Aviation Industry

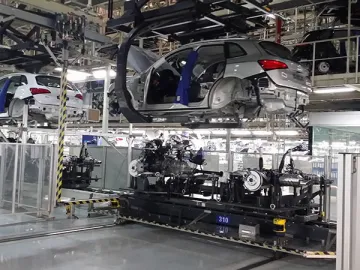

Aircraft fuselage is assembled by tens of thousands of parts. Large parts include front, middle and back fuselage, wings, tail, undercarriage, control system, power unit, etc. Usually, these parts come with large size and are manufactured in different factories. Finally, what control methods can be used to assemble efficiently and precisely are always the main concern of airplane manufacturers. It is an undoubted fact, however, that, bridge CMM machines are indispensable for this industry.

Typical Case

Customer Introduction

AVIC Xi'an Aircraft Industry (Group) Company Ltd. (XAC) is a large sized high tech manufacturing enterprise in aviation industry. It mainly produces large and medium sized military and civil airplanes, luxury buses, building materials and electronic devices. In addition, this company manufactures 14 vertical tails for BOEING 737 passenger airplanes per month and provides subcontracting services for international airlines in Europe and Canada.

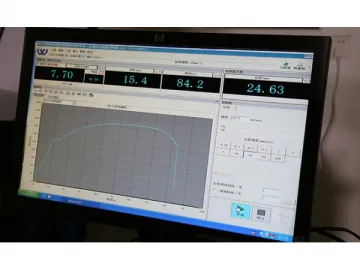

In XAC, precision measurement equipment combining CAD/CAM/CAI technologies enable parts measurement and tooling to conduct synchronously, thus shortening the aircraft development cycle. Based on our Royal series bridge coordinate measuring machines with touch-trigger probe system and RATIONAL DMIS CAD software, measurement time is considerably reduced, ensuring high flexibility in dimensional measurement.

Links:https://www.globefindpro.com/products/58835.html