Sustainability

Pre-stressed kraft paper is made by breaking from traditional papermaking methods and adding warp and weft yarns to the pulp to integrate the materials. As a result, the strength of the kraft paper is significantly improved while still reducing the amount of pulp consumed, saving resources.

Raw material gathering and the manufacturing process for PP synthetic paper will not damage the environment. The paper is recyclable after usage, and even if it is destroyed using incineration after usage, it will not emit harmful gas as its base materials are carbon and oxygen elements. As a result, secondary pollution is prevented, allowing the synthetic paper to meet today's environmental protection standards. By replacing the paper and wood with plastic, the synthetic is made without wood and natural plant fiber, saving forests and reducing environmental pollution.

In order to create a cleaner planet and ensure the health of people everywhere, we have developed environmentally friendly products that save trees and reduce carbon emissions.AS a result, we have enhanced product performance and reduced production costs. Resources are saved and the environment is protected by doing so. Any waste water generate during the production process is reused after being put through an internal recycling purification device, saving water resources and once again, protecting the environment.

We also advocate for a variety of outdoor environmental protection activities. We plant trees every spring with our employees to encourage them and other organizations to join us in environmental protection activities, promote environmental awareness and achieve a sustainable development with a harmonious relationship between humans and nature.

Links:https://www.globefindpro.com/products/59007.html

-

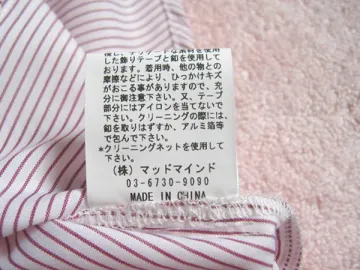

PP Synthetic Paper for Clothing Tag

PP Synthetic Paper for Clothing Tag

-

PVD Vacuum Coating Machine for Surgical Instruments

PVD Vacuum Coating Machine for Surgical Instruments

-

Carbon Black Pelletizing

Carbon Black Pelletizing

-

Vacuum Coater for Metal Hardware

Vacuum Coater for Metal Hardware

-

Vacuum Metallizer for Plastic Christmas Ball

Vacuum Metallizer for Plastic Christmas Ball

-

Promotion Items

Promotion Items

-

Vacuum Coating Machine for Door Handle

Vacuum Coating Machine for Door Handle

-

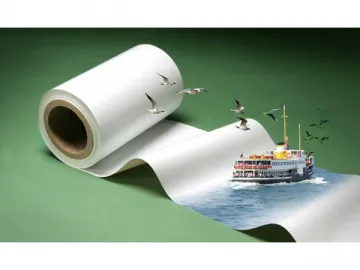

PP Synthetic Paper for Airline Baggage Tag

PP Synthetic Paper for Airline Baggage Tag

-

Synthetic Paper (for Printed Label)

Synthetic Paper (for Printed Label)

-

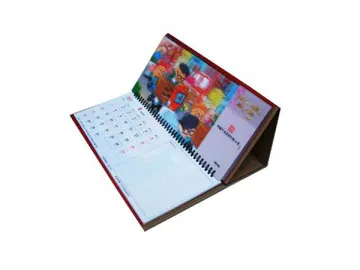

PP Synthetic Paper for Calendar

PP Synthetic Paper for Calendar

-

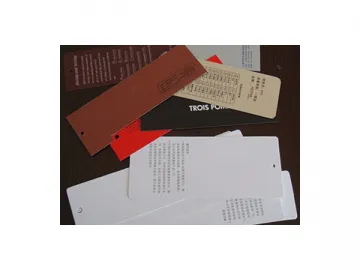

PP Synthetic Paper for Product Tag

PP Synthetic Paper for Product Tag

-

Kraft Paper (for Wall Sealing Tape)

Kraft Paper (for Wall Sealing Tape)