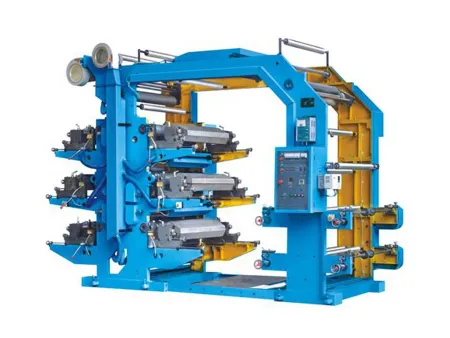

High Speed Flexo Printing Machine

Video

Technical Parameters

Technical Parameters

Standard Unwinder & Rewinder Double unwinder & rewinder: Hydraulic unwinder and friction rewinder

5kg automatic tension brake Tension sensor

Automatic tension controller Printing System Doctor Blade and Anilox Roller. We employ Japan-manufactured doctor blades and anilox rollers, which produces results that are even in terms of ink distribution.

Adjust the plate roller using the motor. The motor controls all the rollers. Printing parts: with popular design and high flexibility

Eletrical components: PLC control and cameras

Our newly developed high speed flexo printing machine features a thicker steel plate construction for improved stability, ensuring precise printing results.

The photocell can capture printed images clearly, thus allowing us to assess print quality swiftly.

An automated registration system controlled by a motor is utilized to simplify color adjustments, eliminating the need for manual labor. This system allows for the adjustment of color to be done directly from a computer.

| Model | YTB-600 | YTB-800 | YTB-1000 | YTB-1200 |

| Max. effective printing width (mm) | 560 | 760 | 960 | 1160 |

| Max. web width (mm) | 600 | 800 | 1000 | 1200 |

| Max. printing speed (m.min) | 80-100 | 80-100 | 80-100 | 80-100 |

| Max. mechanical speed (m/min) | 110 | 110 | 110 | 110 |

| Max. diameter of roll material (mm) | Ф650 | Ф650 | Ф650 | Ф650 |

| Roll material inner diameter (mm) | ф76 | ф76 | ф76 | ф76 |

| Repeated length (mm) | 191-914 | 191-914 | 191-914 | 191-914 |

| Accuracy (mm) | ±0.15 | ±0.15 | ±0.15 | ±0.15 |

| Thickness of flexible plate (two-sided adhesive paper included, mm) | 2.38 | 2.38 | 2.38 | 2.38 |

| Power of heater (kW) | 15 | 20 | 23 | 28 |

| Total power (kW) | 25 | 30 | 35 | 40 |

| Weight (kg) | 4500 | 4800 | 5000 | 5500 |

| Dimensions(mm) | 5.5×1.7×2.5 | 5.5×2×2.5 | 5.5×2.1×2.5 | 5.5×2.3×2.5 |

5kg automatic tension brake Tension sensor

Automatic tension controller Printing System Doctor Blade and Anilox Roller. We employ Japan-manufactured doctor blades and anilox rollers, which produces results that are even in terms of ink distribution.

Adjust the plate roller using the motor. The motor controls all the rollers. Printing parts: with popular design and high flexibility

Eletrical components: PLC control and cameras

Scan QR to Read

Links:https://www.globefindpro.com/products/597.html

Links:https://www.globefindpro.com/products/597.html

Recommended Products

-

4/6 Color Flexographic Printing Machine

4/6 Color Flexographic Printing Machine

-

PP Blown Film Machine

PP Blown Film Machine

-

Three Layer Blown Film Machine

Three Layer Blown Film Machine

-

6 Color CI Flexo Printing Machine

6 Color CI Flexo Printing Machine

-

2 Color Flexographic Printing Machine

2 Color Flexographic Printing Machine

-

Single-layer Blown Film Machine

Single-layer Blown Film Machine

-

High Speed Blown Film Machine with Double Rewinder

High Speed Blown Film Machine with Double Rewinder

-

ABA Three Layer Blown Film Machine

ABA Three Layer Blown Film Machine

-

Automatic Side Seal Loop Handle Bag Making Machine

Automatic Side Seal Loop Handle Bag Making Machine

-

Plastic Hem Folding Machine

Plastic Hem Folding Machine

-

Two Color Striped Blown Film Machine

Two Color Striped Blown Film Machine

-

ABA Three Layer Blown Film Machine

ABA Three Layer Blown Film Machine

Hot Products