Master Links

Material: alloy steel integral forging or welding

Classification: long ring, pear shape ring, round ring, composite ring, chain link ring

Safety factor: 4 times

Surface: red painting

Seamless master link Welded master link Pear-shaped master link Seamless master rings Master link sub-assemblies Coupling links

Technical Parameters:

1.Seamless master link

| ltem No | SWL (t) | dimensions (mm) | Weight Each (kg) | ||

| d | B | A | |||

| TH2101 | 2t | φ22 | 90 | 140 | 1.7 |

| TH2102 | 3t | φ26 | 100 | 160 | 2.6 |

| TH2103 | 5t | φ32 | 110 | 190 | 4.6 |

| TH2104 | 8t | φ36 | 120 | 200 | 6.2 |

| TH2105 | 10t | φ40 | 140 | 260 | 9.5 |

| TH2106 | 16t | φ42 | 140 | 260 | 10.6 |

| TH2107 | 20t | φ45 | 160 | 300 | 13.8 |

| TH2108 | 32t | φ50 | 180 | 370 | 20.4 |

| TH2109 | 40t | φ55 | 180 | 390 | 25.9 |

| TH2110 | 60t | φ60 | 220 | 390 | 32.4 |

| TH2111 | 80t | φ70 | 240 | 420 | 48.4 |

2. Welded master link

| ltem No | SWL (t) | dimensions (mm) | Weight Each (kg) | ||

| d | B | A | |||

| TH2121 | 2T | φ25 | 80 | 160 | 2.3 |

| TH2122 | 3T | φ28 | 80 | 160 | 2.9 |

| TH2123 | 5T | φ32 | 100 | 180 | 4.3 |

| TH2124 | 8T | φ36 | 130 | 220 | 6.7 |

| TH2125 | 10T | φ40 | 130 | 220 | 8.4 |

| TH2126 | 16T | φ42 | 150 | 280 | 11.3 |

| TH2127 | 20T | φ45 | 150 | 280 | 13.1 |

| TH2128 | 32T | φ50 | 180 | 350 | 19.7 |

| TH2129 | 40T | φ55 | 180 | 350 | 24.1 |

| TH2130 | 60T | φ65 | 200 | 400 | 39.2 |

| TH2131 | 80T | φ75 | 200 | 400 | 57.8 |

3. Pear-shaped master link

| ltem No | SWL (t) | dimensions (mm) | Weight Each (kg) | |||

| d | A | R1 | R2 | |||

| TH2141 | 2t | φ25 | 120 | 15 | 35 | 1.8 |

| TH2142 | 3t | φ28 | 140 | 20 | 45 | 2.6 |

| TH2143 | 5t | φ32 | 160 | 25 | 60 | 4.1 |

| TH2144 | 8t | φ36 | 175 | 25 | 60 | 5.5 |

| TH2145 | 10t | φ40 | 220 | 30 | 65 | 8.2 |

| TH2146 | 16t | φ42 | 220 | 35 | 80 | 9.5 |

| TH2147 | 20t | φ45 | 300 | 40 | 85 | 13.4 |

| TH2148 | 32t | φ50 | 300 | 40 | 85 | 16.9 |

| TH2149 | 40t | φ55 | 300 | 45 | 100 | 22.8 |

4. Seamless master rings

| ltem No | SWL (t) | dimensions (mm) | Weight Each (kg) | |

| d | A | |||

| TH2161 | 2t | φ22 | 120 | 1.7 |

| TH2162 | 3t | φ26 | 140 | 2.6 |

| TH2163 | 5t | φ32 | 160 | 4.6 |

| TH2164 | 8t | φ36 | 175 | 6.4 |

| TH2165 | 10t | φ40 | 220 | 9.7 |

| TH2166 | 16t | φ42 | 220 | 10.7 |

| TH2167 | 20t | φ45 | 250 | 13.9 |

| TH2168 | 32t | φ50 | 300 | 20.3 |

| TH2169 | 40t | φ55 | 330 | 27.0 |

| TH2170 | 60t | φ60 | 330 | 32.6 |

| TH2171 | 80t | φ70 | 360 | 49.0 |

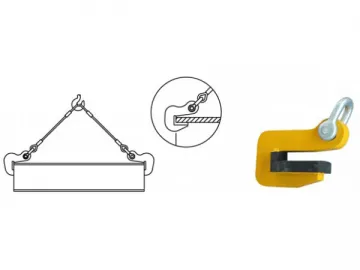

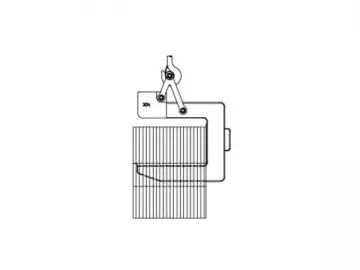

5. Master link sub-assemblies

| ltem No | SWL (t) | Dimensions (mm) | |||||

| A | B | d | A1 | B1 | d1 | ||

| TH2201 | 2t | 140 | 80 | 25 | 60 | 32 | 14 |

| TH2202 | 3t | 160 | 80 | 28 | 65 | 36 | 16 |

| TH2203 | 5t | 180 | 100 | 32 | 80 | 45 | 18 |

| TH2204 | 10t | 220 | 130 | 40 | 100 | 55 | 22 |

| TH2205 | 20t | 280 | 150 | 45 | 110 | 65 | 28 |

| TH2206 | 32t | 350 | 180 | 50 | 120 | 70 | 35 |

| TH2207 | 40t | 350 | 180 | 50 | 140 | 80 | 40 |

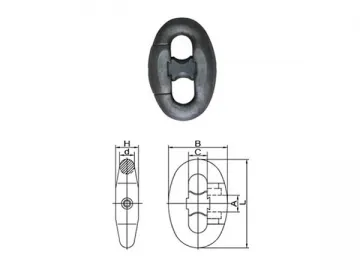

6. Coupling links

| ltem No | Nominal (in) | SWL | Dimensions (mm) | Chain Diameter (mm) | ||||

| (t) | (Lbs) | A | B | D | E | |||

| TH2221 | 1/4 | 1.5 | 3 , 500 | 9 | 48 | 20 | 16 | φ8-10 |

| TH2222 | 5/16 | 2 | 4,500 | 10 | 54 | 22 | 17.5 | φ10-12 |

| TH2223 | 3/8 | 3.2 | 7,100 | 13 | 63 | 26 | 22 | φ12-14 |

| TH2224 | 1/2 | 5.4 | 12 , | 16 | 87 | 36 | 29 | φ14-16 |

| TH2225 | 5/8 | 8.2 | 18,100 | 19 | 105 | 44 | 36 | φ18-20 |

| TH2226 | 3/4 | 12.5 | 28,300 | 24 | 120 | 52 | 41 | φ22-24 |

| TH2227 | 7/8 | 15 | 34,200 | 27 | 140 | 58 | 51 | φ25-28 |

| TH2228 | 1 | 21 | 47,700 | 31 | 152 | 63 | 57 | φ30-36 |

| TH2229 | 1 1/4 | 32 | 72,300 | 38 | 188 | 77 | 65 | φ38-45 |

Standards for Discarding:

There are obvious permanent deformations.

The sectional wear volume of body is more than 10% of the original size.

Any crack appears on the shackle body.

It fails the tensile testing.

Production Process:

Round billet inspection---cutting---Die forging(welding)---heat treatment---grinding shot blasting ---machining--- assembly---tensile testing---surface coating ---storage

Scan QR to Read

Links:https://www.globefindpro.com/products/58537.html

Links:https://www.globefindpro.com/products/58537.html

Recommended Products