Counter-flow Cooler

Qidong counter-flow cooler plays a big part in animal feed pelleting and works with an airflow that moves opposite to the pellet flow. This pellet cooling method allows hot pellets to cool down gradually rather than abruptly, so cracks in the surface become less of an issue. The use of airlock feeder provides a large opening and allows a large volume of air to enter for excellent cooling results.

Technical Parameters of Counter-flow Cooler

Technical Parameters of Counter-flow Cooler

Features of Counter-flow Cooler

1. Slide valve is used to effectively discharge the cooled pellets with minimum residue.

2. Pellet temperature after cooling should be 3℃-5℃ higher than room temperature. Finished pellets have a proper moisture content so they don't grow mold, are hard enough to withstand rough handling, and make it easier to store and transfer.

3. The top of the counter-flow cooler is made of stainless steel for excellent corrosion resistance and long service life.

4. Hot air only contacts hot pellets while cooled pellets pass by cool air in opposite flows. This avoids surface cracks in pellets.

| Model | SLlN1.5 | SLlN2.5 | SLlN4 | SLlN6 | SLlN8 |

| Cooling Volume | 1.5 ㎥ | 2.5 ㎥ | 4 ㎥ | 6 ㎥ | 8 ㎥ |

| Main Power | 0.75KW | 1.1KW | 1.5KW | 1.5KW | 1.5KW |

| Air Lock Power | 0.55KW | 0.55KW | 0.55KW | 0.75KW | 0.75KW |

| Output Capacity | 3T/H | 5T/H | 10T/H | 15T/H | 20T/H |

| Cooling Time (min.) | Not less than 10-15min. | ||||

| Temperature After Cooling | 3 ℃ -5℃ higher than room temperature | ||||

| Air Volume ( ㎥ / min.t ) | 34 | ||||

Scan QR to Read

Links:https://www.globefindpro.com/products/58928.html

Links:https://www.globefindpro.com/products/58928.html

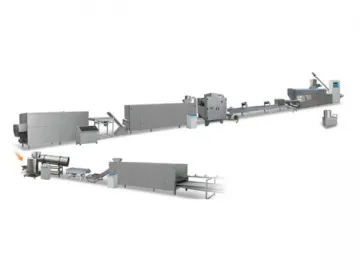

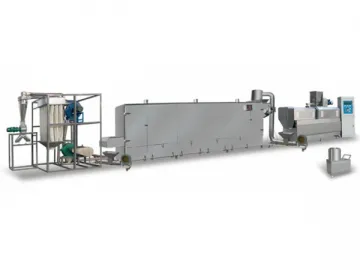

Recommended Products

Hot Products