Ice Plate Machine

Ice output

Ice output

Plate ice thickness

Small plate ice

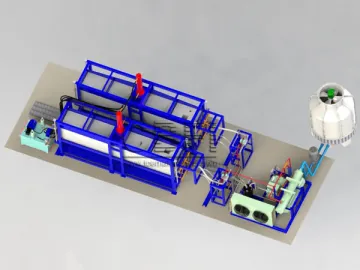

The ice plate machine is a new product developed combining the partially frozen storage technology. Centrally controlled by microcomputer, this product is easy to operate.

Our ice making machine can produce ice in plate shape. The evaporator adopts flat-wall liquid film heat exchange technology and the technology of ice forming on both sides of the heat exchange tube. The S-shape heat exchange tube is designed based on the hot runner. Hot gas ice dropping technology is also employed in our ice plate machine.

The ice making system contains ice forming system and ice dropping system that can work independently. The advanced ice making system makes ice making cycle short. The whole plate ice machine has excellent performance of anti-corrosion, impact resistance and pressure resistance. In addition, our product is also energy-saving. The power consumption it takes to produce 1 ton ice is just 60kW.h. Thus our ice plate machine has obvious advantages compared with other types of ice making equipment.

Parts

Performance Advantages

1. High-quality evaporator made of stainless steel is adopted in our ice plate making equipment to guarantee powerful ice making performance.

2. As a new product, our plate ice machine can save more than 30% energy.

3. Our ice plate machine contains highly intelligent working systems and is free from mechanical wear.

4. Equipped with a PLC programmable monitoring system, our plate ice making equipment can work independently without being supervised by specially-assigned worker.

Application

Due to its advantage of high density, cleanliness, cooling capacity and adjustable size, plate ice plays a more and more important role in industry, agriculture and fishing.

Our ice plate machine can produce plate ice which is widely used in the fields of fishery production, aquatic products processing, pelagic fishing, transportation, meat product processing, supermarket fresh-keeping, food processing, medicine, chemical dyeing, fermentation engineering, construction project, concrete cooling, mine cooling, ice storage engineering and paper making industry.

Technical Parameters

| Model | Ice Making capacity | Rated Power | Circulating Water Pump Power | Cooling Water Pump Power | Cooling Fan Power | Machine Dimension | Machine Weight |

| No. | Ton/24h | kW | kW | kW | kW | W×H×L (mm) | kg |

| HYF10 | 1.0 | 3.69 | 0.37 | 1.5 | 0.37 | 1900×1370×1660 | 860 |

| HYF20 | 2.0 | 7.11 | 0.55 | 1.5 | 0.55 | 2400×1600×1700 | 1200 |

| HYF30 | 3.0 | 9.68 | 0.55 | 2.2 | 0.75 | 2400×1600×1800 | 1350 |

| HYF50 | 5.0 | 17.47 | 0.55 | 2.2 | 1.5 | 2500×1860×1950 | 1500 |

| HYF100 | 10.0 | 26.6 | 5.5 | 4 | 1.5 | 2500×2200×2150 | 2500 |

| HYF150 | 15.0 | 48.3 | 7.5 | 5.5 | 2.2 | 4000×1800×2200 | 3800 |

| HYF200 | 20.0 | 63 | 7.5 | 7.5 | 3.75 | 4000×2040×2200 | 4650 |

Running Conditions

Supply water temperature: 23°C

Evaporating temperature: -12°C

Condensing temperature: 40°C

Power supply frequency: 50Hz

Note

The above parameters are just for reference. Actual ice production volume of the ice machine will vary slightly with the variation of water temperature and ambient temperature.

Project cases

Modelwindow.onload =function() {setItemByDivId('container','one|two','etw_link','color:fff; background:#cf271c;','color:#fff;background:#0f98dc','setclass');doget('/loadByJs.php?type=loadByReg&page=/4-1-1ton-plate-ice-machine/163962&start=start&end=end','setresult')}

Links:https://www.globefindpro.com/products/60818.html