Steering System

Induction Hardening Machine for Steering System

We have mature heat treatment technology and 16 years of industrial experience to provide you with a matching heat treatment processing equipment for the steering system. It ensures minimum deformation, and improves the torsion, bending and abrasion resistances of the parts.

The steering system comes in the recirculating ball type and the rack and pinion type. Both types have many parts that need the induction hardening process, such as the steering rack, pinion shaft, worm shaft, and the control valve sets. The heat treatment on these parts should limit the deformation to the smallest, otherwise the deformation will bring troubles to subsequent processing, and even resulting in substandard products

We are professional to provide you with a variety of tailored induction heat treatment solutions. To know more, welcome to contact us.

Induction Hardening Machine for Rack

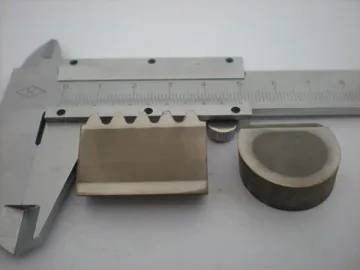

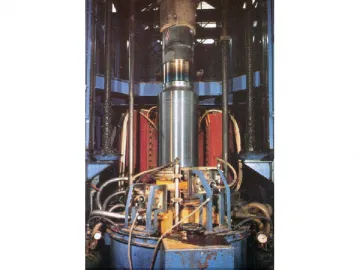

The induction hardening machine for rack is dedicated to the continuous induction scan hardening of rack teeth and bar. The machine is fitted with a laser displacement sensor to detect the deformation of parts. The horseshoe inductor can automatically perform scan hardening on well-positioned parts. During the continuous processing, the hardening position of workpiece will be corrected from time to time, to avoid distortion and bending due to uneven heating. The whole process can be unattended, very suitable for continuous quenching mass production in factories.

Configuration and Parameters

Power supply: HKTP160kW/6-30kHz

HKHP1000/2 2-Station Conductive Quenching Machine

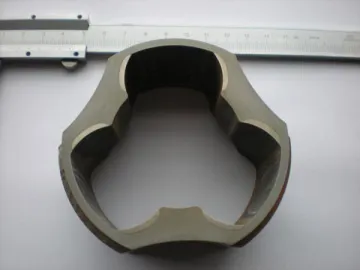

The HKHP1000/2 2-station conductive quenching machine is used for the quenching of rack teeth and back. The conductive quenching will bring high hardness to the teeth, while bring high toughness to the center. The machine is fitted with two stations to realize the simultaneous hardening on teeth and back. The process ensures the uniform, stable hardening and consequently the improved material properties.

Configuration and Parameters

Power supply: HKSP120KW/100-200KHZ

4-Station Rotary Induction Quenching Machine for Pinion

The 4-station rotary quenching and tempering production line can perform induction heat treatment on steering gear control valve or steering pinion shaft. Such small modulus gear is usually not easy to get a profiling hardened layer in quenching process. Instead, the teeth tips will be through hardened, thus increasing the degree of deformation of parts, and consequently increasing the subsequent processing time. Our profiling hardening technology special for the small modulus gears will save unnecessary trouble for you.

Configuration and Parameters

Power supply:

HKSP40kW/400kHz 1 unit hardening

HKTP100kW/100kHz 1 unit hardening

HKTP50kW/4kHz 1 unit tempering

Workpiece length: 80mm-200mm

Workpiece diameter: Φ10mm-Φ30mm

window.onload =function() {setItemByDivId('container','one|two|three|four|five|six|seven','etw_link','color:fff; background:#107bfc;','color:#fff; background:#b6b3b3','setclass');}

Links:https://www.globefindpro.com/products/60145.html

-

PLC (Programmable Logic Controller)

PLC (Programmable Logic Controller)

-

Powertrain System

Powertrain System

-

Dual frequency Induction Hardening Machine for Large Size Roller

Dual frequency Induction Hardening Machine for Large Size Roller

-

Suspension System

Suspension System

-

HKHT6000 Long Bar Induction Hardening and Tempering Machine

HKHT6000 Long Bar Induction Hardening and Tempering Machine

-

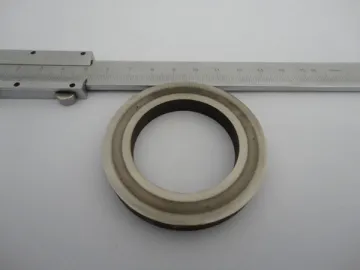

HKVP1500 Small Size Bearing Raceway Induction Hardening Machine with Slope

HKVP1500 Small Size Bearing Raceway Induction Hardening Machine with Slope

-

Trainings

Trainings

-

Inverter Drive for Reel Stand

Inverter Drive for Reel Stand

-

Metal Hardening and Tempering

Metal Hardening and Tempering

-

Large-Sized Shaft Induction Hardening Machine

Large-Sized Shaft Induction Hardening Machine

-

Corrugated Roller

Corrugated Roller

-

Samples of Hardened Parts

Samples of Hardened Parts