R&D and Equipment

Exceptional R&D Capacity and Advanced Equipment

First established in 1972, our company has become a reliable supplier of special air conditioning unit which has established comprehensive and scientific R&D, manufacture, quality control and management and marketing systems as well as several professional laboratories such as Enthalpy potential laboratory and hydraulic lab that, officially recognized by the CNAS, help ensure the precision and reliability of our equipment. Supported by an experienced, committed and profession staff, we have dramatically strengthened our hard and soft powers and laid a solid foundation for further development and future success.

Exceptional R&D Capacity

Based our years' development, we have already established a brilliant R&D team which consists of 45 experienced engineers and has mastered several nuclear technologies for product development such as the computerized CAD technique and 3D design tool technique. Moreover, our company has established an overseas research center inJapan which definitely helps us provide more reliable advanced air conditioning units to customers around the world.

Advanced Laboratories

Since its establishment, HICON has being exerting efforts in the establishment of professional laboratories. It has built up several advanced laboratories which significantly promote the research and development of new products, product properties test and quality control.

Noise and vibration

measurement Laboratory

(outside)

Noise and vibration

measurement Laboratory

(inside)

Performance Test Device

for Air Cooled Chiller

Unit(lab)

Performance Test Device

for Water Cooled Chiller

Unit(Lab)

Airflow laboratory

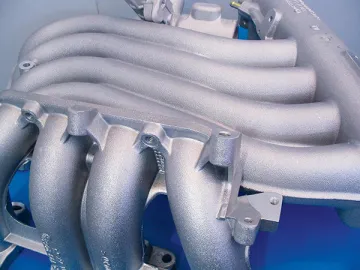

Advanced Equipment and Production Lines

To facilitate the manufacture of rich sorts of air conditioning units and devices, we have purchase some world-class processing equipment such as the metal penal process equipment which includes a comprehensive set of CNC shearing machines, bending machine and 7 maching centers.

AMADA CNC Bending

Machine

AMADA Punch

Equipment

CNC Shearing Equipment

Deep Throat Bending

Machine

Horizontal Tube

Expander

400T Hydraulic Machine

500kW Deutz Generator

At the same time, we has introduced two advanced automatic spraying lines each of which integrates the acid pickling, pre-dying, spraying and after-drying and other processes. What is also facilitating to our production is our compressive production line for heat exchanger which includes such reliable equipment as fin punching machine, mechanical expansion machine, copper tube cutting machine and welding machine.

Automatic Spraying Lines

Automatic Production

Line for Heat Exchanger's

Fins

CNC Turret Punch

Automatic U-shape Tube

Bender (Hairpin Machine)

Metal Panel Production

Line

Air-cooled Heat Pump

Production Line

Screw Machine

Production Line Terminal Coil

Production Line

Advanced Testing Equipment

In order to ensure the good quality and reliable performance of our products, we have purchased several advanced testing apparatuses and devices and established detailed guiding principles for the whole testing work. Before the delivery, each air conditioning unit or device will go through at least 50 testing items such as the tests for appearance, boundary dimensions, spraying, components, wire connection and liquid leakage and so forth.

Testing Center for Host

Machine

Testing Center for

Terminal Devices

Laboratory for Modular

Aircon Unit

Testing Equipment for

Air-cooled Chiller Unit

Links:https://www.globefindpro.com/products/59927.html