High Strength Bow Shackle

High-Strength C-Steel Shackle(American Standard shackle)(Bolt Shackle)

Features: small size, light weight, high safety factor, easy to operate

Material: alloy steel integral forging

Safety factor: 1t-25t is 6 times, 25t is more than 4 times

Appearance: Type A is internal thread, Type B is outer nut

Surface: painting, zinc plating

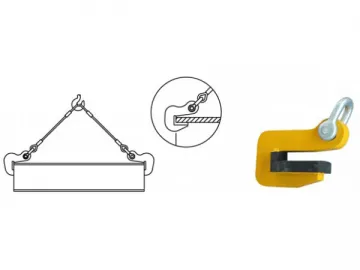

Drawing:

Technical Parameters:

| item No | SWL | Nominal Size | (mm) Dimensions | (kg) Weight Each | ||||

| d | A | B | C | H | ||||

| TH1201 | 1 | 3/8 | 10 | 12 | 16 | 26 | 36 | 0.2 |

| TH1202 | 2 | 1/2 | 13 | 16 | 21 | 33 | 46.5 | 0.43 |

| TH1203 | 3.25 | 5/8 | 16 | 20 | 27 | 42 | 58 | 0.83 |

| TH1204 | 4.75 | 3/4 | 19 | 22 | 32 | 51 | 69.5 | 1.3 |

| TH1205 | 6.5 | 7/8 | 22 | 25 | 37 | 58 | 82.5 | 1.8 |

| TH1206 | 8.5 | 1 | 25 | 30 | 43 | 68 | 92.5 | 2.8 |

| TH1207 | 9.5 | 1-1/8 | 29 | 32 | 46 | 74 | 106.5 | 3.85 |

| TH1208 | 12 | 1-1/4 | 32 | 36 | 52 | 83 | 117 | 5.3 |

| TH1209 | 13.5 | 1-3/8 | 35 | 38 | 57 | 89 | 133 | 6.7 |

| TH1210 | 17 | 1-1/2 | 38 | 42 | 60 | 98 | 146 | 8.8 |

| TH1211 | 25 | 1-3/4 | 44 | 50 | 73 | 127 | 175 | 14.6 |

| TH1212 | 35 | 2 | 51 | 56 | 83 | 146 | 195 | 22 |

| TH1213 | 45 | 2-1/4 | 56 | 65 | 95 | 160 | 233 | 31 |

| TH1214 | 55 | 2-1/2 | 64 | 70 | 105 | 184 | 266 | 43.3 |

| TH1215 | 60 | 2-3/4 | 70 | 78 | 100 | 200 | 289 | 57 |

| TH1216 | 85 (80) | 3 | 76 | 82 | 121 | 229 | 335 | 73 |

| TH1217 | 100 | 3-3/8 | 86 | 92 | 131 | 232 | 356 | 100 |

| TH1218 | 120 | 3-1/2 | 90 | 95 | 154 | 241 | 372 | 114 |

| TH1219 | 150 | 4 | 102 | 108 | 160 | 254 | 390 | 165 |

| TH1220 | 175 | 4-1/4 | 108 | 120 | 170 | 260 | 410 | 190 |

| TH1221 | 200 | 4-3/4 | 120 | 130 | 184 | 280 | 440 | 283 |

| TH1222 | 250 | 5 | 127 | 140 | 210 | 330 | 470 | 350 |

| TH1223 | 300 | 6 | 152 | 170 | 220 | 345 | 520 | 470 |

| TH1224 | 400 | 7 | 178 | 190 | 230 | 360 | 572 | 670 |

Standards for Discarding:

There are obvious permanent deformations or the pivot pin cannot rotate freely.

The sectional wear volume of buckle body or the pivot pin is more than 10% of the original size.

Any crack appears on the shackle body.

Shackle cannot lock.

Shackles fail the test.

Production Process:

Round billet inspection---cutting---Die forging---heat treatment---grinding shot blasting ---machining--- assembly---tensile testing---surface coating ---storage

Links:https://www.globefindpro.com/products/58544.html