Al-Plastic-Al Blister Packaging Machine BP-4

The Al-Plastic-Al blister packaging machine can be separately packaged to enter2.2m elevators and renovateclean workshops. Main motor adopts frequency speed regulation: it can setcorresponding punch times according to range of stroke, easy and hard offeeding; Modularization of working stations design achieves the digital controlwhen adjusting working stations, and specially adds one independent perforationworking station to meet the diversified requirement of perforation pattern, andmeanwhile assures the definition of perforation and printing batch number.

Characteristics

1. All the parts contacting medicines are made of stainless steel andinnocuous material, complying to “GMP” requirement.

2. Adopting high quality of Al product integral guide rail, independentdesigned mould, the Al-Plastic-Al blister packaging machine is easy to assembleand disassemble pressing plate.

3. The design of impending type operation flat delivers the safety andconvenience of maintaining and cleaning machine.

4. The manipulator grip feeding mechanism adopts precision silk pole drive andis controlled by servo motor, with steady running and synchronization accuracy.The length of stroke can be designed as per customers’ specific blister sheetrequirement. It can be adjusted through PLC control panel.

Main Technical Parameters

| Max. Punch Speed | AL/PL:50 times/min | |

| AL/PL/AL:35 times/min | ||

| Max. Production Capacity | AL/PL:35 thous./h | |

| AL/PL/AL:15 thous./h | ||

| Adjustable range of stroke | Standard dispose≤160mm(design according to the requirement of the customer) | |

| Max. Forming Area | 245×112mm | |

| Max. Forming Depth | AL/PL:14mm | |

| AL/PL/AL:14mm | ||

| Specification of packing material | Note: the depth of the packing material 130-260mm | Medicinal PVC:260×0.25(0.15-0.5)mm |

| Sealing PTP:260×0.02mm | ||

| Power connection | Three Phases Four Wires : 380V 50Hz (220V 60Hz) | |

| Total power | 7.6 KW | |

| Main Motor Power | 2.2 KW | |

| The Power of Heat-sealing for Upper and Lower Forming | 1.5 KW(×2) | |

| The power of Heat-sealing | 1.2 KW(×2) | |

| Air Pump(Air Compressor) Volume | ≥0.38m3/min | |

| Dimension of overall machine | 4500×720×1650mm | |

| Dimension of separate packing cases | 2300×880×1800mm×2 | |

| Weight | 2200kg | |

Configuration

| No | Name | Manufacturer | Place | Qty |

| 1 | Touch Screen | Japan Digital | Taiwan | 1 |

| 2 | PLC | Siemens | Germany | 1 |

| 3 | Extend Die Block | Siemens | Germany | 1 |

| 4 | Temperature Die Block | Siemens | Germany | 1 |

| 5 | Circuit Breaker | Siemens | Germany | 1 |

| 6 | Circuit Breaker | Siemens | Germany | 3 |

| 7 | Circuit Breaker | Siemens | Germany | 1 |

| 8 | Frequency Converter | Danfoss | Danmark | 1 |

| 9 | AC Contactor | Schneider | France | 3 |

| 10 | Emergency Stop Button | Schneider | France | 1 |

| 11 | Switch Power | Mingwei | Taiwan | 1 |

| 12 | Relay | Omron | Japan | 2 |

| 13 | Proximity Switch | Omron | Japan | 1 |

| 14 | Motor |

|

| 1 |

| 15 | Electromagnetic Valve | SMC | Japan | 4 |

| 16 | Control Valve | SMC | Japan | 2 |

| 17 | Control Valve | SMC | Japan | 1 |

| 18 | Double Reductor Valve | SMC | Japan | 1 |

| 19 | Servo Switch Power | Mingewei | Taiwan | 2 |

| 20 | Servo Controller | Germany KINCO | Germany | 1 |

Links:https://www.globefindpro.com/products/58328.html

-

Automatic High Speed Blister Packaging Machine BP-1

Automatic High Speed Blister Packaging Machine BP-1

-

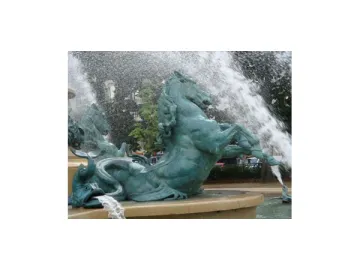

Irregular Bronze Bas-relief

Irregular Bronze Bas-relief

-

Blister Packaging Machine BP-6

Blister Packaging Machine BP-6

-

Powder Filling and Four Side Sealing Packing Machine

Powder Filling and Four Side Sealing Packing Machine

-

Automatic Sticker Labeling Machine

Automatic Sticker Labeling Machine

-

Blister Packing Machine BP-3

Blister Packing Machine BP-3

-

Bronze Eagle Sculpture

Bronze Eagle Sculpture

-

Capsule Filling Machine CF-2

Capsule Filling Machine CF-2

-

Aluminum-PVC, ALU-ALU Automatic Blister Packaging Machine BP-5

Aluminum-PVC, ALU-ALU Automatic Blister Packaging Machine BP-5

-

Bronze Horse Sculpture

Bronze Horse Sculpture

-

HLS120 Concrete Mixing Plant

HLS120 Concrete Mixing Plant

-

LED Indoor Light

LED Indoor Light