Equipment

In addition to our strong production capacity of mold components, we also have successively purchased and imported a number of advanced equipment from mainland China, Italy, Germany, USA, Japan, etc. We own more than 400 sets of major equipment for our die part production, covering 219 metal-cutting equipment, 126 key processing equipment, large horizontal machining center, medium-sized vertical and horizontal machining centers and CNC milling machine. Having widely used the computer application technology, we have successfully enabled our product development and technology upgrade to enter the modernized fast track.

Our cutting equipment for manufacturing mold accessories includes CNC lathe, instrument lathe, standard lathe, automatic sawing machine and drilling machine; our grinding equipment consists of centerless grinder, cylindrical grinder, inner bore grinder and honing machine; our equipment for heat treatment contains high-frequency hardening machine, carburizing furnace, Chinese style tempering machine and vacuum furnace; our testing equipment includes cylindrical grinding detector, 2D measuring instrument and inner bore measuring instrument; etc.

Our Headquarters in Shenzhen

1. Coordinate Grinder

The grinder can process materials high hardness, such as hardened steel and cemented carbide; Also, it can process brittle materials, including glass and granite. The grinder can make not only precision grinding on materials with very small surface roughness, such as precision guide pillar and guide bushing; but also high efficiency grinding, including high-rate grinding.

1. Coordinate Grinder

2. Milling Machine

3. Surface Grinder

4. Lathe

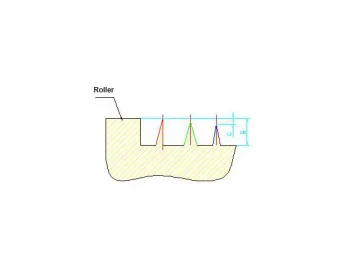

5. Punching Machine

6. Internal and External Grinding Machine

7. CNC Milling Machine

8. Centerless Grinding Machine

9. Coordinate Measuring Machine

The coordinate measuring machine has its three axles equipped with air supply brake switch and inching device, which can achieve precision single-axis drive. Also, its high-performance data acquisition system specially uses a reliable manual coordinate system. The coordinate measuring machine can be used for measuring the precision of the molding equipment, work fixtures, auto parts, electronic appliances and die parts, such as guide pillar, guide bushing, punch pin, etc. Moreover, it is applicable to the product design, measurement of gear and blade and machinery manufacturing.

10. Rockwell Hardness Tester

The Rockwell hardness tester is used to measure material's hardness number. Featuring fast test speed, easy operation and non-destructive property, the Rockwell hardness tester can be applied to plane workpiece and curved workpiece with the curvature from Φ50mm to infinity. It is also suitable for measuring the hardness number of ferrous metals, non-ferrous metals and non-metallic materials.

11. 2D Measuring Instrument

The 2D measuring instrument can be used to measure any physical dimension on the plane, including the diameter, radius, length, angle, width, height, depth, distance from point to point, distance from point to line, the center distance and so on. Having the imported high-precision P-class linear guide and precision mute grinded lead screw, our 2D measuring instrument can achieve high precision and accurate positioning.

Other Equipment

Stamping Die, Guide Pillar and Guide Bushing Factory

Warehouse of Raw Material

Production Workshop

Product Testing Area

Warehouse of Finished Products

Ejector Pin and Ejector Sleeve Factory

Factory Overview

Production Workshop

Product Testing Area

Links:https://www.globefindpro.com/products/59772.html