Ice Tube Machine

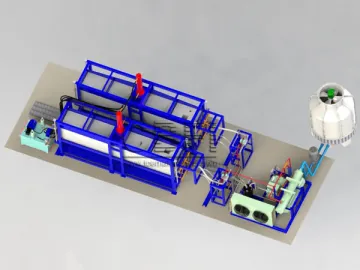

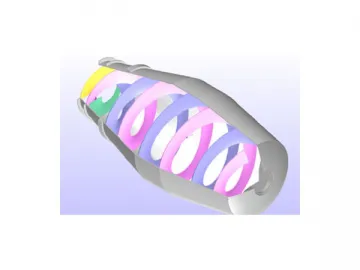

Ice tube machine can produce cylindrical edible ice. This machine for ice making contains evaporator composed of multiple stainless steel tubes among which refrigerant flows. With the help of water divider, water is allowed to flow up to down helically in those tubes. Ice will be formed in the process of water flowing.

With digital pressure controller, mechanical pressure controller and time relay, the ice forming speed can be strictly controlled to prevent the stainless steel tubes from cracking. When the ice is formed, the ice making system will provide heat to the evaporator to make the formed ice melt a little and drop automatically. At the same time, the dropping ice will be cut into cylindrical ice cubes with the length of 3-5mm.

Since it occupies little space and has high heat exchanging efficiency, ice tube machine is favored by customers.

Features of Tube Ice

Tube ice is a kind of hollow cylindrical ice with external diameter of 22mm, 28mm, 35mm and length ranging from 25mm~42mm. Its internal diameter is usually 5~10mm and can be adjusted by controlling the ice making time.

Tube ice produce by our ice tube machine has the characteristics of high thickness and transparency, thaw-resistance, long storage time and fine air permeability.

Features of Ice Tube Machine

1. Our ice making equipment adopts 3D simulation installation technology and has compact structure. It is easy to operate and maintain.

2. In this ice processing machine, all the parts that are in contact with the water are made of SUS304 stainless steel. Impurity and metal ions that may influence the transparency of the ice will be automatically removed through the circulating water tank.

3. Thanks to special alloy material and unique thermal treatment, the evaporator of our ice tube machine has excellent heat transmission performance.

4. PLC computer modularized automatic control system is used to control the whole ice making process.

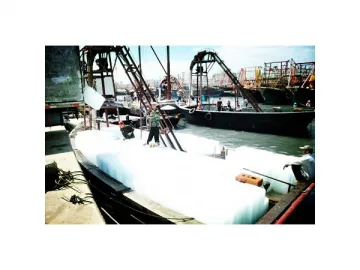

5. The ice tube produced by our ice making equipment can be eaten directly and is suitable for cooling drinks, wine, cakes and other foods.

Note: Our company provides tube ice machine with daily production volume ranging from 1ton to 20 ton. If you have any special requirement, please contact us.

5ton/day cube ice machine

Working Principle

When the refrigerating system of the ice tube machine is working normally, water in the lower tank will be transported to the inlet of the upper tank. Divided by the water dividing device, the water will helically flow down along the inner wall of the heat exchange tube and exchange heat with the refrigerant outside the tube. As the temperature is declining, some of the water will become ice tube adhering to the inner wall of the heat exchange tube. The remained water will flow back to the lower water tank. The water circulation helps reduce cold energy loss.

After a certain period of time, water circulation will stop and the refrigerating system of the ice tube machine will switch into ice dropping mode and the ice cutting mechanism will start operating. High pressure hot refrigerant gas on the outer surface of the heat exchange tube will exchange heat with the tube ice in the inner wall of the heat exchange tube and make the ice tube melt a little. Then the ice tube will automatically drop into the ice cutting mechanism by gravity to be cut into shorter ice tubes.

Accessories

Our ice tube machine adopts German Bitzer fluoride-free compressor, South Korean LG electrical components and Italian Castal solenoid valve. All the accessories we use comply with the EU RoHs directive. With a housing made of high-quality stainless steel, our ice making equipment is corrosion-resistant and durable.

Technical Parameters

| Model | Ice making Capacity | Rated Power | Circulating Water Pump Power | Cooling Water Pump Power | Cooling Fan Power | Ice Cutter Motor Power | Machine Dimension | Machine Weight |

| No. | Ton/24h | kW | kW | kW | kW | kW | W×H×L (mm) | kg |

| TV10 | 1.0 | 3.69 | 0.37 | 1.1 | 0.18 | 0.75 | 1320×950×1800 | 900 |

| TV20 | 2.0 | 7.11 | 0.55 | 1.1 | 0.18 | 0.75 | 1400×1100×1800 | 1200 |

| TV30 | 3.0 | 9.68 | 0.55 | 1.1 | 0.37 | 0.75 | 1500×1100×1950 | 1500 |

| TV50 | 5.0 | 17.47 | 0.55 | 1.5 | 0.75 | 0.75 | 1600×1250×2200 | 1800 |

| TV100 | 10.0 | 30.89 | 0.75 | 2.2 | 1.5 | 1.5 | 1700×1300×2200 | 3500 |

| TV150 | 15.0 | 42.6 | 1.5 | 2.2 | 2.2 | 1.5 | 3000×1500×2200 | 4250 |

| TV200 | 20.0 | 53.2 | 1.5 | 2.2 | 2.2 | 1.5 | 3500×1500×2200 | 6500 |

Running Conditions

Supply water temperature: 23°C

Evaporating temperature: -12°C

Condensing temperature: 40°C

Power supply frequency: 50Hz

Note

The above parameters are for reference only. The actual ice output of the ice machine will vary with the variation of the temperature of water and environment.

window.onload =function() {setItemByDivId('container','one|two','etw_link','color:fff; background:#cf271c;','color:#fff;background:#0f98dc','setclass');doget('/loadByJs.php?type=loadByReg&page=/3-1-1ton-tube-ice-machine/163955&start=start&end=end','setresult')}

Links:https://www.globefindpro.com/products/60812.html

-

Concrete Cooling

Concrete Cooling

-

MBB Series Ice Block Machine

MBB Series Ice Block Machine

-

Ice Cube Machine

Ice Cube Machine

-

ABI Series Automatic Ice Block Machine

ABI Series Automatic Ice Block Machine

-

Cooling in Chemical Industry

Cooling in Chemical Industry

-

Ice Plate Machine

Ice Plate Machine

-

TV30 Tube Ice Machine Exported to Malaysia

TV30 Tube Ice Machine Exported to Malaysia

-

MB150 Ice Block Machine in Malaysia

MB150 Ice Block Machine in Malaysia

-

Fish Preservation

Fish Preservation

-

3ton/day Cube Ice Machine Exported to Yemen

3ton/day Cube Ice Machine Exported to Yemen

-

R & D

R & D

-

MB120 Ice Block Machine Exported to the Philippines

MB120 Ice Block Machine Exported to the Philippines