PU Sandwich Panel Production Line

A.

B.

C. Preheating room

D. Foam system

E. Double belt conveyer

F. Band saw cutter

G. Cooling system

H. Automatic stacking machine

I. Packing machine

Construction

The PU sandwich panel production line incorporates uncoiler with coil feeding car, cut-to-length band saw, caterpillar laminating machine, roll forming machine, work platform for roll former, conveyor rack, steel pre-heating room, high-pressure mixing and pouring device for two-component PU, hydraulic lifting device, stacker, packing machine, and other configurations.

Instruction

Our Advantages

Currently, there are only 4 countries capable of producing PU sandwich panel production line in the world. Compared with competitors from Italy, German and South Korea, our color steel sandwich panel production line boasts dominant superiorities. Backed up by low manpower cost, strong R&D team, sufficient capital support, and large production scale, we can help you save more expenditures and budgets during PU sandwich panel production for the unit cost of our equipment is lower. Besides, under attentive maintenance, our machine can be used as long as more than 6 years.

Features

Our PU sandwich panel production line is fabricated in line with present development trend of heat insulated metal panel on the international and domestic markets. It can produce flat panel, hidden-type corrugated panel or tailored corrugated panel.

By adopting microcomputer controlled length and quantity counting device as well as field bus communication technology, continuous automation is realized, and operation is more convenient and reliable. There is no doubt that this line is the optimal equipment for metal surface sandwich panel production.

Parameters

1. Production speed of our PU sandwich panel production line: 0-8m/min. (Stepless variable frequency speed regulation is available.)

2. Overall dimension: 128m×18m×6.5m (This dimension excludes cooling system, and specific dimension is customizable.)

3. Installed power: About 350KW

4. Weight: About 200T

5. Maximum theoretical capacity: About 500m2/h

PU Sandwich Panel Introduction

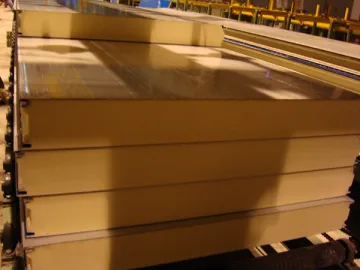

The PU sandwich panel manufactured by our PU sandwich panel production line is new-generation versatile building and decoration material. It comes with a multitude of merits, such as heat preservation, light weight, high strength, excellent watertightness, decorative beauty, short construction time, large load bearing capacity, etc. Thus, it can be applied to industrial and public buildings as workshop, supermarket, warehouse, large-span house, refrigeration house, makeshift house, clean room, air conditioning room and other places.

You will feel surprised that the weight of PU sandwich panel is only one fortieth or one sixtieth of the weight of common brick material. Hence, this panel is indeed ideal building mate.

Specifications of Panel Produced by Corrugated Panel Production Line

| Thickness (mm) | 40-200 |

| Width (mm) | 600-1200 |

| Length (mm) | 3000-16000 |

| Note: Maximum thickness of roof panel is 150mm, and other specifications can be determined through negotiation. (Please see details on panel drawing). | |

Components

It takes full advantage of feedback control, making for consistent decoiling and roll forming speed. Besides, this color steel coil decoiler is painstakingly designed to ensure that the least amount of labor and time is used for steel coil changing.

When the width of steel plate exceeds desired width, edge cutting device is used to cut the superfluous part of steel plate. This device is unpowered, capable of passive cutting under the pulling force of steel plate. Maximum cutting width is 100mm, and produced scraps will be winded by automatic winder.

After processed by this machine, top and bottom steel plates are presented in male and female joint shape on both sides, providing convenience for subsequent installation and splicing.

After fully mixed, two-component materials will be sprayed onto steel plate by means of mixing head in reciprocating motion.

Its main body is connected by link plate of 1320mm wide, and main body length is 30m. Other lengths are also available. This building material production equipment is capable of top caterpillar band lifting via hydraulic cylinder and guide mechanisms.

High-speed three-phase motor puts bandsaw wheel into motion, which thereby drives PU sandwich panel cutter for cutting.

During cutting, panel is tightly compressed via air cylinder above tool rest.

Our sandwich panel stacker adopts vacuum lifting system for panel lifting without damage to panel. It enables automatic sandwich panel stacking and comes with dedicated rack for storing unqualified panel scraps. Meanwhile, encoder is used for position detection, making for neat and orderly panel stacking.

User Guide

window.onload =function() {setItemByDivId('container','one|two|three1','etw_link','color:fff; background:#0ca7fa;','color:#fff;background:#1e4ea7','setclass');doget('/loadByJs.php?type=loadByReg&page=/2-8-user-guide/164511&start=start&end=end','setresult')}

Links:https://www.globefindpro.com/products/61034.html