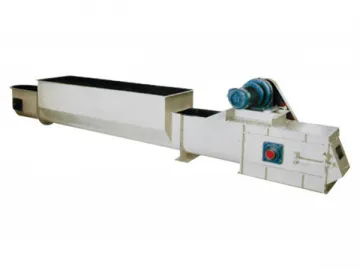

Conveyor

Built to industry-leading specifications, the screw conveyor features a unique design as bearings for head and tail sections are installed outside the housing. Rotary center shaft can come with either a sliding contact bearing or a rolling contact bearing. Both bearings are sealed to keep out dust. A clean-up device is installed at the outlet end.

Also called auger conveyor, the screw conveyor is quiet running, easy to repair and suitable for a variety of bulk materials in food processing and animal feed pelleting industries. Customers can choose the position of inlet and outlet.

Technical Specifications| Model | 200 | 250 | 315 | 400 | 500 |

| Screw Diameter | 200 | 250 | 315 | 400 | 500 |

| Screw Pitch | 200 | 250 | 315 | 355 | 400 |

| Rotational Speed (r/min) | 100 | 90 | 80 | 71 | 63 |

| Throughput (m/h) | 13 | 22 | 31 | 62 | 98 |

| Rotational Speed (r/min) | 80 | 71 | 63 | 56 | 50 |

| Throughput (m/h) | 10 | 18 | 24 | 49 | 78 |

| Rotational Speed(r/min ) | 63 | 56 | 50 | 45 | 40 |

| Throughput (m/h) | 8 | 14 | 19 | 39 | 62 |

| Rotational Speed (r.min) | 50 | 45 | 40 | 36 | 32 |

| Throughput (m/h) | 6.2 | 11 | 15.4 | 31 | 50 |

Operating typically in low decibels, the TGSU series scraper conveyor runs smooth and straight, all the while leaving no residuals inside the trough. Quality bush roller chains, paired with small-pitch sprockets at both ends, ensure stable transmission. Scraper plate scrapes dust off the trough.

Alarms would go off in the event of clogging or chain breakage. A simple structure facilitates repair and operation. Packing is used for stationary seal which increases the life of bearing all the while keeping dust from leaking outside. Ideal for horizontal material transfer.

Technical Specifications| Model | TGSU16 | TGSU20 | TGSU25 | TGSU32 | TGSU36 | TGSU40 | TGSU |

| J-style Trough Diameter (m) | 160 | 200 | 250 | 320 | 360 | 400 | 500 |

| Chain Pitch(mm) | 60 | 60 | 60 | 80 | 80 | 80 | 100 |

| Speed(m/s) | 0.35-0.6 | 0.35-0.6 | 0.35-0.6 | 0.35-0.7 | 0.35-0.7 | 0.35-0.7 | 0.35-0.7 |

| Throughput (t/h) | 10-25 | 25-30 | 30-45 | 45-80 | 80-120 | 120-150 | 150-260 |

Links:https://www.globefindpro.com/products/58927.html