diameter | Φ300mm |

| Film roll core diameter | Φ70-76 mm |

| Power voltage | 220V/ single phase 50HZ |

| Power | 5.5KW |

| Package size | (L)1400mm×(W)1000mm×(H)1700mm |

| G.W | 650KG |

Links:https://www.globefindpro.com/products/58317.html

-

Transistorized Aluminum Foil Sealing Machine

Transistorized Aluminum Foil Sealing Machine

-

Carton Packing Line

Carton Packing Line

-

Other Animal Sculpture

Other Animal Sculpture

-

LED Indoor Light

LED Indoor Light

-

HLS120 Concrete Mixing Plant

HLS120 Concrete Mixing Plant

-

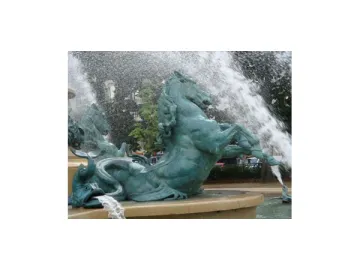

Bronze Horse Sculpture

Bronze Horse Sculpture

-

Al-Al, Al-Plastic Blister Packing Machine BP-2

Al-Al, Al-Plastic Blister Packing Machine BP-2

-

High-efficiency Intelligent Film Coating Machine

High-efficiency Intelligent Film Coating Machine

-

Bronze Dragon Sculpture

Bronze Dragon Sculpture

-

Concrete Batching Plant

Concrete Batching Plant

-

Street Lighting Pole

Street Lighting Pole

-

Electronic Tablet and Capsule Counting Machine

Electronic Tablet and Capsule Counting Machine